Simcenter 3D 通过在仿真效率方面的革命性改进,帮助您对复杂的产品性能进行建模和评估。通过在单一仿真建模环境中集成多个物理域,您可以更快地深入了解产品的性能。

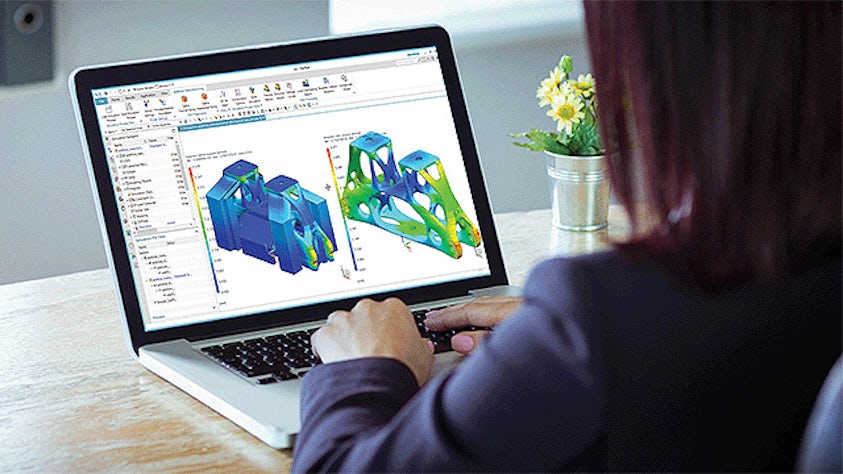

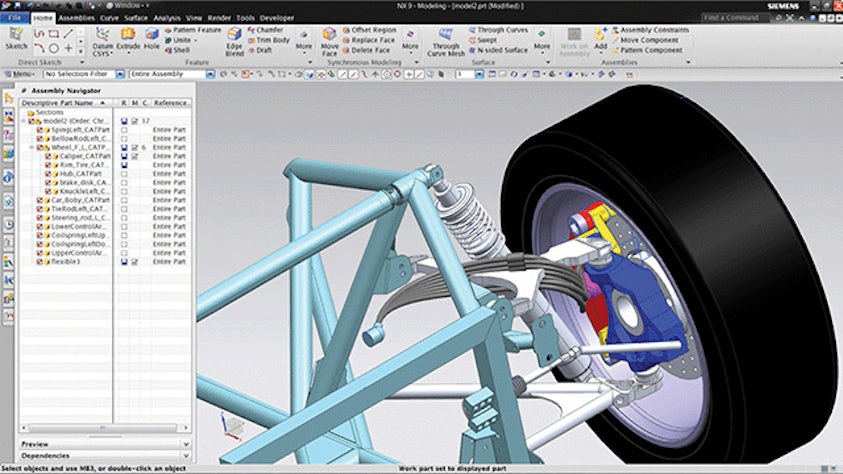

利用通用的工程桌面提高速度

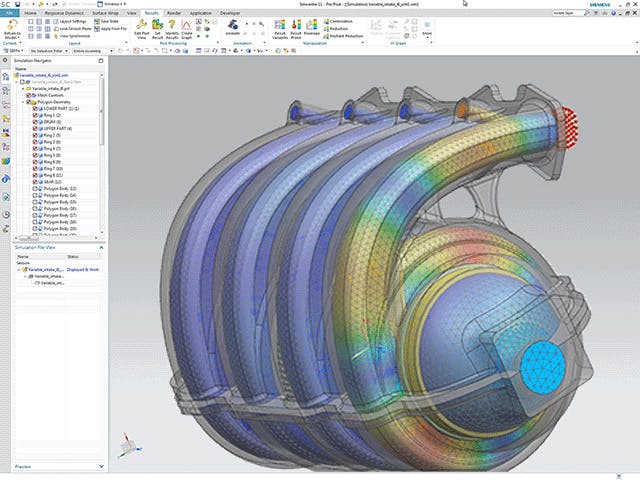

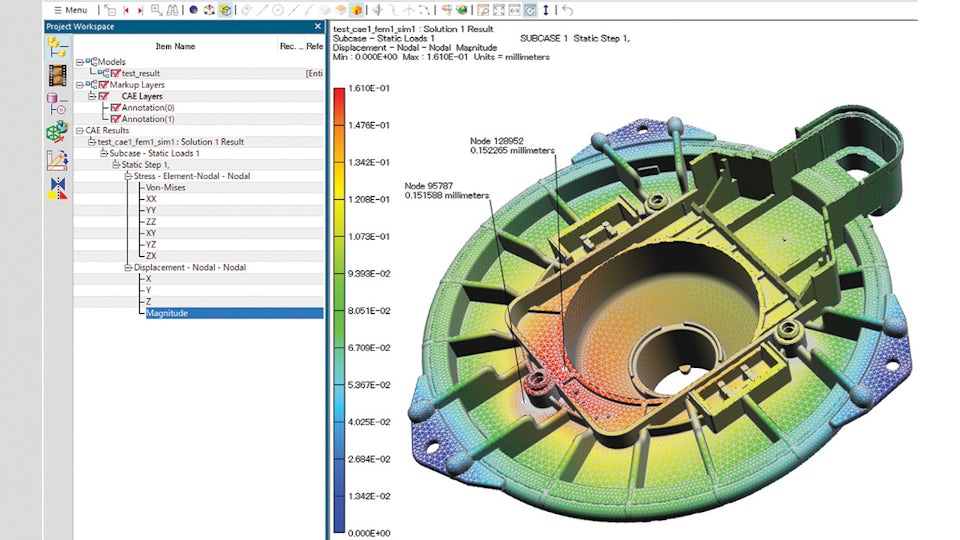

