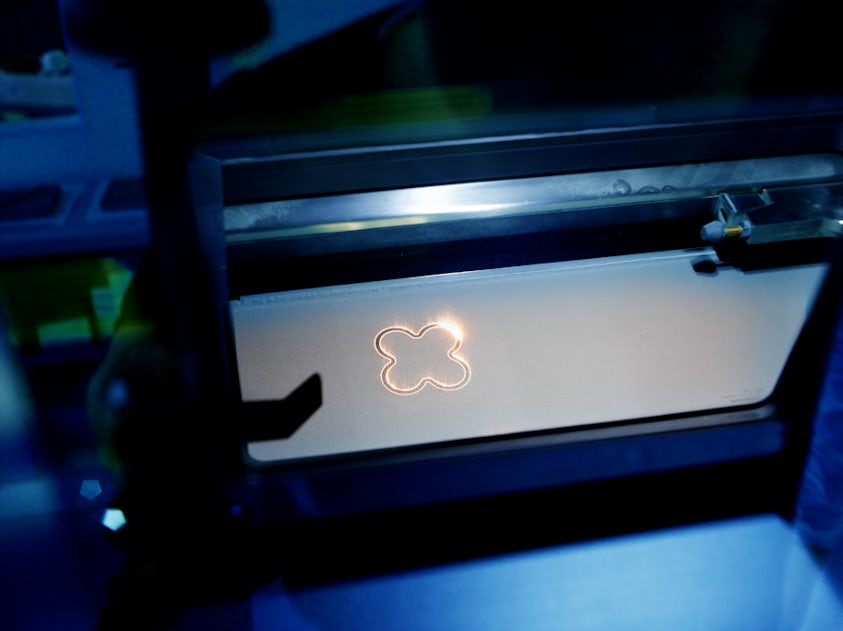

SLS是一种用于 增材制造(AM)的粉末床熔融技术。它通过使用激光选择性地加热粉末颗粒来创建 3D 对象,使它们融合并成为固体结构。

在烧结过程中,材料被加热到足以开始在颗粒之间开始原子扩散——使它们结合而没有实际熔化。SLS 机器使用脉冲激光以足够的精度烧结粉末颗粒,以3D 打印具有高度复杂几何形状的塑料、金属、陶瓷和玻璃零件。

由于选择性激光烧结可以直接从 CAD 数据轻松创建复杂的形状,并且与各种材料兼容,因此选择性激光烧结是一种用于制造原型和最终用途零件的极其通用的技术。

相关产品:NX AM Fixed Plane | NX AM Multi-Axis | NX AM Build Optimizer