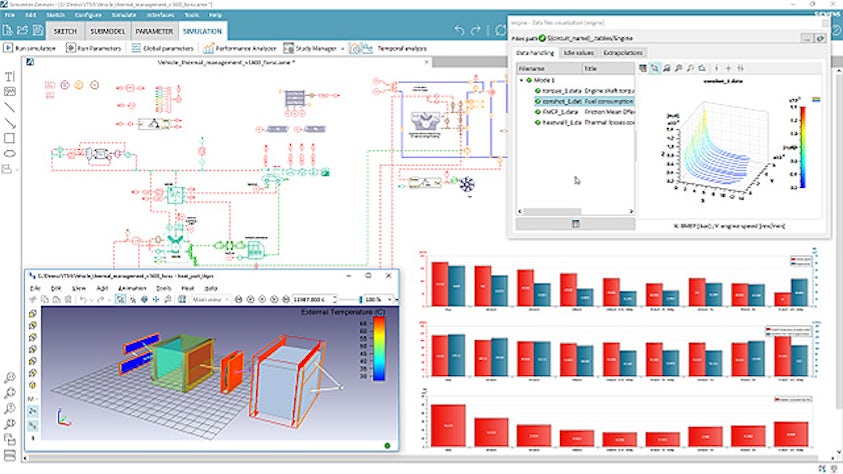

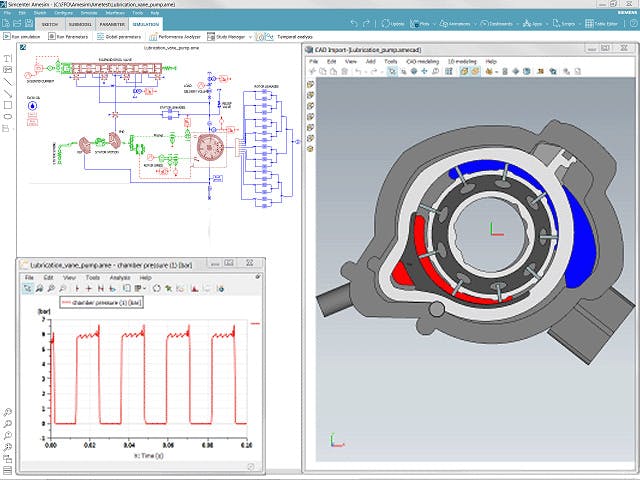

Keeping the temperature of components within the optimal operating range, evacuating excess heat or reusing it to improve performance and efficiency is an inherent challenge for today’s complex systems. To help you address thermal integration issues, Simcenter offers you a comprehensive set of solutions that cover the whole design cycle from predesign stage to final validation.

