Aerospace supplier cuts time and cost of delivering composite parts for the Joint Strike Fighter

Use of Fibersim helps Quickstep Technology become a major player in aerospace

Quickstep Technology

Quickstep Holdings Limited (ASX: QHL) is an Australian-listed company which, through its subsidiary company Quickstep Technology Pty Ltd, has investments in advanced composite manufacturing facilities in Australia and advanced composite manufac-turing technologies for the global market.

https://www.quickstep.com.au/- Headquarters:

- North Coogee, Australia

- Products:

- Fibersim

- Industry Sector:

- Aerospace & defense

Working with composites is extremely time-consuming and tedious. By adopting Fibersim, we are automating nonvalue-added tasks to achieve significant productivity gains, improving overall part quality and repeatability, and increasing our throughput. Vistagy (which was acquired by Siemens Digital Industries Software) was a pioneer in composites engineering for aerospace and that experi-ence is reflected in Fibersim’s capabilities.

Quickstep

First part order delivered a month ahead of schedule

Quickstep Technology Pty Ltd (Quickstep) is taking aim at becoming a major player in the Australian aerospace industry, and the Fibersim™ portfolio of software for com-posites engineering from Siemens Digital Industries Software is playing a key role in that initiative.

In 2009, Quickstep signed a more than $700 million Memorandum of Understanding with Lockheed Martin and Northrop Grumman to build key components for the next generation of the Joint Strike Fighter (JSF), the F-35 Lightning II. Quickstep is currently working with Northrop Grumman.

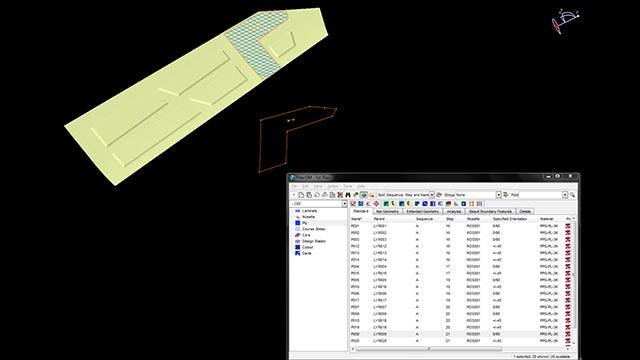

The company chose to use Fibersim to manufacture the largest and most complex composite parts they have produced to date on the JSF, including lower side skins, maintenance access panels, the F2 fuel tank cover and the lower skin and in-board weapons bay doors. The software is being used to simulate material draping, define flat patterns and generate data to drive its laser projection system.

Quickstep received its first purchase order in July 2011, covering production of small-to-medium-size JSF components of intermediate complexity over an initial 12 month period, and shipped its first production part, a destruction test panel, more than a month ahead of schedule in October 2011.

Enhancing competitiveness

It is anticipated that over the next quarter century, the nine partner nations that are financing the F-35 (United States, United Kingdom, Italy, Netherlands, Canada, Turkey, Australia, Norway, and Denmark) will order 3,100 airplanes. Quickstep will potentially manufacture more than 36,000 parts as part of the international supply chain that will produce composite sub assemblies.

“Fibersim enhances our competitiveness by enabling us to qualify as an approved sup-plier,” says Michael Schramko, Quickstep chief operating officer. “Without it, we wouldn’t be able to keep up with the pro-duction schedule for a program such as the Joint Strike Fighter.

“Working with composites is extremely time-consuming and tedious. By adopting Fibersim, we are automating nonvalue-added tasks to achieve significant productivity gains, improving overall part quality and repeatability and increasing our throughput. Vistagy (which was acquired by Siemens Digital Industries Software in December 2011) was a pioneer in composites engineering for aerospace, and that experience is reflected in the capabilities of Fibersim.”

