Zugriff auf Live-Daten nutzen

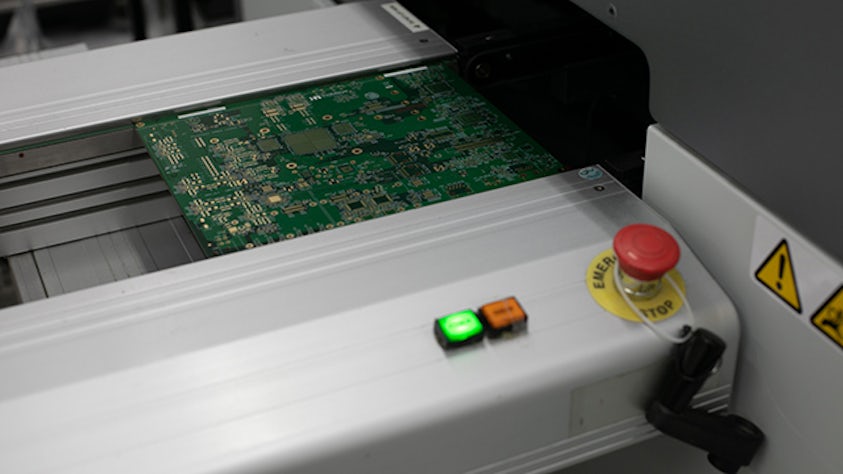

Maximieren Sie die Effizienz des Datenflusses durch die automatische Normalisierung aller Fertigungsdaten. Opcenter Connect Electronics sammelt Live-Daten von jedem Prozess oder jeder Maschine in der Fertigung, indem es eine einheitliche, modulare Software-Datenerfassung kombiniert und normalisiert. Es ermöglicht einen vollständigen Datenfluss zwischen der Fertigung und internen Anwendungen, wodurch Zeit und Aufwand reduziert werden.