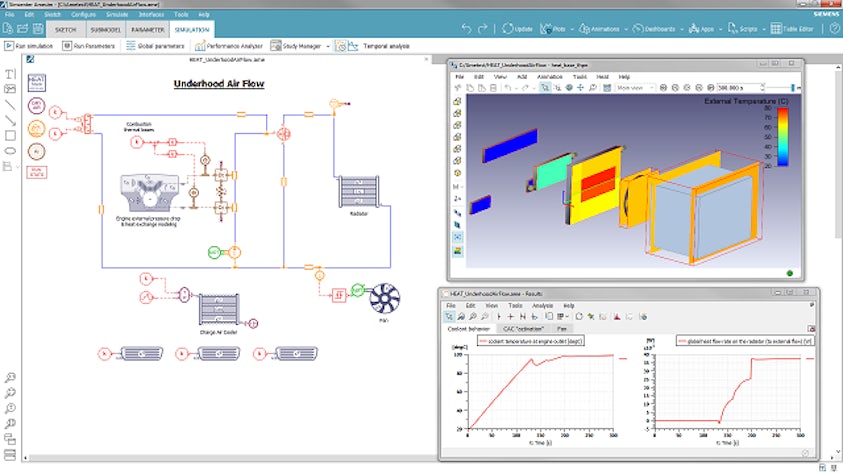

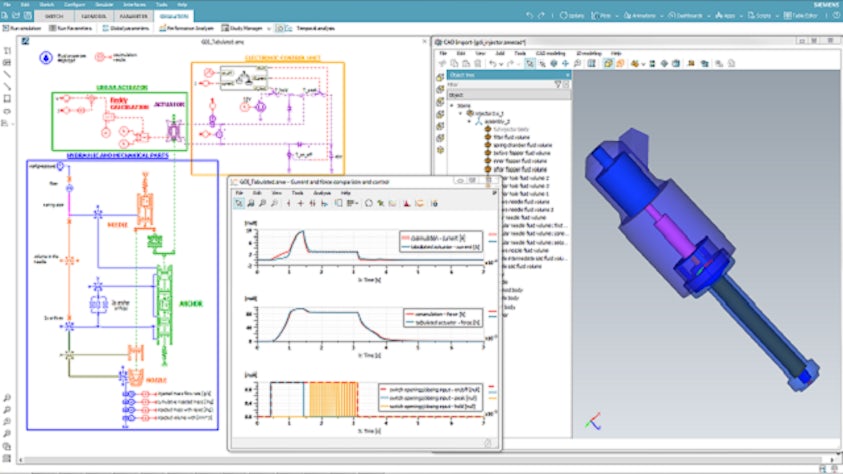

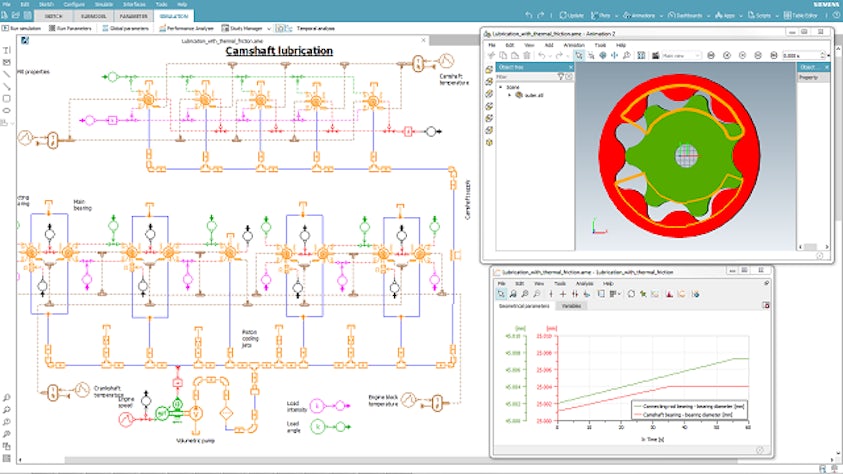

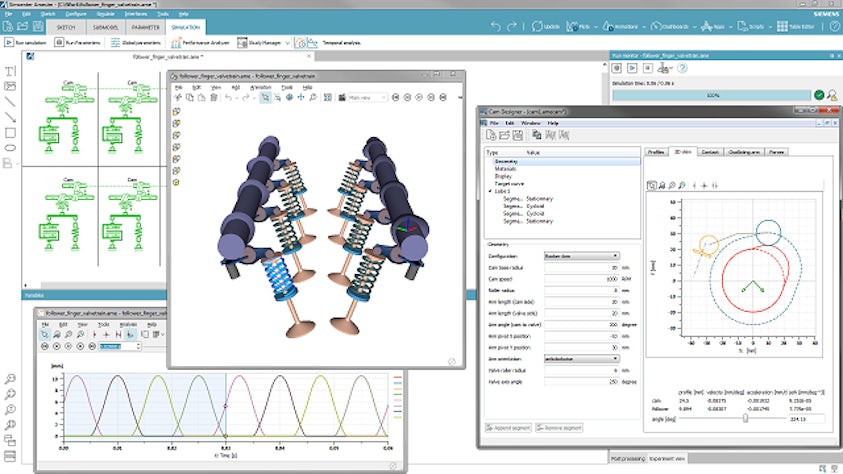

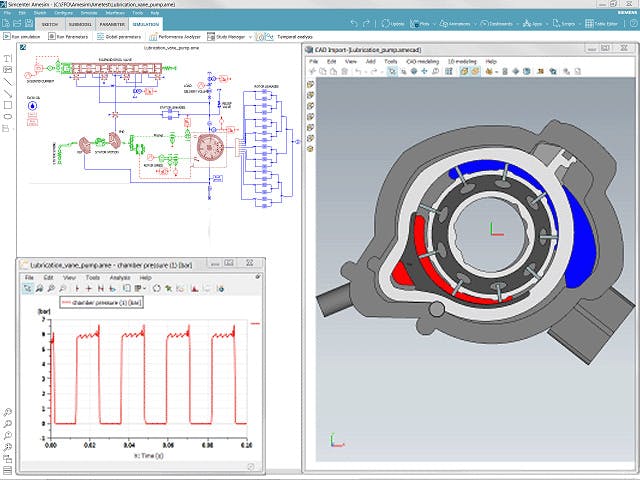

加快包括汽门机构、曲轴系统、燃油喷射以及润滑和冷却回路在内的动力总成子系统的设计过程。无论处在哪一设计阶段,Simcenter 都能为您提供所需的建模能力,并提供适当的细节及精度。您可以研究子系统的性能,并运行不同类型的分析,从流体平衡到包括热方面的瞬态行为,甚至是高频响应。

Simcenter Amesim 可用于调整组件大小,评估和优化系统效率及设计,并验证控制策略。通过评估不同子系统之间以及子系统与燃烧室之间的相互作用,您将能够准备传动环境中组件的集成。通过分析子系统设计对发动机性能、燃油经济性、排放甚至乘客舒适度的影响,您可以确定适当的折衷方案来实现最初的目标。