Quickstep offers composite materials engineering, advanced composite manufacturing and plant solutions for manufacturing advanced composite components. The company was founded in 2001 to commercialize the “Quickstep Process,” an innovative fluid-based curing technology that significantly reduces the cost and time for producing composites compared with conventional autoclave curing techniques.

The manual process that Quickstep used previously only worked for parts with simpler geometry. For the more complex parts – such as those used for the JSF – a more sophisticated methodology was required to accurately define, manage, drape and output ply data.

Continuing the tradition

Quickstep’s use of Fibersim in connection with the JSF continues a long history of support from Vistagy (now Siemens) on this critical defense program. For more than a decade, many of the leading aero-space companies in the world – including Lockheed Martin, Northrop Grumman and BAE Systems – have used Fibersim to design and manufacture a variety of composite parts for the JSF; from wing skins and intake fairings to fuselage skins and spars.

In fact, Fibersim was also used by Boeing on the X-32, its JSF demonstrator. The use of Fibersim for the JSF program began in 1997 – when the earth was flat by composite standards – when Lockheed Martin engineers selected the advanced composites engineering technology to help them define ply geometries for two demonstra-tor aircraft.

The first part Lockheed Martin engineers used Fibersim on was the auxiliary inlet duct. This part presented a difficult design challenge because its complex contours can distort the composite plies, shifting the fabric orientation to an extent that weakens the part. In severe cases, the plies bridge over areas where the complexity of the curvature prevents them from conforming precisely to the surface, and in other areas, they will bunch up and create wrinkles that cause unacceptable structural weakening.

Ultimately, the use of Fibersim cut engineering time from 300 to 150 hours and manufacturing time from 450 to 200 hours on the inlet duct. Based on this early success, Lockheed Martin engineers decided to use Fibersim to produce both JSF demonstrators. They produced over 80 parts with Fibersim and saved an average of 20 percent per part. Fibersim has been used for composites work on the JSF program ever since.

Exploiting openness

Engineers who design and manufacture composite parts face the time-consuming and difficult process of exporting flat patterns to nesting software, automated cutting systems and laser projection machines. Without an automated way of exporting flat patterns from the computer-aided design (CAD) model, engineers often find that their flat patterns are inaccurate or that they have difficulty laying them up properly.

One of the key factors influencing Quickstep’s selection of Fibersim was its support of an open strategy. Fibersim is integrated with nearly every commercial laser projection system and cutting machine, so customers can use the system that best fits their process and environment. In the case of Quickstep, engineers were able to seamlessly use data from Fibersim to drive their laser projection system and cutting machine.

By using the Flat Pattern module in the Fibersim portfolio, Quickstep was able to automatically generate flat pattern data files for export from their Catia® software directly to their nesting system. The software maintained file integrity by including attributes such as ply name, sequence, material specification and orientation, and eliminated the need for manual sorting or manipulation of drawings and patterns. It also allowed for filleted corners to create optimized flat patterns for cutting. As a result, the use of Fibersim increased engineering efficiency and manufacturing productivity, while achieving more accurate flat patterns and less material waste.

By using the Laser Projection module in the Fibersim portfolio, Quickstep automatically generated laser data files from the 3D CAD model to drive its laser projection machine. Quickstep uses a laser projection system to reduce errors and shorten the layup time for its composite parts by displaying ply outlines directly on the layup tool. These laser outlines aid engineers in properly locating and orienting the plies during the layup process.

“Using Fibersim has also proven to be quite beneficial during the bid process as it quickly and accurately nests parts, so we can assess material usage for determining costs. It’s also easy to use and understand, which means our engineers can get up to speed on it quite quickly, helping to move the development process forward.”

That’s important when you may be called upon to turn out more than 36,000 parts over the next quarter century.

Fibersim is able to easily and accurately export our flat pattern and laser projection system data from Catia to the software that programs our manufacturing machines. This is invaluable to the success of our business. We have found the ply shapes that we have produced with Fibersim to be accurate and do not require manual alteration.

Quickstep