Robot simulation boosts profitability by 30 percent

Tecnomatix helps company realize a 60 percent decrease in the time needed to design and install robotic systems

AKE Robotics

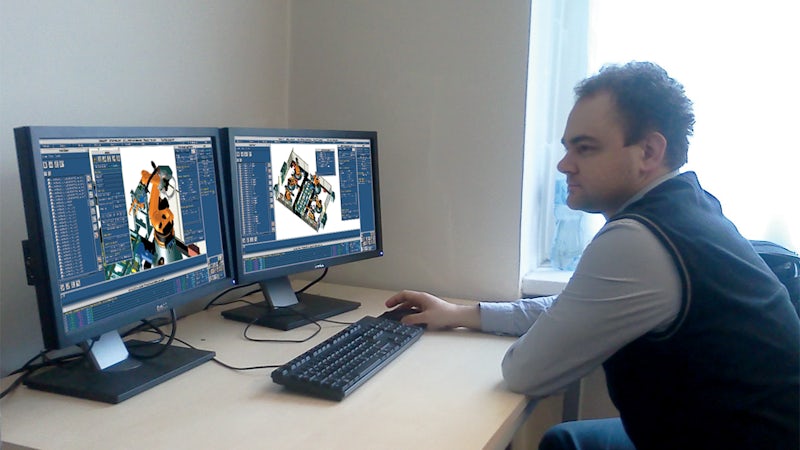

AKE Robotics configures and programs all types of industrial robots.

http://www.ake-robotics.pl- Headquarters:

- Bielsko-Biała, Poland

- Products:

- Tecnomatix

- Industry Sector:

- Industrial machinery

Thanks to the use of Robcad software, we have increased profitability by 30 percent and eliminated 90+ percent of project-related errors.

AKE Robotics

Precision absolutely required

AKE Robotics Sp. z o.o. (AKE Robotics) is a subsidiary of the German enterprise AKE Systemtechnik GmbH. The parent company designs and builds everything from transport systems to robotic manufacturing cells. AKE Robotics, located in Poland, configures and programs all types of industrial robots for applications in manufacturing, assembly and logistics. By incorporating the most up-to-date technology in the field of industrial robotics, AKE Robotics meets the demands of exacting customers, including Volkswagen, Volvo Gent, Mercedes, Audi and Seat.

Supplying robots to the global market requires the highest quality standards. The configuration of crucial production environments has a decisive influence on the high level of responsibility for each realization. In many situations, AKE Robotics’ work is constrained by time and space limitations, but the company must still deliver reliable, essentially flawless robot operations. Inaccurate installations result in costly production downtimes and require considerable expenditures to correct. Also, when there are errors, repair work must be done at the customer’s site, significantly reducing the profitability of that project.

Compatibility key in software selection

To improve quality and minimize risks, AKE Robotics decided to implement a robot programming and simulation solution. One of the features the company searched for in this type of software was compatibility with leading computer-aided design (CAD) systems. In addition to making its own designers’ work easier (if customers’ CAD data could be imported), compatibility with other systems would also make it easier for the company to expand into new markets.

The openness and strong reputation of Robcad™ software, part of the Tecnomatix® software portfolio from Siemens Digital Industries Software, made it the right choice for AKE Robotics. “The main reasons we went with Robcad were because it offered us the possibility of working with prestigious automakers and because it is compatible with our parent company in Germany, which uses Robcad as well,” says Bartłomiej Siuda, managing director at AKE Robotics. “It also lets us take on smaller projects, which were previously unprofitable for us.” He notes, “All of the company’s designers had already used Robcad at previous jobs, so the software was implemented in a flash.”

