Understanding Human-Medical Device interactions are foundational to the design of the next generation of medical devices. To fully understand these interactions, device designers are looking to computational modeling to provide more detail than current physical tests allow.

Arguably the most challenging Human-Medical Device interaction is that of realistic heart valve closure. In this webinar, experts from Thornton Tomasetti and Siemens will discuss best practices for performing highly-detailed heart valve simulations using Computational Fluid Dynamics (CFD), with a focus on the Fluid-Structure Interaction (FSI)—the interplay between the flow of blood through the valve, and the valve itself.

Gaining insight into the complex interaction between the fluid (blood) and the structure (the valve)

With roughly 250,000 prosthetic heart valves implanted each year, manufacturers need sophisticated computational models to design the next generation of valves, with the goal of developing valves that last a lifetime and mitigate the need for blood thinning.

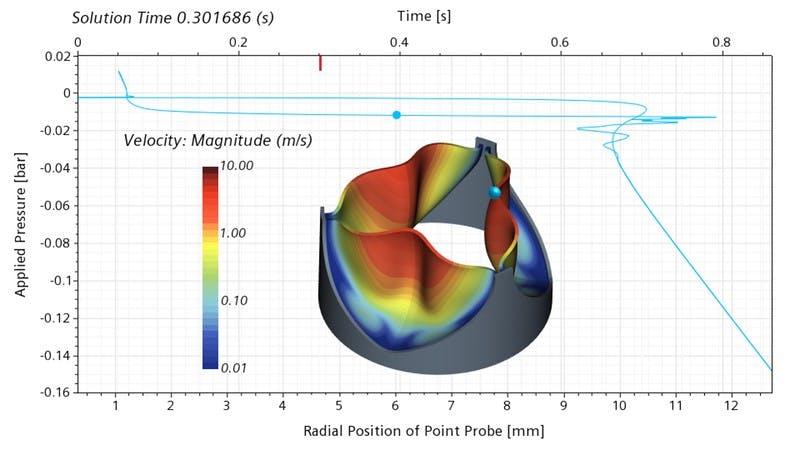

Trileaflet valves operate on the principle of deformation: the three leaflets deflect according to the blood pressure, allowing for blood to flow in one direction but blocking flow in the other. The pressure on the leaflet surfaces leads to the deflection, while at the same time the deflection leads to a change of the flow path. Not only does the flow path change, the flow field changes with it, and so does the pressure on the leaflet surfaces—a classic example of 2-way coupled Fluid-Structure Interaction (FSI).

Coupled CFD/FSI simulations allow you to gain an in-depth understanding of the operational behavior of the valve design and analyze the impact of design changes in a highly efficient manner.

What you will learn in this webinar:

- The clinical background on heart valves, including anatomy, diseases, and treatments

- Current solutions for automated valve modeling, quantification & guidance from medical images

- The challenges of heart valve simulation, and how to stage the simulation project to set you up for success

- Two approaches for coupling the CFD and structural models

- Overcoming challenges in the structural model--such as the snap-through instability

- An efficient and powerful fluid mesh deformation strategy

- Future developments in heart valve FSI simulation

Presenters:

- Ingmar Voigt, Research Scientist, Siemens Healthineers

- Ashley Peterson, PhD, Vice President, Applied Science at Thornton Tomasetti

- Rafael Ritterbusch, Simcenter STAR-CCM+ Technical Product Manager for CAE Integration and Solid Mechanics, Siemens Digital Industries Software