Hydraulic component manufacturer uses Simcenter Amesim to solve dynamic instability

Fluid-System cuts prototype adjustment time by 50 percent with the help of Siemens Digital Industries Software

Fluid-System

Fluid-System is part of the Fluidesign organization, as is its partner company, Designtronic. Founded in 1984, Fluidesign is a designer and manufacturer of hydraulic, electronic and mechatronic assemblies. Fluid-System produces hydraulic components and Designtronic makes electronic assemblies.

http://www.fluidesign.eu- Headquarters:

- Lorette, France

- Products:

- Simcenter Products, Simcenter Amesim

- Industry Sector:

- Aerospace & defense, Automotive & transportation

Simcenter Amesim stood out amongst other competitors. The solution is really robust, technically precise and the various libraries are comprehensive.

Fluid-System

Shortening time-to-market

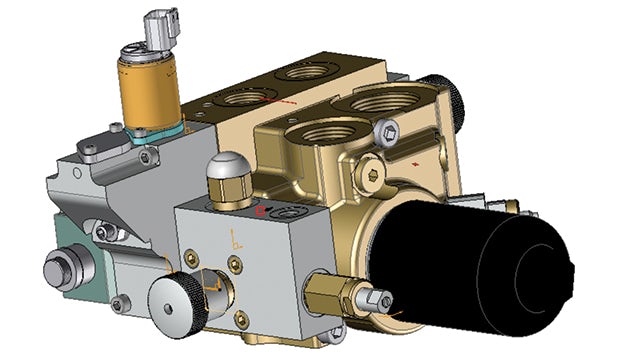

Part of a two-company design partnership that operates under the parent organization Fluidesign, Fluid-System is one of those innovative companies that fly under the radar. Its talented team of researchers works diligently to create hydraulic components for distribution, pressure and flow regulation. More often than not, the final Fluid-System components must be seamlessly integrated with the control units of embedded electronics found in modernday agricultural, maintenance, industrial, marine and railway vehicles.

That is why the team at Fluid-System works closely with its partner company, Designtronic, which specializes in embedded electronic device design. They market their work under the name Fluidesign. And, like any original equipment manufacturer (OEM) supplier these days, many of Fluidesign’s customers expect nothing less than perfection when it comes to product performance. So when members of the Fluid-System research and development (R&D) department ran into some dynamic stability issues on the test bench, they decided that they needed to conduct several studies on the flow regulation. Of course, they could do this the old-fashioned way with prototyping and research procedures, but the team just didn’t have the time to do that. They needed to find a tool that would enable them to work quickly and substantially shorten time-to-market.

That tool turned out to be Simcenter Amesim™ software, part of the Simcenter™ portfolio from Siemens Digital Industries Software.

Determining the right tradeoffs

“Simcenter Amesim stood out amongst other competitors,” says Xavier Tardy, chief executive officer (CEO) of FluidSystem. “The solution is really robust, technically precise and the various libraries are comprehensive.”

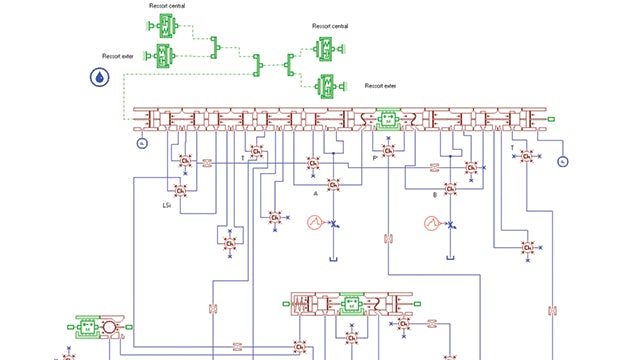

When the R&D team members put the software through its paces, they were immediately reassured that the CEO made the right choice. Early in the development process, the 1D model enabled the researchers to try out a variety of technical choices. Another key feature was the capability of the software to pre-empt flow regulation and stability. From a practical design standpoint, this meant that Fluidesign could determine the right tradeoff between stability and performance parameters for its pressure relief valves, all during the concept stage without any back and forth between development teams.

“Another plus for Simcenter Amesim is that we could assess our product performance according to various customer environment scenarios,” says Tardy. “Since we have so many different customers, this really simplified our work, specifically in areas that required thermal evaluations or hose sizing.”

Finally, the use of Simcenter Amesim supported the production and quality check process by pre-determining the product’s resistance and providing a tolerance sensitivity analysis for the main spool valves, taking underlap, pressure forces and flows into account.

Saving time and money

Fluid-System’s R&D department found that Simcenter Amesim software was highly modular and could easily be integrated into the entire simulation process. Its intuitive and user-friendly interface could also handle input from computational fluid dynamics (CFD) software to obtain better models of the pressure flows and hydrodynamic effects.

For example, knowing the flow coefficients and flow forces in the main spool valves helped set better parameters in the Simcenter Amesim models. Only with this type of software collaboration could the team realistically simulate and understand the phenomena happening in the particular value shapes.

The resulting simulation was extremely scalable as well. The amount of data and input specifications only increased as product development advanced. The FluidSystem researchers could sketch a quick functional model during the early stages and develop it into a detailed, highfrequency model for in-depth design analysis.

“Our investment in Simcenter Amesim has tangibly saved us time, money and needless efforts by highlighting potential issues before prototype creation,” says Tardy. “We now spend half the time on prototype adjustment. And we have certainly saved on product touch-ups and late-stage modifications.”

Our investment in Simcenter Amesim has tangibly saved us time, money and needless efforts by highlighting potential issues before prototype creation. We now spend half the time on prototype adjustment.

Fluid-System