凭借设计创新获得竞争优势

线束设计

线束设计工程师可有效捕捉设计意图,快速准确创建详尽且经过验证的线束设计。

线束产品工程

Capital 提供了自动化线束工程、验证和报告功能,可帮助线束工程师高效完成产品数据准备。

线束成本核算

Capital 线束成本建模能够帮助工程师创建全面的模型,从而确保成本生成的真实性和报价的准确性。

Capital 有助于工程师降低成本并提高质量

利用数字化数据连续性和知识产权(IP)重用,可缩短新产品导入时间。采用数字孪生技术应用自动化和模拟,可优化设计并提高产品质量。

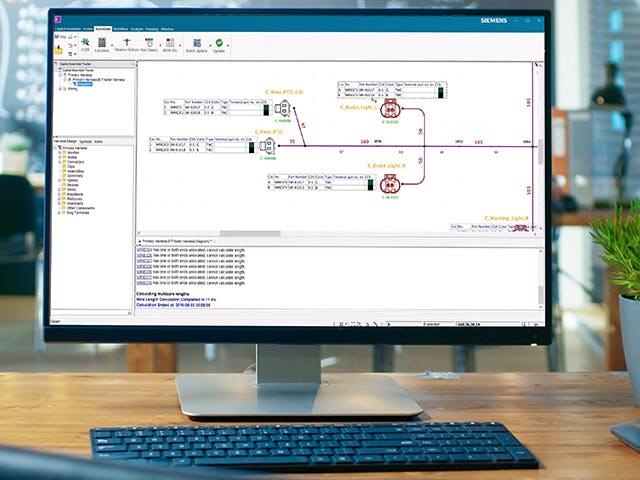

保护 IP 成本建模

至关重要的一点是,线束能够以具有竞争力和易于理解的成本进行制造。这其实是一项艰巨的挑战,因为项目时间和利润不断受到挤压,而设计内容和铜价等变量可能会迅速变化。这是一项已超出原始成本计算方法适用条件的动态任务。Capital 推出了一项理想解决方案,可自动计算成本核算,同时提供正式的框架和工艺,助力快速生成准确材料和劳动力成本核算。

Capital 提供了完全可扩展的成本建模,可保护 IP 并帮助成本计算工程师创建全面的模型。此类模型可捕获必要的细节,确保切合实际的成本生成能够创建准确的报价。数据会成为“数字主线”,支持制造工艺中的相关工具使用和重用成本计算模型。

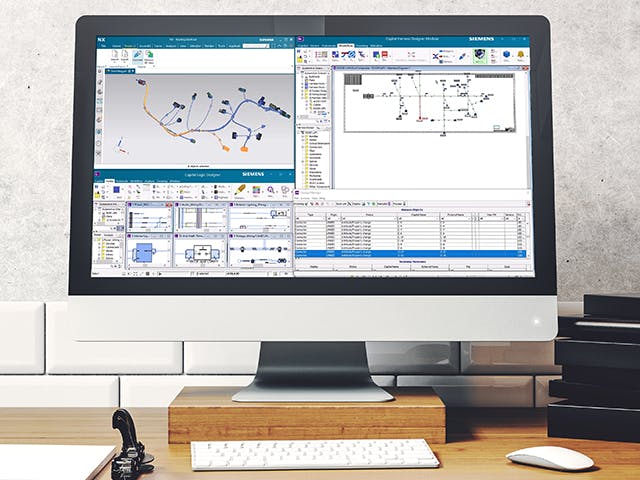

强大的图形化线束设计环境

线束设计工程师需要创建详尽的图纸,可准确捕获和描述线束的设计意图和要求。Capital 支持线束设计中涉及的所有必要活动,同时保持数字连续性。Capital 使公司能够定制工具和工艺,满足其在图形输出和报告方面的需求。

Capital 提供了强大的图形线束设计环境,可实现自动化线束设计和验证。线束设计工程师可有效地捕获和描述设计意图,创建详尽且经过验证的线束设计(图表和数据)。此外,工程师还可以定义规则和约束,促进全面的设计自动化并确保一致性。

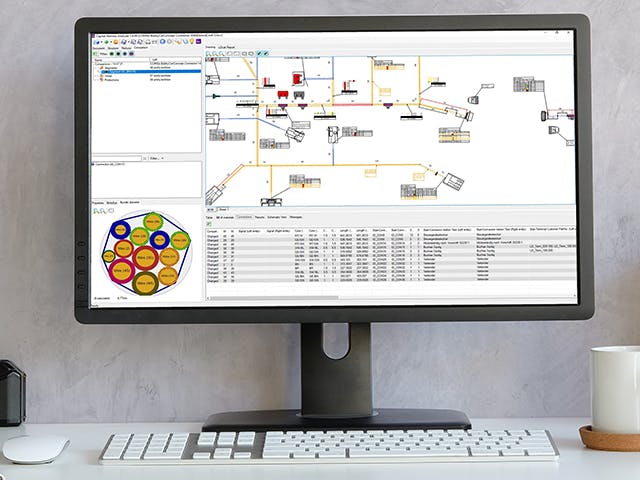

自动化线束产品工程

线束设计需要通过相关细节进行增强,例如通过成本核算和制造工程获取线束组件信息和下游消耗所需的材料数量。线束产品工程师旨在充分修饰设计数据,实现完整准确的线束定义,并提取和交付相关文档。自动化线束工程、验证和报告功能可帮助线束工程师为成本核算和制造工程任务高效准备产品数据。

组件选择例程能够自动准确地选择兼容组件,为成本核算和制造创建增强的线束数据。自动设计比较可识别不同产品修订版之间的图形和规格变化。自动化工程功能可计算描述成品的精确材料数量。

专为支持 KBL 标准构建

Capital 还提供一套领先的应用程序,用于基于 KBL 标准的布线系统设计和线束开发。

KBL 是德国汽车行业使用的数据交换标准,用于公司的主要开发部门,特别是在德国高端汽车行业。Capital 提供一套围绕该标准构建的产品,从一个逻辑系统概念到完整成套电缆,再到生产和成本计算。