Efficiency and optimization reflected in the numbers

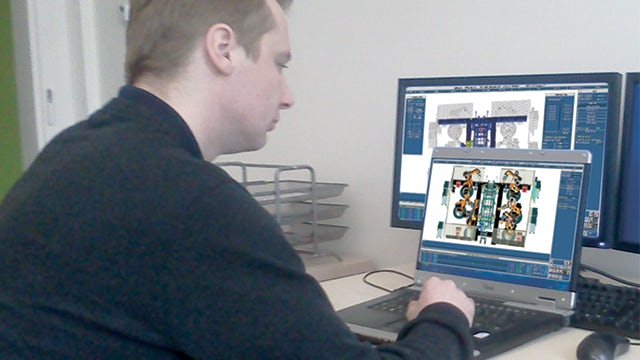

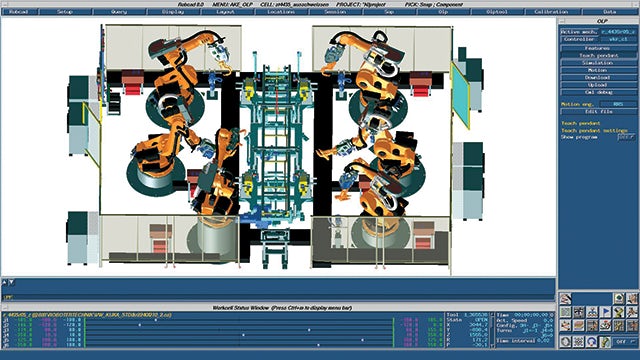

The use of Robcad has dramatically improved employee productivity at AKE Robotics. The designers no longer waste time redesigning elements of a robot system that already exists. Also, with Robcad they can create systems that don’t require additional changes as they are installed. In the past, when assembly and process-related errors occurred, it was necessary for employees to spend long periods at customer sites across Europe. Not only did this reduce the profitability of a project, it prevented those employees from taking on new tasks. Robcad allows robot programming to be done offline (and not at the customer’s site); the software’s simulation functionality literally reduces errors found as the robots are being installed.

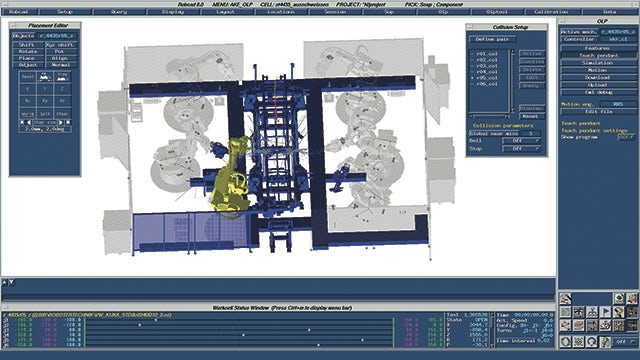

“Performing work at the customer’s facility is very costly,” says Siuda. “Robcad lets us work remotely in the preliminary stages of a project, and also lets us detect and eliminate collisions early on.” This has reduced the project travel costs by 25 percent, saving 120,000 zlotys (approximately $44,000 US dollars) per year. Overall, Siuda estimates that the improved productivity made possible by Robcad has increased the profitability of every project by 30 percent.

Another important benefit resulting from the use of Robcad is a 60 percent reduction in the time needed to design and install a new robotic system. This comes mainly from using simulation to detect errors early in the development cycle. “The ability to perform a full simulation eliminates the occurrence of construction errors and tooling faults, as well as errors in the elements of installation,” explains Siuda. “Thanks to design accuracy as well as the tool for collision detection, we have eliminated more than 90+ percent of the situations in which we previously noted discrepancies. Now we are able to eliminate them even before the delivery of equipment to the customer’s site.”

Siemens Digital Industries Software’s offline robot programming solution played an important role in a spectacular success at AKE Robotics. Siuda notes, “Thanks to Robcad, we established a permanent relationship with Volkswagen, which also uses Siemens’ software.”

No longer just another subcontractor

“Robcad software has allowed us to move to another level,” says Siuda. “Nowadays, unlike many others, we are a partner that participates in the development of the project. We are not an ordinary subcontractor anymore.”