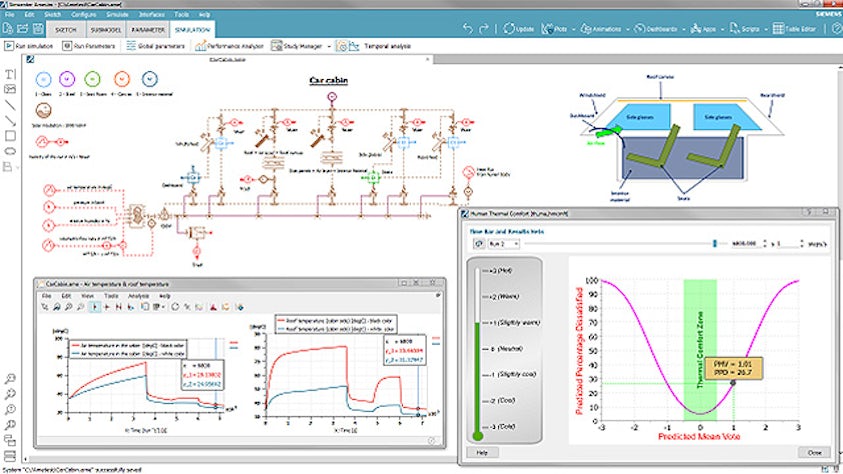

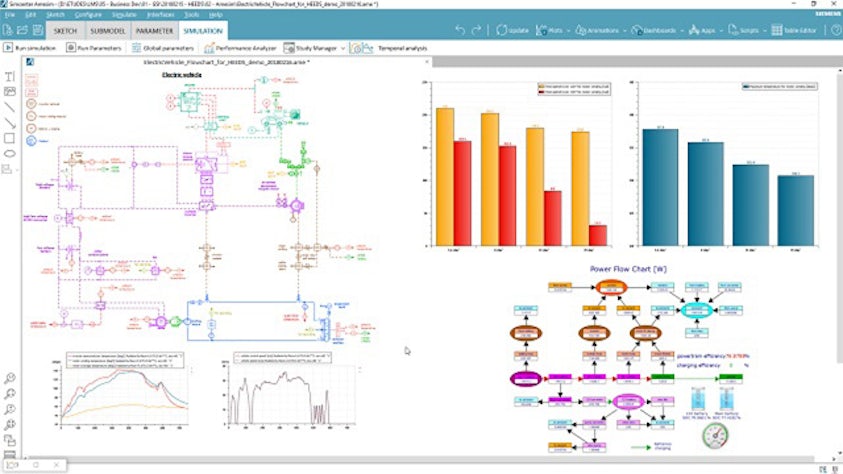

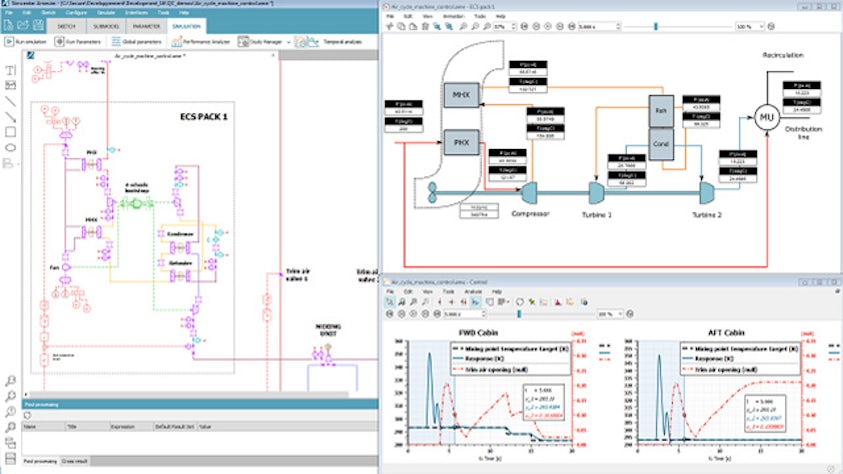

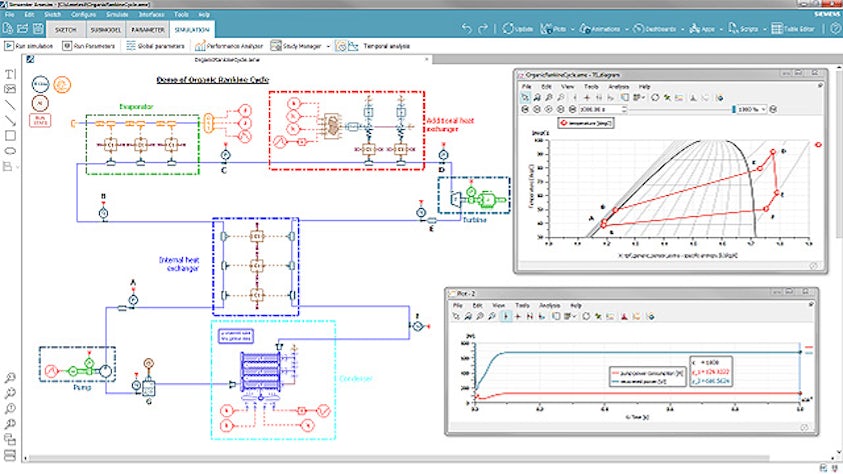

Simcenter helps maximize thermal performance such as comfort in cars, planes or rooms, while optimizing energy efficiency. You can use the software to represent the real operating environment of your system, including interactions with surroundings when designing and validating your temperature control strategies. Additionally, Simcenter enables you to study the integration of energy recovery systems and their impact on performance and energy consumption. You can also benefit from the advanced post-processing features to graphically visualize energy flows in your system.

Race to the clouds: Battery thermal behavior simulation of a Tesla Model 3

Simulate the Pikes Peak Hill Climb with a Tesla Model 3 and understand the battery thermal behavior.