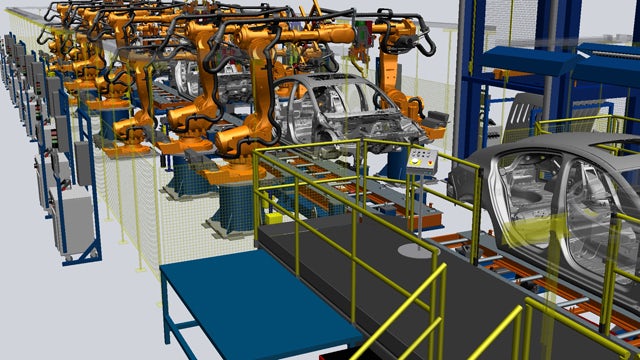

交付更好的制造工艺计划

创建和管理制造物料清单 (MBOM) 和工艺清单 (BOP),以捕获“制造内容”和“制造方式”,生成车间作业指导说明,执行详细的操作时间分析,平衡生产线等,实现工程、制造和执行团队之间的密切协作。

案例分析

博西家用电器

Tecnomatix 和 Teamcenter Easy Plan 软件助力制造商格外轻松地实现生产效率目标和业务目标。

Case Study

Leveraging an open, web-based, easy-to-use solution to standardize process planning across plants

公司:BSH Home Appliances

行业:消费品和零售行业

位置:Munich, Germany

Siemens 软件:Teamcenter, Tecnomatix

视频

Teamcenter Easy Plan 装配规划软件

Easy Plan 是一款任务导向型制造工艺规划网络解决方案。

观看此演示视频,了解更多。

探索制造工艺规划产品

采用制造工艺规划产品系列全面展开数据管理和协作,卓有成效地执行零件制造、产品装配规划和制造布局活动。