Optimize your PCB assembly business

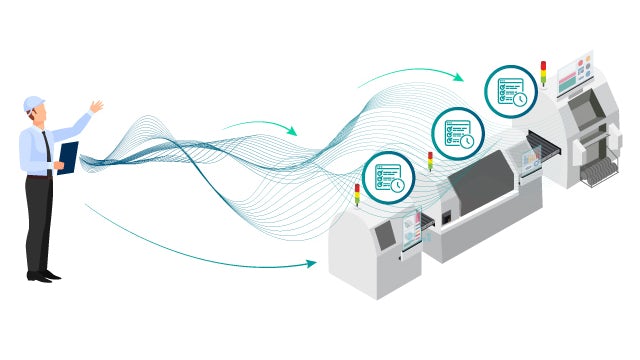

Reduce new product timeline

Simulate the product and process as designed—before actual production begins. Discover design flaws at earlier stages, making corrections quicker and less costly.

Make the most of SMT resources

Ensure your current resources are fully utilized and optimized for improved productivity before investing in expensive new machines and infrastructure.

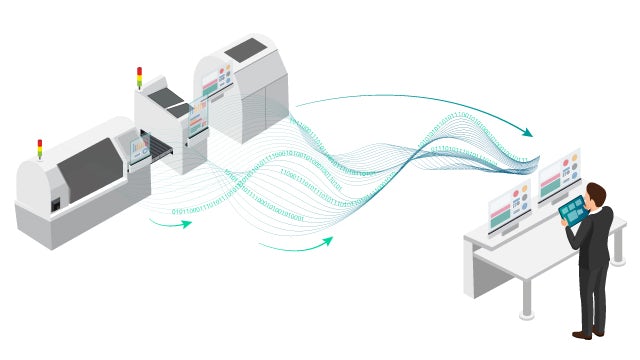

Gain real-time data visibility

Improve your control of operations and material use—knowing what's happening on the shop floor in real-time is crucial to preventing scrap and quality issues.

Egicon

Egicon uses Valor and Opcenter to reduce repair rates by 80 percent while eliminating scrap

Firma:Egicon

Odvětví:Electronics, Semiconductor devices

Umístění:Mirandola, Modena, Italy

Opcenter APS, Opcenter Execution Core, Opcenter Execution Electronics, Opcenter Execution Electronics IoT - MSS (Valor IoT manufacturing - Shopfloor), Opcenter Intelligence for On Premises, Valor Process Preparation

Maximize engineering and manufacturing productivity

Reduce design iterations, improve yield and optimize engineering and manufacturing productivity.

Shift PCB manufacturing knowledge into the design stage

Save time and costs by fixing design issues as they occur during each of the design stages. Don't wait to find the errors after the design is complete.

Accelerate design-to-manufacturing handoff

Get quick, accurate design validation and a smooth handoff through comprehensive collaboration between designers and manufacturers in a secure online platform.

Meet customization challenges

Control the new product introduction (NPI) process to cut down changeover times. Eliminate manual, error-prone processes with a digitalized approach to process engineering.

Automate material delivery within the factory

Cut material waste and inventory with tight machine integration and precise inventory management, and ensure a smooth manufacturing flow.

Use powerful analytics to solve efficiency challenges

Turn the vast amount of data generated in your surface mount technology (SMT) production line into actionable insights with out-of-the-box dashboards that cover every aspect of PCB manufacturing.

Optimize PCB assembly with Valor

As electronics manufacturing accelerates toward high-mix, low-volume production, it is necessary to turn to digitalization for success.