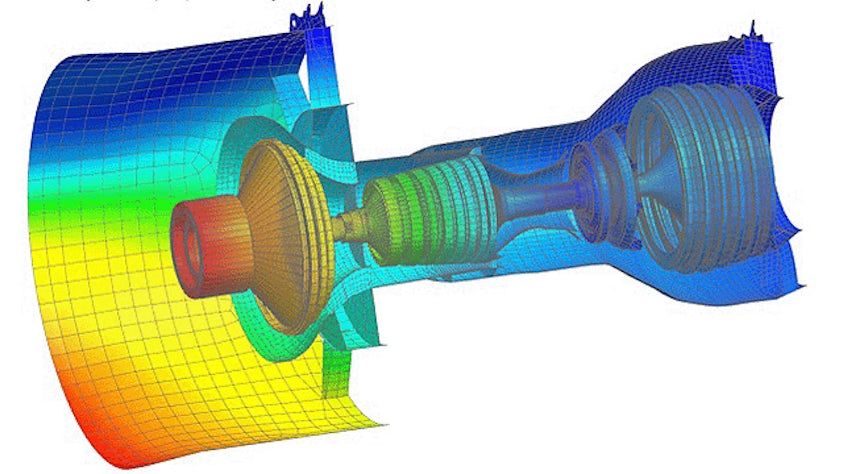

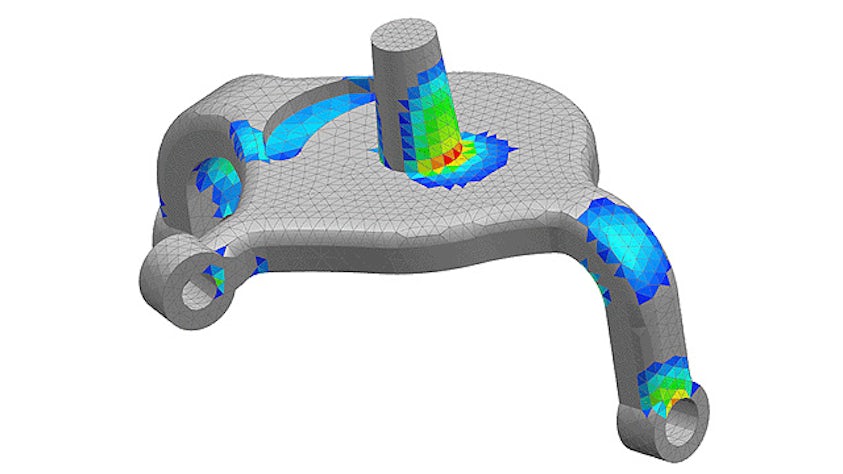

Simcenter 3D 是一个集成环境,您可以在其中执行所有 CAE 预处理和后处理。出色的几何图形操作工具可帮助您直观地从任何来源去除特征和抽象计算机辅助设计 (CAD) 几何体。全面的网格划分和建模工具支持多种仿真应用,并为您提供将分析模型与设计数据相关联的独特功能。这可以帮助您加快枯燥的建模过程,并使分析模型与新近设计同步。

