The current stringent emissions, noise, and safety standards for automotive OEMs and suppliers in a highly competitive marketplace require the development of innovative products, with significant growth of electronic systems realizing smart functions.

In this context, engine actuators such as fuel systems, valvetrains, engine mechanical systems and airpath & exhaust systems need to be designed by optimizing multiple vehicle attributes as fuel economy, emissions, driving performances, NVH and drivability. That is the focus of our webinar:

- First, Francesca Furno introduces typical engineering activities from components design optimization to hardware and software integration at vehicle level regarding engine actuators.

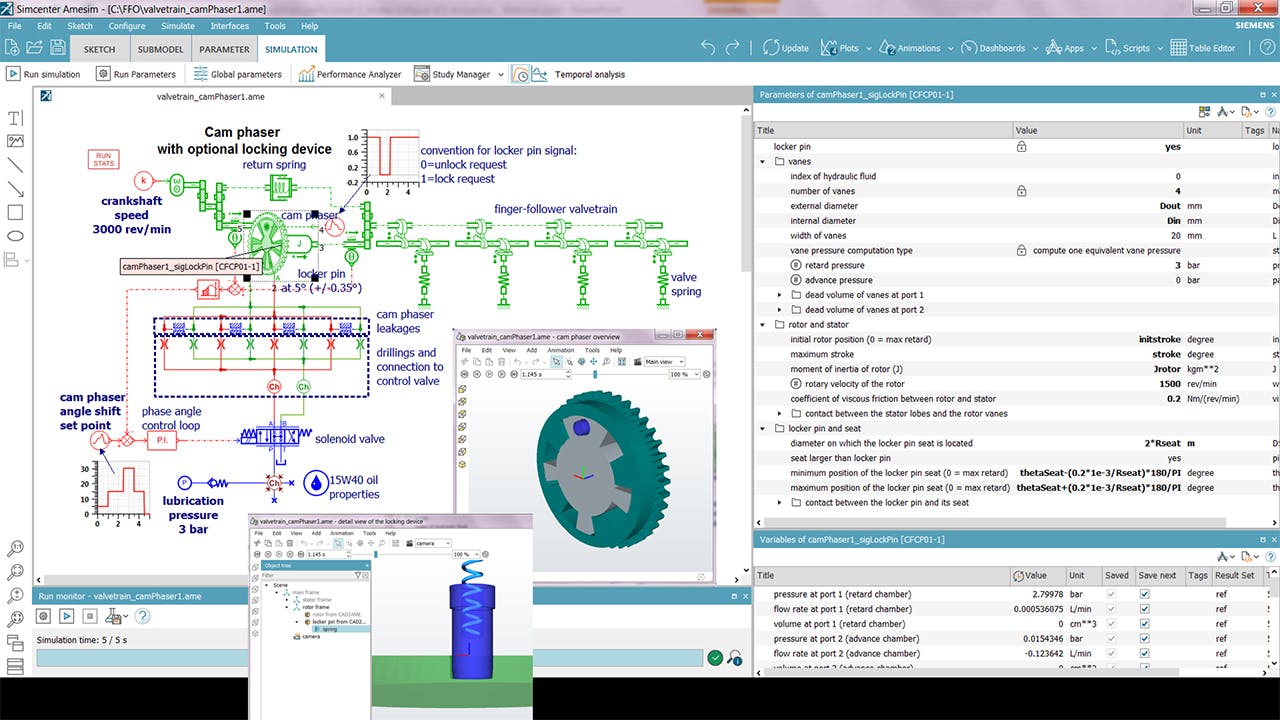

- Second, Masashi Hayashi from Denso explains how he predicts Hydraulic Variable Camshaft Timing (VCT) performance in various conditions, precisely controlling the fuel and air composition into the combustion engine, to improve engine performance.

More on Masashi Hayashi: Digital engineering expert for powertrain components design and simulation. Hayashi-san joined Denso as parts engineer for valve train system in 1993. Then he worked as simulations engineer for Hydraulic VCT design from 2000 to 2017, before becoming digital engineering expert for powertrain components.

More on Ph.D Francesca Furno: Francesca received her MSc. Degree in Mechanical Engineering and PhD. Degree in Energetic Systems from the Politecnico di Torino – Italy. Her main competence domain is hydraulic components and systems simulation. Following few years of working experience in Italy, she joined the former LMS Imagine Division on 2007 as project engineer; currently she is working at Siemens Digital Industries Software as Business Developer focusing on Fluid Applications.