零件放置和嵌套

通过完全控制零件位置和在构建空间体内自动、高效地嵌套,实现零件的高效打印。这就是 NX 推出集成工具来有效填充构建托盘的原因。无论是通过集成的 2D 和 3D 嵌套手动还是自动放置零件,NX 都能让您实现全部掌控,达到效率和质量目标。

准备是增材制造工艺的关键环节。我们的制备解决方案已集成到 NX CAD/CAM 环境中,对零件设计的更改可无缝地传递到制造设置,而无需文件转换或执行昂贵的构建设置返工。

通过完全控制零件位置和在构建空间体内自动、高效地嵌套,实现零件的高效打印。这就是 NX 推出集成工具来有效填充构建托盘的原因。无论是通过集成的 2D 和 3D 嵌套手动还是自动放置零件,NX 都能让您实现全部掌控,达到效率和质量目标。

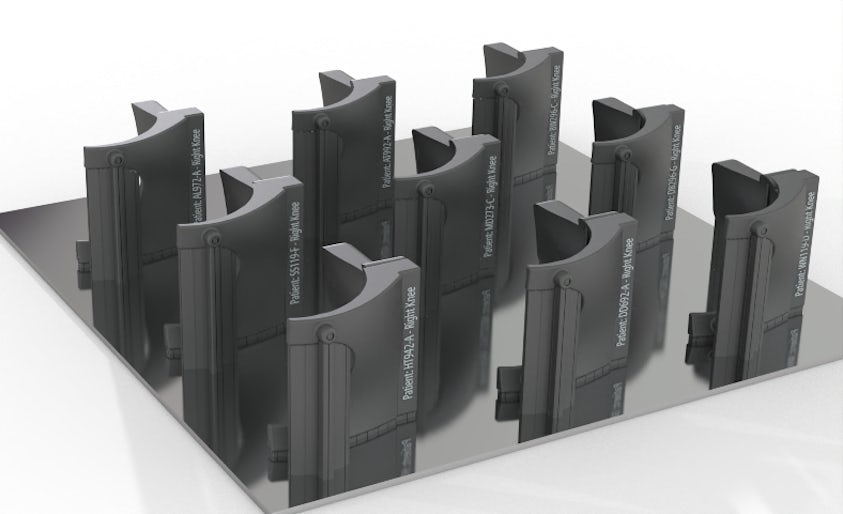

维持对生成打印标记的完全掌控,方便跟踪和认证增材制造生产。许多构建要求使用唯一的标记或编号对构建托盘中的部件进行序列化。此操作可在 NX 增材制造制备系统中完成,其中唯一标识符可通过手动、编程或电子表格界面应用。

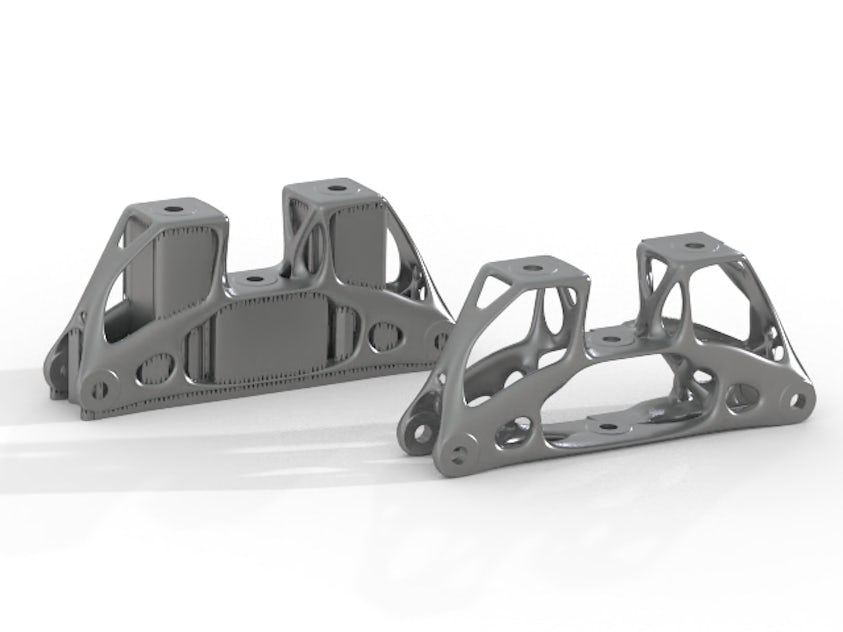

生成和构建高质量的支撑结构。对于许多增材制造技术而言,质量构建取决于质量支撑结构。NX 提供自动生成支撑结构的解决方案,还支持用户访问设计自定义支撑的完整 NX CAD 解决方案。无论您是增材制造新手还是高级用户,在打印最终产品质量至关重要的零件时,这种紧密集成都是一项巨大的优势。

公司:Unlimited Tomorrow

行业:医疗器械和制药行业

位置:纽约州纽约市, United States

Siemens 软件:NX

查看我们实用的工业增材制造设计专业解决方案。