实现完整的制造质量控制

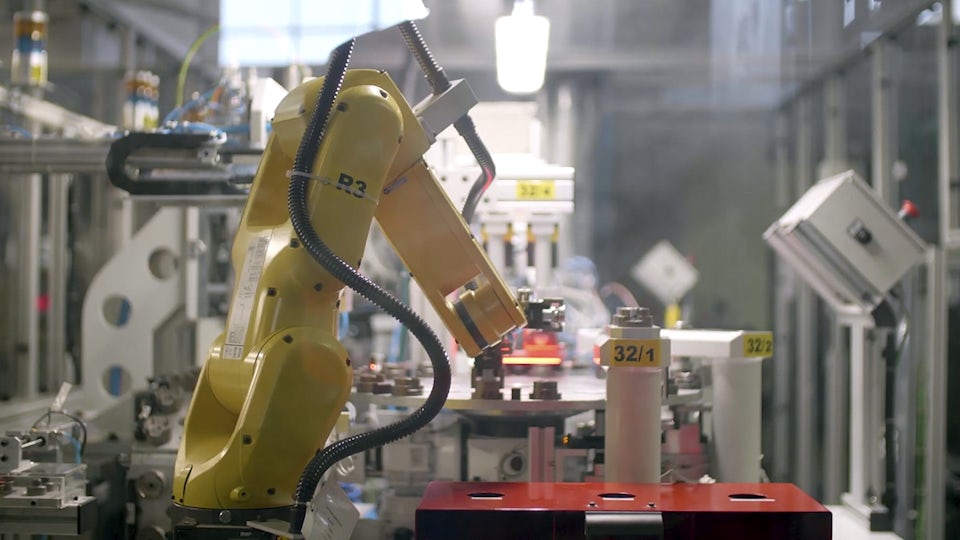

使用 Opcenter Quality Control,您可以在实际生产中将全面的数字孪生与 Teamcenter Quality 软件中的功能相结合。使用 Opcenter Quality Control 软件可以为车间的所有质量过程提供支持。

定义和执行检验计划

Opcenter Quality Control 软件可以确保产品和过程质量,能够结合贵公司整套质量相关活动的控制计划定义检验标准。Teamcenter Quality 定义控制和检验计划,然后 Opcenter Quality Control 开始收集数据、记录检验结果并控制生产过程。

管理检验工作,涵盖核心质量过程

Opcenter Quality Control 软件涵盖首次样品检验 (FSI) 和生产部件批准过程 (PPAP)。您可以定义与产品和过程相关的检验标准,将检验映射到首次取样/首件放行、采购部件/原材料、生产/装配和最终检验,包括基于数量的随机检验。

利用统计过程控制测量质量

Opcenter Quality Control 包括统计过程控制 (SPC) 和评估工具,用于测量和控制整个产品生命周期的质量。您可以创建制造质量控制图表,以图形的形式将可能影响生产作业的偶然性和系统性质量因素绘制出来,并对它们加以区分。

控制供应商质量管理

借助可用的供应商评估功能,您还可以利用供应商质量管理的关键工具。Opcenter Quality Control 软件提供了保障措施,使您的每个供应商都能达到您的标准,并成为您合适的业务合作伙伴。

简化不合格项管理

Opcenter Quality Control 可以在出现偏差时为执行的必要过程提供支持,包括在测量过程中检测公差差异。这甚至包括根据生产条件调整检验规格。Teamcenter Quality 可以检索所有信息,用于分析适当的解决问题方式。