Online Masterclass on Environmental Testing for Aerospace & Defense

Siemens Digital Industries Software invites you to join us for a free, educational online Master Class on Environmental Testing for Aerospace & Defense.

Aerospace and Defense industries are in constant transition, developing new products embracing new technologies and materials, in ever shorter times, while still maintaining the highest levels of performance and reliability.

This puts a high pressure on Testing teams to perform the qualification tests in shorter time, providing more insights than before, and integrating better with simulation teams.

This online master class covers all aspects of vibration and acoustic qualification testing for components as well as full structures. Next to this, more advanced topics like multiple axis testing and tailored testing are explained. There are also dedicated sessions on modal testing, model correlation, virtual testing and micro-vibrations.

8 morning live sessions of 60 min (session 7 - 90 min) are foreseen for this event:

- Session 1 : Basics of vibration test -November 20th 2020, 10 am CET

What is the main purpose of environmental testing? Introduce the properties and application domains of each environmental application. - Session 2 : Dynamic Environmental testing of components - November 24th 2020, 10 am CET

Certification and qualification of products require specific dynamic tests using external excitation - shock, vibration and noise. Understanding the key parameters behind any control algorithm is critical to a successful test. - Session 3 : Vibration qualification testing of aerospace components and satellites - November 27th 2020, 10 am CET

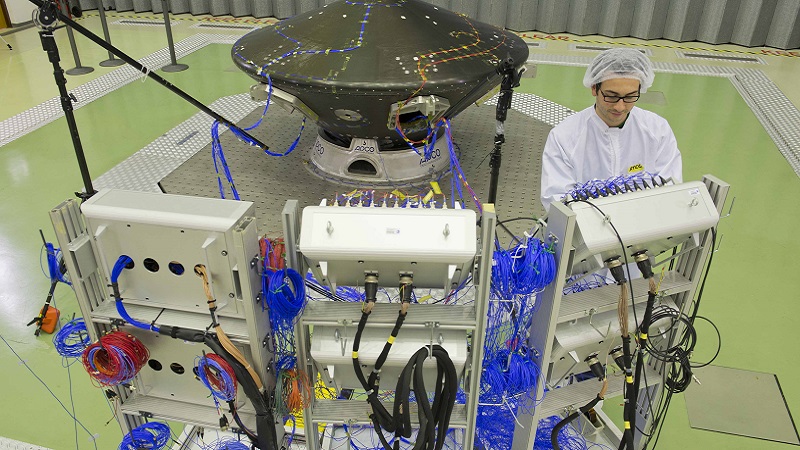

Mechanical qualification tests happen on one-of, very expensive mockup/prototype or the actual spacecraft, involving a significant risk of damaging the hardware. We will discuss how this can be done with full confidence wihtout comprimising the integrity of the scarce and expensive engineering qualification model or the actual flight model. - Session 4 : Acoustic qualification testing of aerospace components and satellites - December 1st 2020, 10 am CET

The noise levels generated at launch can reach levels up to 146dB or higher inside the fairing and cause structural damages and jeopardize the functionality of instruments and subsystems. Therefore, launcher authorities require spacecrafts also to be qualified for acoustic loading. Both traditional (RFAX) as the new testing method (DFAN)will be discussed. - Session 5 : More realistic, advanced and accelerated vibration tests by MIMO testing - December 4th 2020, 10 am CET

The need for time-efficient testing procedures, and the guarantee of an accurate replication of the operational environment are two driving factors in the environmental testing community. MIMO control strategies for dynamic environmental testing can provide the required flexibility to design test campaigns that safely comply with these two key drivers. - Session 6 : Tailored Testing with Mission Synthesis to avoid over- and under testing - December 8th 2020, 10 am CET

The purpose of mission synthesis is to design the optimal test. A balance between severity and accuracy needs to be found. The test should give confidence that it is severe enough to produce those failures likely to occur under normal operating conditions, while avoiding too high test levels that tends to result in costly over-design of the itemoal of mission synthesis is to design the optimum test. A balance between sevirity and accuracy needs to be found. The test needs to give the confidence that it is severe enough to produce those filures that are likely to occur during normal operaating conditions, while avoiding. - Session 7 : Modal Survey for CAE-Model Correlation and virtual shaker testing for de-risking TEST campaigns - December 11th 2020, 10 am CET

To understand the structural dynamics of a spacecraft, the program sometimes requires a Modal survey test. This test aims at test-validating the spacecraft Finite Element structural dynamics model. This model is necessary for the Launcher Coupled Loads analysis process, which assesses the risk of launch load damage. In the field of vibration testing the interaction between the spacecraft being tested and the shaker used to perform the test is a critical issue, because the dynamics of the shaker often couples with that of the test object making its behavior during the physical tests unpredictable. Simulation methods such as “Virtual Shaker Testing” are being developed to be able to foresee these testing difficulties and take countermeasures before running the actual program. - Session 8 : Micro vibration analysis for spacecraft components - December 15th 2020, 10 am CET

High-end optical imaging sensors and lasers are used more and more in satellites. These sensors have high requirements in terms of stability to provide high quality images. However, mechanical devices on the spacecraft such as reaction wheels for attitude control can cause micro-vibrations leading to blurring of images. Therefore, scientific and earth observation missions call for stringent requirements with regard to the micro-vibration environment on-board of a spacecraft.

During these sessions you will learn to:

- Basics of vibration testing

- Perform qualification testing of aerospace components

- Conduct vibration and acoustic testing of fully integrated aerospace structures

- Apply multi axis testing for more realistic and accelerated testing

- Avoid over and under testing by applying tailored testing

- Perform modal testing and conduct model correlation

- Complement physical testing with virtual vibration and acoustic testing

- Handle micro-vibrations for aerospace structures

Join our online Masterclass and receive a full update on the Aerospace and Defense qualification testing process with best-in class methods available, including connection with simulation applications.

For any further information please contact alex.vermeulen@siemens.com

Presenters

Mostapha Choukri and Raphael Hallez have together more than 40years experience in Aerospace & Defense Industry.

Mostapha has more than 20 years of experience at Siemens. Started in product development with a focus on NVH testing solutions. Later moved to providing professional services for the automotive and aerospace industries.

Raphael is an aerospace testing expert. With nearly 20 years at Siemens, he has been involved in many testing and simulation projects with aviation, space and defense companies.

Mostapha Choukri |

Raphael Hallez |