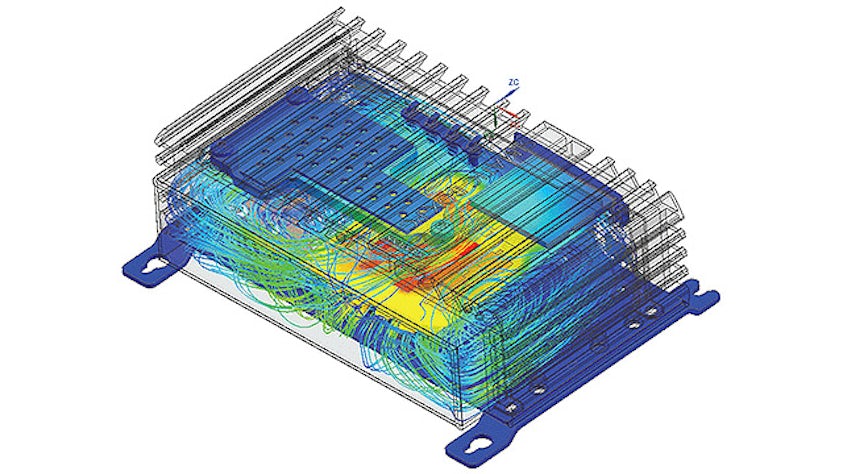

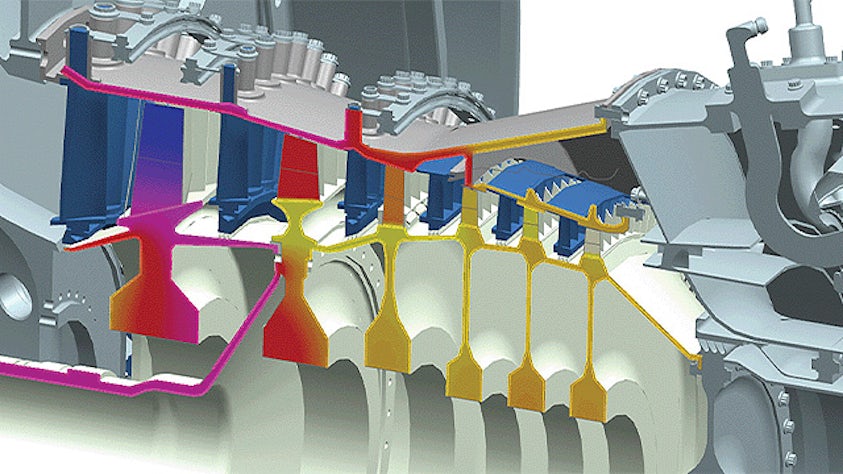

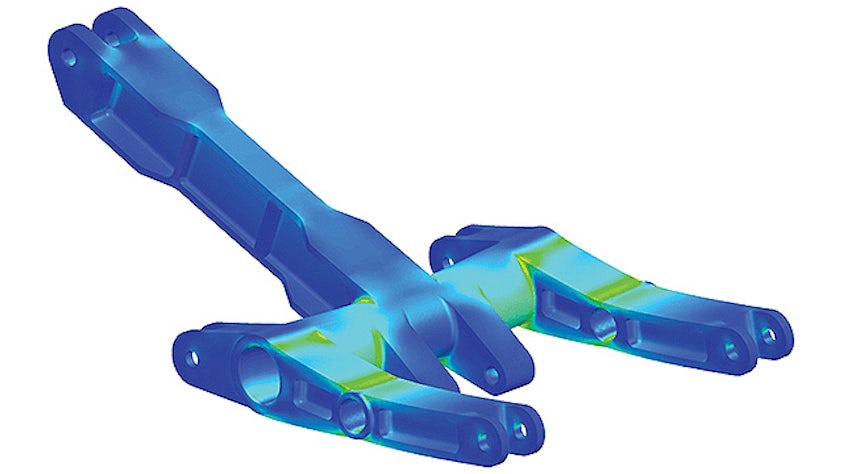

通过仿真多物理场现象对复杂性进行建模

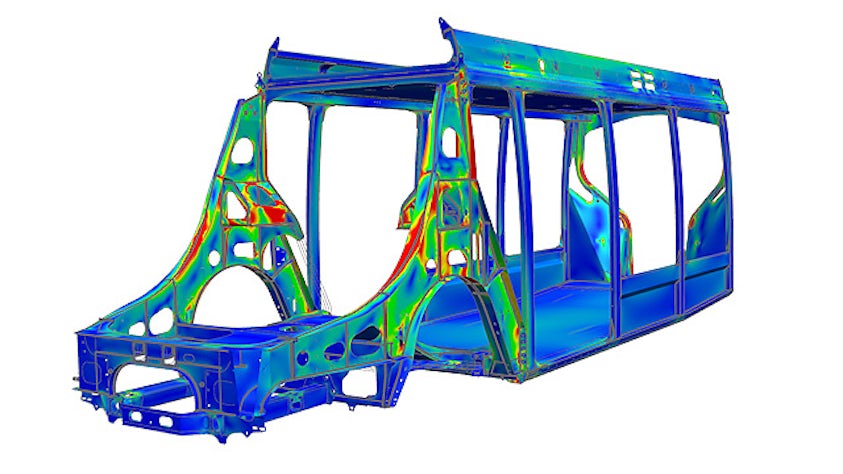

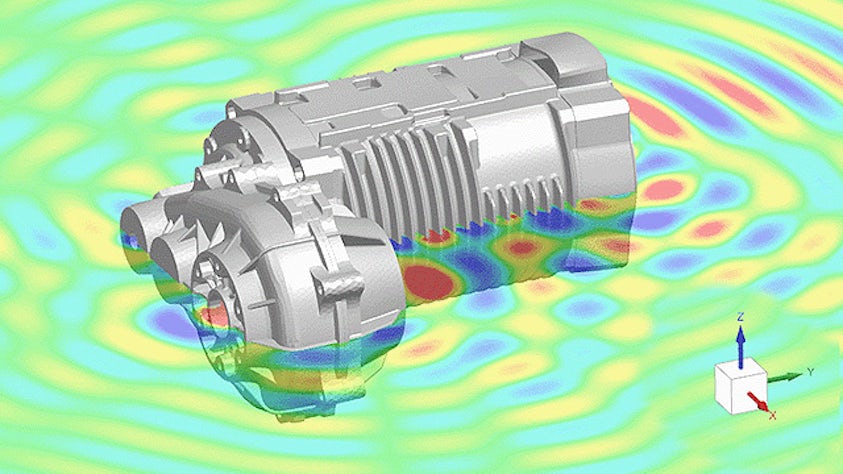

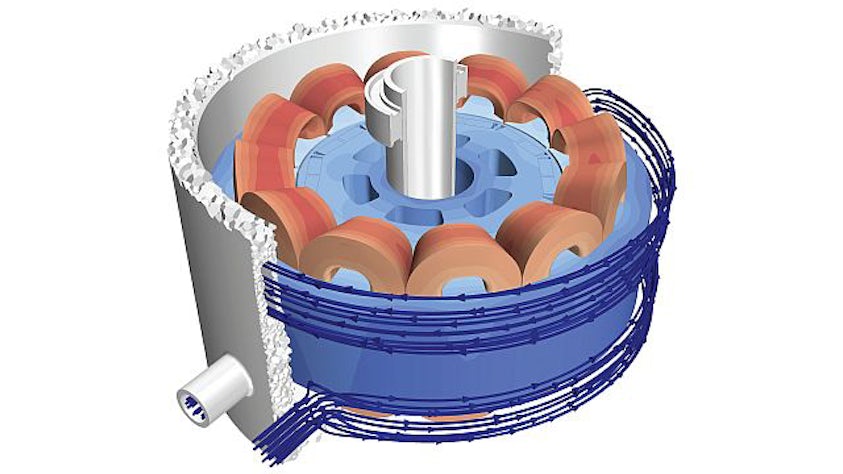

Simcenter 3D 集成了行业标准的多学科仿真求解器,所有求解器均来自集中式工程环境。