连通制造以改善业务

借助 Teamcenter 制造流程规划和数据管理加快投入生产。借助即时、安全的协同来优化零件生产和装配作业。使用贯穿企业和工厂的数字主线更有效地执行所有相关活动。

在云端管理制造流程

软件即服务 (SaaS) 制造流程管理在云端可用,并由西门子专家为您管理。借助预配置的典范做法立即上手使用。通过安全的数据交换和流程可见性获取连续的制造信息。连通您的工程和制造工程师、规划人员、车间用户、合作伙伴和供应商、生产线制造商和设计公司等。

轻松规划和管理制造流程

创建和管理制造物料清单 (MBOM) 和工艺清单 (BOP) 数据以了解要制造什么以及如何制造。与西门子数字化制造解决方案相集成的 Teamcenter 简化了工程、制造和执行之间的协同。在工厂之间重用装配流程,编写作业指导并将其共享给车间,执行时间分析和生产线平衡等。

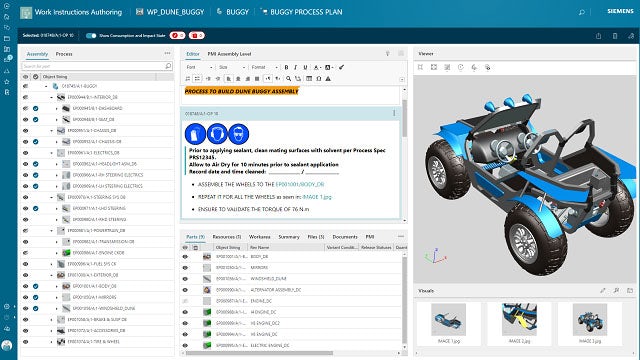

编写和共享电子作业指导

在生产中创建详尽的制造作业指导,更清楚地阐明车间中的流程步骤。提供最新信息,并使用 2D/3D 可视化工具以及增强现实 (AR) 技术清楚地演示工艺清单步骤。流程文档可通过修订管理自动更新。因此,您可以在生产之前及生产期间快速轻松地应对更改。

创建和维护工艺清单 (BOP)

在 BOP 中创建工艺和工序作为装配计划中步骤的先后顺序。将 MBOM 中的相关零件和装配分配给工序,从设备清单 (BOE) 或通过分类对象库指定所需的工具和资源。使用责任检查工具简化从产品工程到 BOP 的更改,使工程和制造保持同步。

轻松协调工程和制造 BOM

使用 Teamcenter 中的集成式产品和流程开发平台,根据设计更改快速更新装配流程计划。BOM 责任检查工具可帮助产品和制造工程师快速可视化和验证任何产品和流程更改的影响。这就避免了在生产后期发现问题并付出高昂成本。

估计操作时间并执行生产线平衡

时间管理和平衡解决方案为增值和非增值的制造流程活动提供了可见性。时间分析使用方法时间衡量 (MTM) 等时间标准,并提供了与 TiCon 的嵌入式集成。生产线平衡显示工序、工位和操作员的直观时间汇总。根据目标节拍时间优化计划,改进生产线中操作员的工作并评估替代计划。

以数字化方式管理制造资源

借助强大的搜索和检索功能,在全面的分类系统中快速找到所需内容并高效管理制造资源。制造资源库 (MRL) 提供了预加载的切削刀具数据,并可从 NX CAM 中直接访问。您可以创建刀具装配或从刀具供应商目录导入数据。

连通车间

使用单一平台连通规划和生产。直接向数控机床、坐标测量机 (CMM) 和机器人等制造设备提供正确的数据。在各职能领域传达完整的制造流程规划。明确产品制造的内容、方式和地点。确保所有利益相关者都知道需要哪些资源。

Next-generation collaboration with Teamcenter Share

Optimize your production and manufacturing processes with Teamcenter Share, a cloud-based collaboration solution with a seamless connection to Teamcenter Easy Plan software. Extend the reach of manufacturing planning-related data and processes beyond your internal teams to work smarter and accelerate innovation.