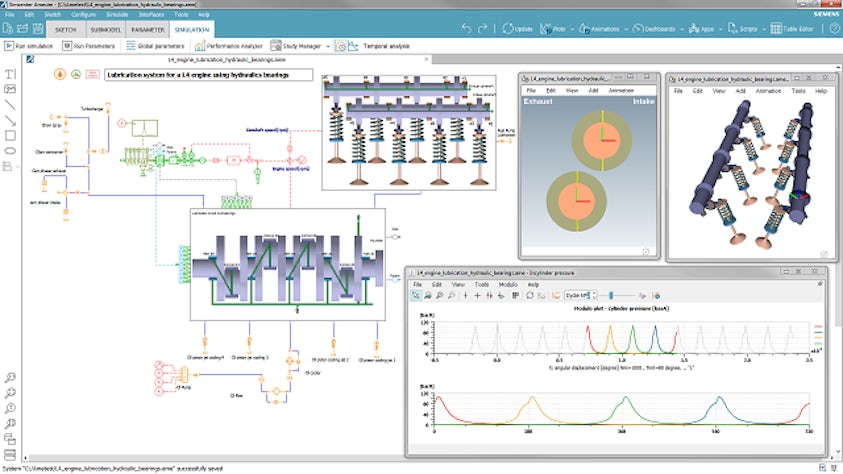

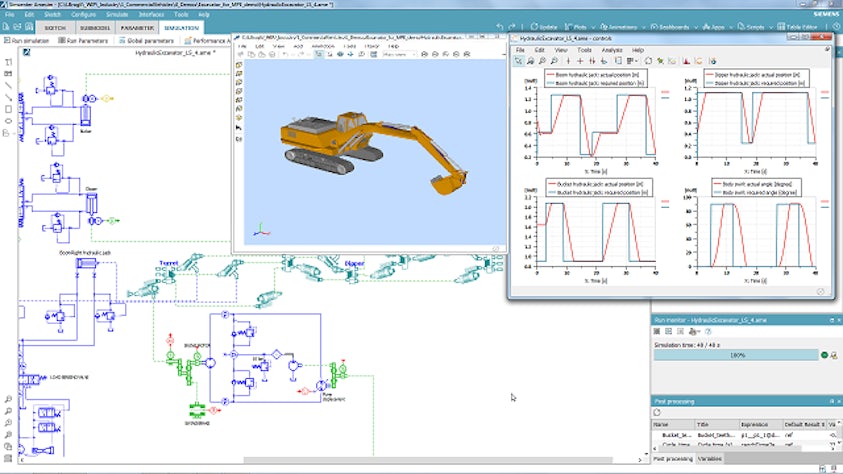

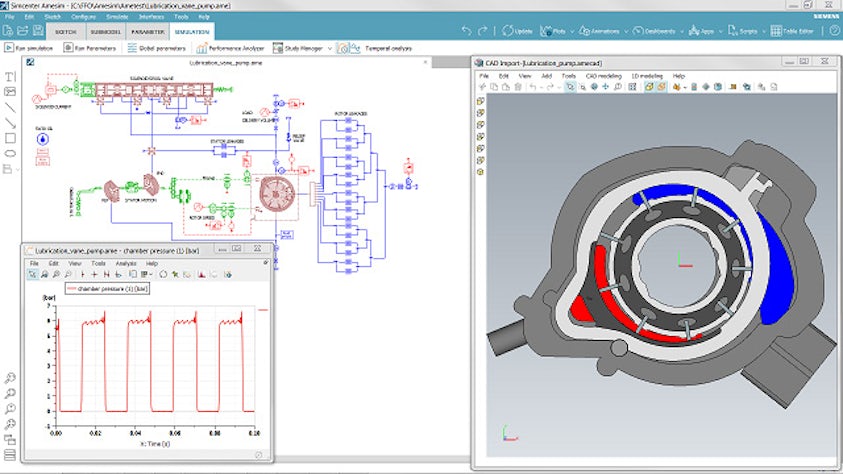

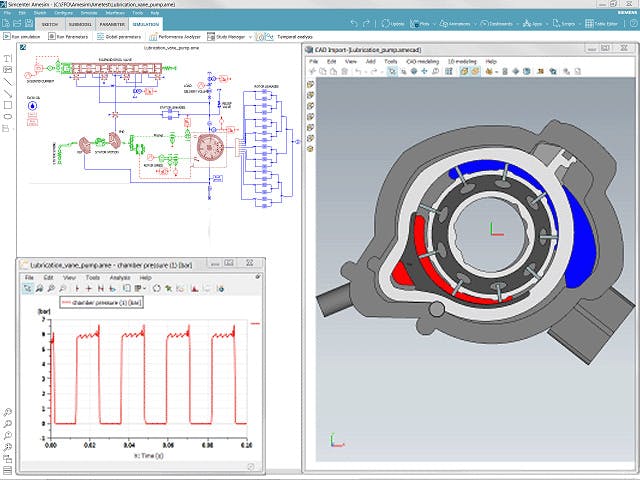

Accelerate the design of your valvetrain, cranktrain, fuel injection, lubrication and cooling systems. Simcenter allows you to size your components, assess and optimize your system efficiency and validate your control strategies. You will be able to prepare the integration of your subsystem within the powertrain environment by evaluating the interaction between the different subsystems and with the combustion chamber, and analyze the impact of your subsystem design on engine performance, fuel economy or emissions.