Simcenter 3D 仿真求解器适用于结构、声学、结构动力学、耐久性、运动、热学、电磁学等领域,可帮助您预测各种物理场的实际性能。这种解决方案的紧密集成简化了多物理场过程,否则这些过程将难以执行。

通过仿真自动化探索各种可能性

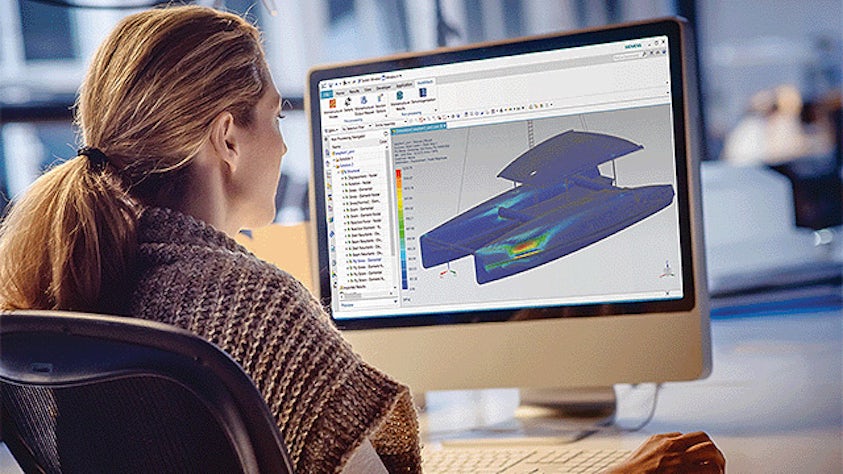

仿真的真正价值不仅在于减少所需进行的物理测试次数,还在于让您探索更多的设计选项。利用 Simcenter 3D,您能够自动修改几何体、仿真模型和求解参数,以便您可以使用集成的设计空间探索工具进行探索。您还可以将 Simcenter 3D 用作其他常用第三方求解器的预处理和后处理工具,如 ANSYS、Abaqus、MSC Nastran 和 LS-DYNA 等。这意味着您可以利用出色的 CAD 关联性、几何体编辑和全面的网格划分工具来探索您的所有仿真需求。

通过无缝数据管理进行集成

作为 Simcenter 仿真工具组合的一部分,Simcenter 3D 与涵盖 3D 仿真、1D 仿真和测试解决方案的数字主线集成。但是,仿真只是贯穿产品开发流程的更长数字主线中的一部分。Simcenter 3D 还通过与仿真数据管理相连接的无缝管理环境,将您的仿真流程与这条更长的主线联系在一起。这可以使您的仿真流程与 CAD、路线、产品诉求和制造流程等数字开发流程保持同步。

享受灵活的许可

为了使 Simcenter 3D 对仿真团队来说更加灵活,Simcenter 3D 提供了基于价值的令牌许可。您无需为每个附加模块购买单独的许可证,而是可以购买令牌包,让您和您的团队能够立即访问大多数 Simcenter 3D 模块。