Major automotive supplier employs Simcenter Amesim to design innovative powertrain system for off-highway vehicles

Siemens Digital Industries Software technology helps Dana develop a powertrain system which delivers between 20 to 40 percent fuel savings and reduced operating costs

Dana

Dana partners with virtually every major vehicle and engine manufacturer worldwide as a leading supplier of drivetrain, sealing and thermal technologies to the global automotive, commercial-vehicle and offhighway markets. Founded in 1904, Dana employs thousands of people across five continents. Dana Holding Corporation’s OffHighway Driveline Technologies include research and development, manufacturing and assembly operations in Belgium, Brazil, China, Hungary, India, Italy, Mexico, the U.K. and the U.S. The company designs, manufactures, assembles, and markets Spicer axles and transaxles, driveshafts and end-fittings, transmissions, torque converters, electronic controls and brakes. It also provides genuine replacement parts and service. Dana serves more than 1,000 vehicle assembly and manufacturing facilities in thirty countries.

http://www.dana.com/- Headquarters:

- Maumee, Ohio, United States

- Products:

- Simcenter Products, Simcenter Amesim

- Industry Sector:

- Heavy equipment

We can definitely say that Simcenter Amesim reduced a considerable part of the development time by a factor of 5, and then we are not even talking about cost.

Dana

Making the delivery of high power for a downsized engine a reality

Construction and material-handling vehicles have to carry heavy loads from point A to point B, requiring frequent and intense bursts of acceleration, deceleration, lifting and lowering. On the other hand, environmental regulations push for lower emissions, while the market wants lower operating costs. Combining all these design requirements is a daily challenge for off-highway vehicle manufacturers. In an attempt to downsize engines while still guaranteeing maximum power when it’s needed, original equipment manufacturers (OEMs) and suppliers are constantly looking for next-generation powertrain architectures that deliver maximum performance with a minimum amount of fuel.

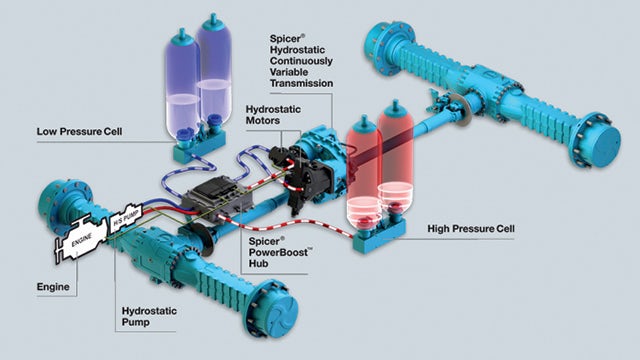

For this purpose, Dana, the world-leading supplier of driveline, sealing and thermalmanagement technologies, developed the Spicer® PowerBoost Hydraulic-Hybrid System™. This integrated powertrain concept for the off-highway market captures kinetic energy, otherwise wasted throughout the drivetrain, and uses this recuperated energy to help power the vehicle when in operation. An advanced energy management system evaluates the levels of power needed in the entire vehicle system, predicts operating demands, and determines the most efficient means of operation. The system captures energy from the powertrain during low-power operation and recuperated from braking and working cycles as hydrostatic energy in an accumulator. This storage is then released when additional power is required, for example when accelerating from rest, lifting a load, or driving into a pile. Prototype tests on a front-end loader and a telescopic boom handler promised from 20 percent up to 40 percent fuel savings, reducing operating costs and providing scope for a downsized engine.

Powerful simulation tools that model all components together

“While developing this groundbreaking system, Dana Advanced Engineering, a cross-business unit of specialists within Dana Holding, extensively employed simulation by implementing model-based systems engineering approaches,” says Dr. Lorenzo Serrao, senior system engineer at Dana. Simcenter Amesim software from digital industries (DI) specialist Siemens Digital Industries Software was the crucial tool to model all components together, including mechanical elements, hydraulic machines, control circuit and accumulators. “The simulation model was essential in all phases of the development cycle, and a necessary complement to the test lab, where we have a prototype of the isolated system in an experimental setup, and the vehicle lab, where we have integrated the prototype in a front-end loader,” adds Serrao. “We used the model during the concept phase to evaluate design alternatives, to effectively integrate subsystems within the vehicle, for controls development and finally to test control functionality and assess performance through simulation prior to physical testing.”

Dana engineers are especially satisfied with the ease-of-use of Simcenter Amesim and with its powerful solver capabilities. The models run extremely fast and the presence of extensive libraries allows them to prepare complex multi-domain models with physical and geometrical component parameterization much faster than using traditional methods based on coding the differential equations. The control strategy can be easily included thanks to seamless co-simulation using the MATLAB® environment and Simulink® environment, both from The MathWorks Inc. With standard libraries and parameters, Dana builds models that are more than 90 percent correct. “We have not at all yet reached the limits of Simcenter Amesim. We will continue using the standard libraries. Only in the very last steps we will use customized ones,” says Serrao.

Thanks to the use of Simcenter Amesim, Dana saved both time and money developing the PowerBoost system. System simulation reduced the need for physical testing, and the ability to debug system integration issues and controls in simulation avoided damage in the system hardware. “Thanks to our modeling in Simcenter Amesim, we could reduce the number of loops,” says Serrao. “The entire development project took three years. The first year was mainly about simulation. Then the second year we started to work more and more on the vehicle. If we want to evaluate a modification, it only takes us about a day on the simulation model, whereas on the test bench or on the real vehicle, this takes us one or two weeks. We can definitely say that using Simcenter Amesim reduced a considerable part of the development time by a factor of five, and then we are not even talking about cost.”

Simcenter Amesim, a go-to tool in Dana’s future

Dana’s advanced engineering group further integrated Simcenter Amesim into the development processes, and appreciates the value the solution has provided. Given increasing market and legislative pressure on more efficiency and less fuel consumption, the importance of Simcenter Amesim is expected to increase even more in future projects. Dana engineers realize that if they want to keep ahead of the competition, they will need to continue increasing product efficiency and production processes and creating higher product value in terms of integration and variety. “Solutions based on increased system integration, such as powertrain hybridization, are definitely the way forward for optimized vehicle efficiency,” notes Serrao. “Model-based systems engineering has definitely contributed a lot to the success of this and will continue doing so even more so in the future.”

“We have not at all yet reached the limits of Simcenter Amesim. We will still continue using the standard libraries. Only in the very last steps will we use customized ones.

Dana