How robotics can modernize your production

Robotic technology provides high automation and flexibility that can dramatically improve efficiency on the shop floor.

Discover the powerful features of advanced robotic automation:

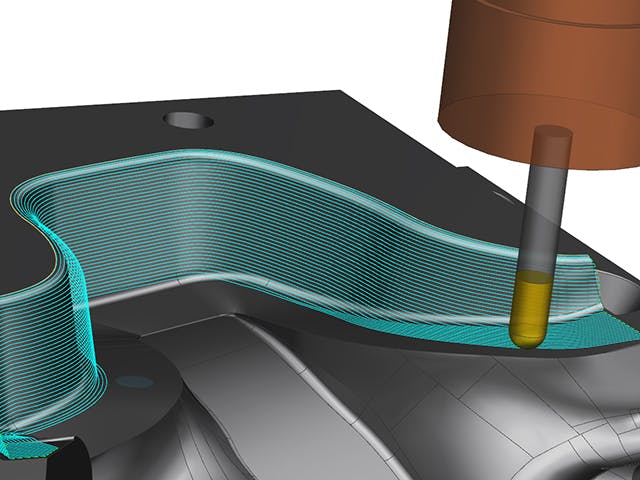

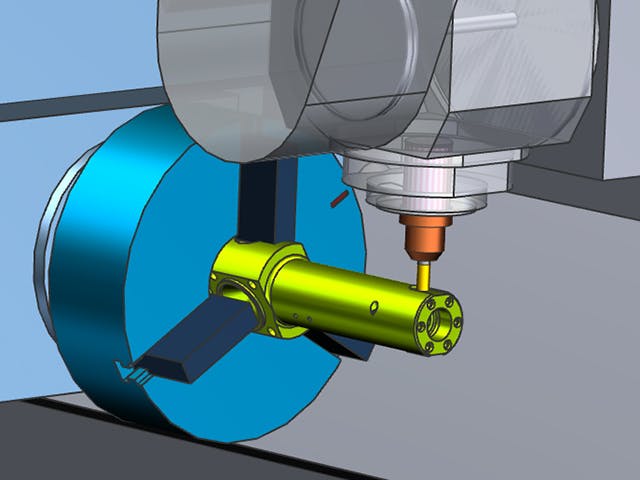

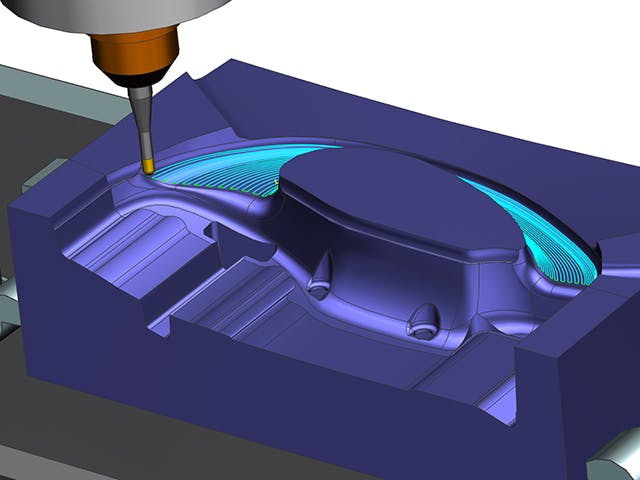

Expand capabilities with robotic machining

Program robots to machine large parts, expanding the machining work envelope. Robots help you automate machining tasks typically performed manually.

Use NX CAM to program and simulate robots to perform precise multi-axis machining, including:

- Trimming

- De-burring

- Grinding

- Polishing

Advanced robotics helps you reduce production costs and improve machining accuracy.

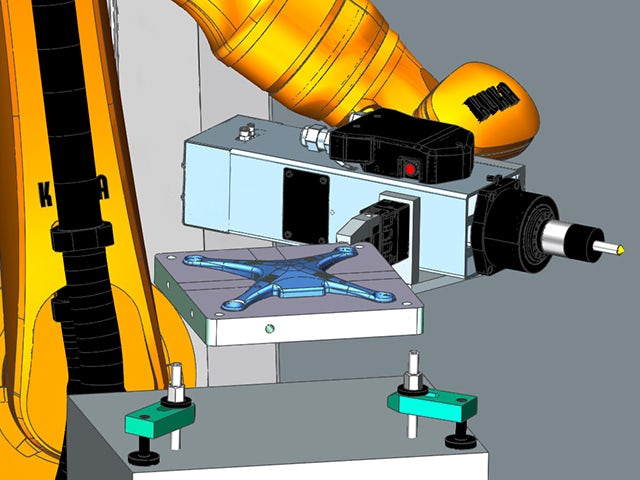

Program robots for pick-and-place operations

Further automate your part manufacturing operation by using robots to perform pick-and-place tasks, including machine tending and tool loading.

These tasks allow extended unattended machining that can maximize your production capacity.

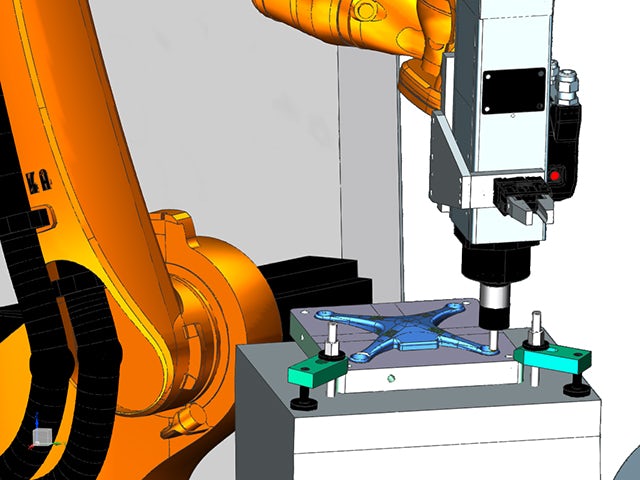

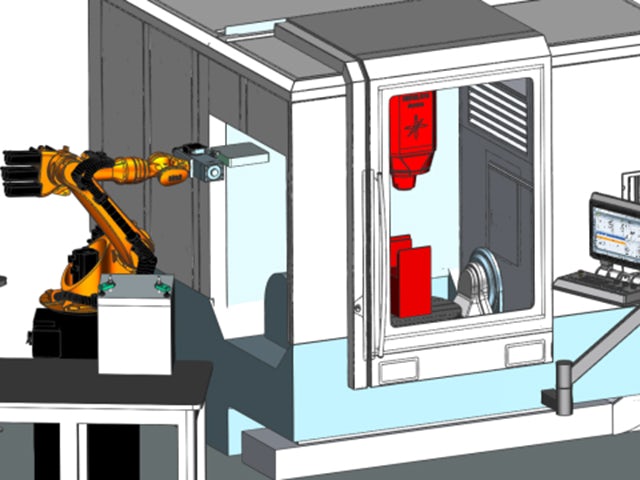

Automate complete production workcells using robots

Boost shop floor productivity with automated workcells. Modernize production with advanced robotics and CNC technology to reduce cost and lead time.

Use NX to program fully automated workcells to perform all the necessary operations, including:

- Robotic machine tending

- CNC machining

- Robotic machining

Explore NX for manufacturing products

Get more details about our wide range of solutions for your specific part manufacturing needs.

Siemens Teamcenter Share

Optimize your entire production process with Teamcenter Share, a cloud-based collaboration solution, which seamlessly connects to NX CAM software. Securely communicate and share information with internal and external stakeholders in the cloud.

Connect design, manufacturing and shop floor teams to run more flexible and efficient production.