电子书

推动仿真驱动型产品设计在机械行业的创新

阅读时间:7 分钟

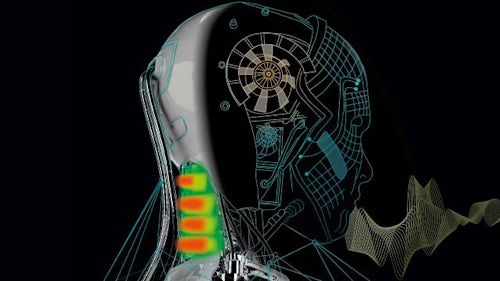

全世界的工厂和车间都在积极寻求数字化转型,从而帮助他们在应对在不断变化的客户需求、采用的新技术和参与全球竞争的创新的方式。此外,这也提高了对于更加智能、灵活、可配置且自动化工业机械设备的需求。工业机械企业需要制定新的仿真驱动型产品设计例行方案,才能跟上这些机器不断增长的复杂性能。

设计灵活性与数字孪生

智能性能工程打造的互联数字线程,能够帮助实现设计团队、分析师、生产测试团队以及服务工程师之间信息共享流程的自动化。这让不同团队可以通过最灵活且高效的方式评估产品变型的功能和局限性。

机械性能优化

改进智能机器的性能,需要大量不同的物理场、开展跨学科学科协同,以及运用仿真技术。这让设计师和仿真工程师能够在多种工具之间使用相同模型的同一主要模型概念并保持仿真数据与设计同步。设计与仿真工具之间更好的集成,能够帮助实现新设计创意、设计变更或假设分析场景中机器性能优化折衷工作流的自动化。

借助智能性能工程优化流程与协同

工业机械的开发需要达到生产力、精度、可靠性和效率之间的最佳平衡。能够以数字化方式进行工业机械开发,可以帮助贵公司比竞争对手更加高效地创新并制造更高质量的机器。

免费下载我们的电子书,详细了解智能性能工程如何能够帮助整合设计与仿真流程。