Aprovecha el acceso a los datos en tiempo real

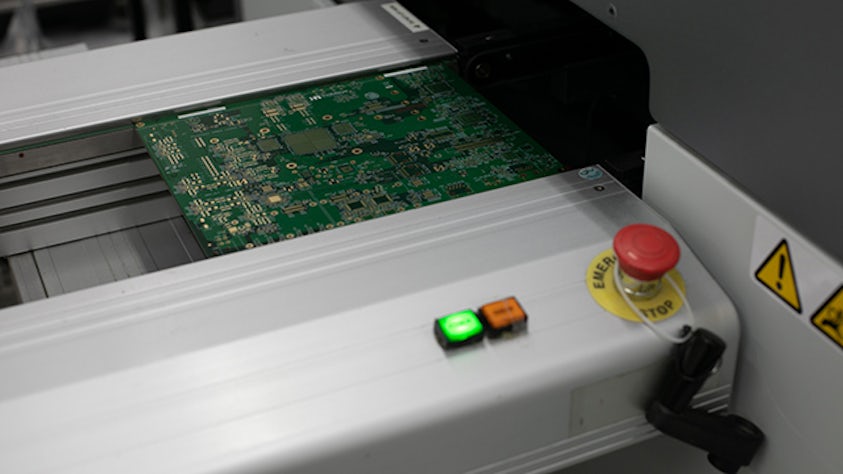

Maximiza la eficiencia del flujo de datos mediante la normalización automática de todos los datos de la planta de producción. Opcenter Connect Electronics recopila datos en tiempo real de todos los procesos o máquinas de la planta de producción combinando y normalizando la adquisición de datos de software unificada y modular. Permite un flujo de datos completo entre la planta de producción y las aplicaciones internas, lo que reduce el tiempo y el esfuerzo.