Snižte zásoby, zkraťte výrobní cykly a zvyšte úroveň služeb

Díky řešením Opcenter pro plánování výroby a rozvrhování výroby a rozvrhování výroby elektroniky můžete snížit zásoby, zkrátit výrobní cykly a zvýšit úroveň služeb pro své zákazníky.

Zkraťte dobu potřebnou k výrobě a snižte náklady

Rychlé a flexibilní rozvrhování výroby vám pomůže činit informovaná rozhodnutí o krátkodobých a každodenních výrobních úkonech. Pokročilé algoritmy vyvažují poptávku a kapacitu a vytvářejí dosažitelné plány. Maximalizujte efektivitu a minimalizujte dobu potřebnou k výrobě a náklady.

Zlepšete využití zdrojů

Strategicky určete, co a kolik toho vyrobit, kde a kdy to vyrobit a jaké materiály a zdroje jsou přesně zapotřebí. Plánování výroby vám pomůže předvídat potřeby zdrojů, organizovat efektivní využití materiálů, pracovníků a strojů, poskytovat hodnotné služby zákazníkům a zajistit si vyšší ziskovost.

Zajistěte si vyšší efektivitu a produktivitu

Podporujte plánovače při vytváření plánu výroby, který zohledňuje výrobní prognózy, dlouhodobé zakázky a dostupnost a kapacitu výrobních zdrojů. Software pro plánování výroby optimalizuje dlouhodobé a střednědobé plánování vašich výrobních závodů.

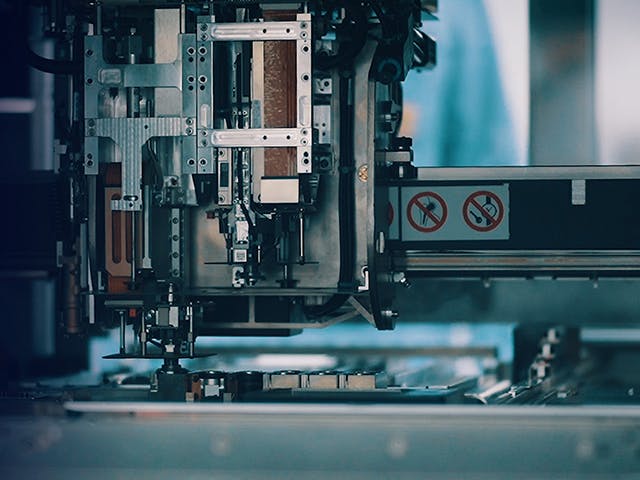

Automatizujte plánování a rozvrhování linek pro výrobu desek s plošnými spoji

V dnešním prostředí sestavování desek s plošnými spoji (PCB) s vysokou rozdílností a malým objemem výroby již ruční plánování výroby nestačí. Chytré plánovací řešení automatizuje proces plánování linek a umožňuje plánovačům soustředit se na přijímání nejlepších rozhodnutí pro optimalizovanou a efektivní výrobu.

Prozkoumat produkty řešení Opcenter pro plánování a rozvrhování

Prohloubení znalostí o řešení Opcenter

Zákaznická podpora

Společnost Siemens nabízí prvotřídní zákaznickou podporu pro řešení Opcenter a všechny své produkty.

Blog řešení Opcenter

Sledujte nejnovější zprávy a zajímavosti o řešení Opcenter na našem blogu.

Komunita řešení Opcenter

Zapojte se do konverzace nebo získejte odpovědi na své otázky týkající se řešení Opcenter.