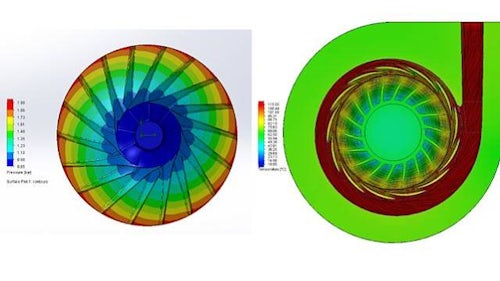

Численное моделирование аэродинамики в безмасляном воздушном турбокомпрессоре

Чтобы сохранять конкурентоспособность в компрессорной отрасли и создавать надежное оборудование по максимально низкой стоимости, компании должны использовать новые технологии. Разработать высокоэффективные воздушные турбокомпрессоры сложно без понимания того, как принимаемые решения влияют на характеристики конечного изделия.

Загрузите статью, чтобы узнать, как Tamturbo, производитель воздушных компрессоров из Финляндии, использует вычислительную гидрогазодинамику (CFD) на всех этапах разработки, включая ранние, чтобы улучшить их конструкцию и снизить стоимость.

Tamturbo преодолела ограничение традиционных кодов CFD — очень мелкая сетка рядом со стенками в расчетной области с помощью метода «двухмасштабных функций стенки». Для учета вращения импеллеров использовалась специальная вращающаяся модель скольжения, которая позволяет прогнозировать характеристики любого типа турбокомпрессоров с лучшей точностью.

Загрузите статью, чтобы узнать больше об использовании CFD на ранних этапах разработки для прогнозирования характеристик компрессоров непосредственно в CAD-среде.