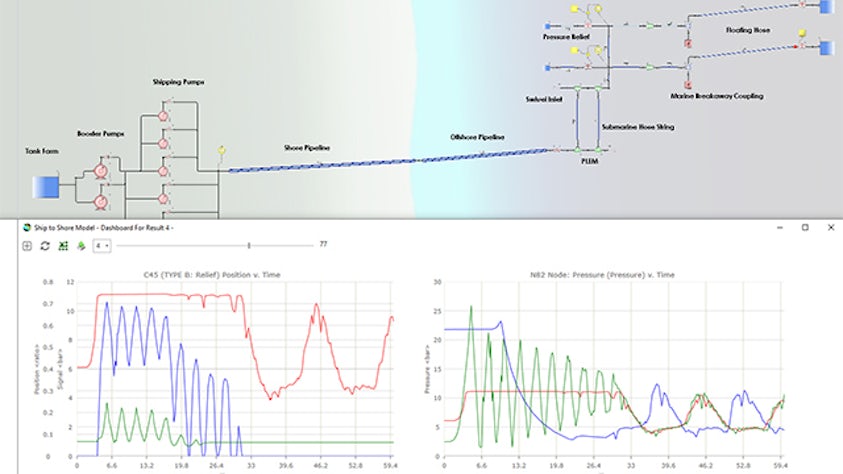

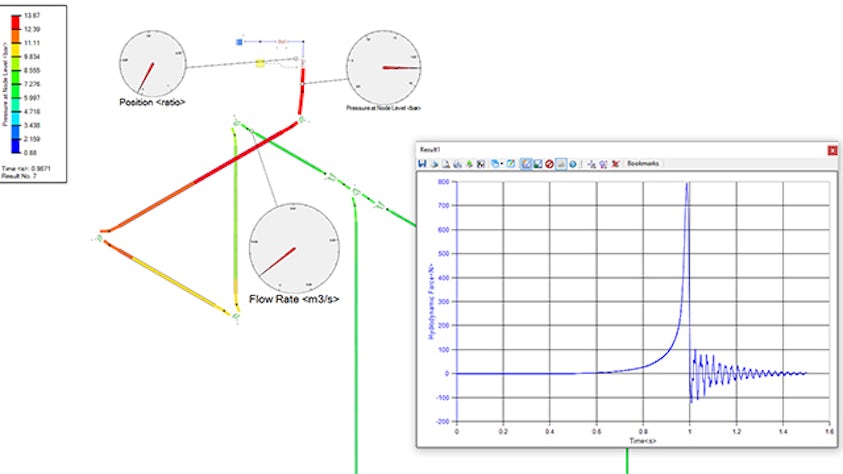

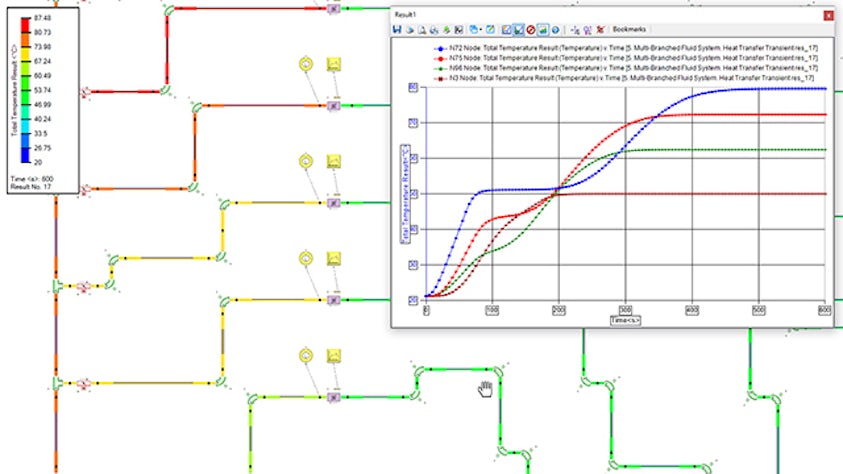

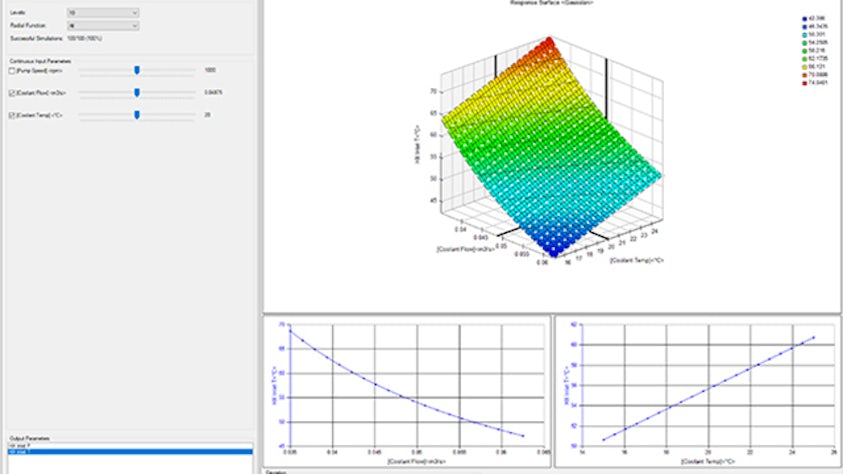

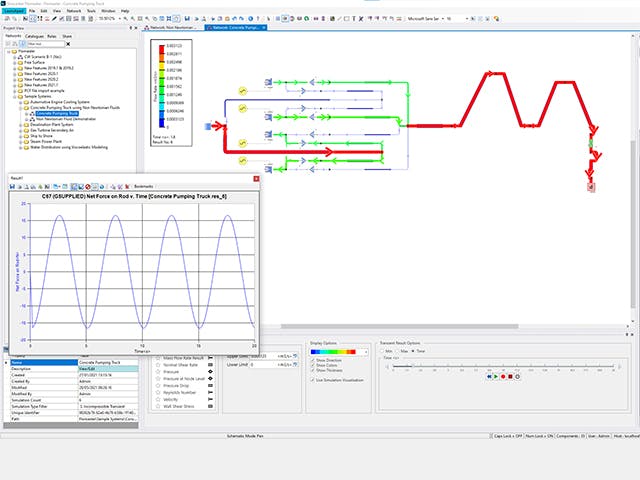

Guarantee safe and efficient operation of thermo-fluid systems under any scenario. With the fast, reliable and rigorously tested transient solver, you can simulate the dynamic behavior of thermo-fluid systems of any size and complexity. Re-use the same models you used during early design for system and component sizing in detailed design for transient analyses. This guarantees model and data continuity throughout the entire engineering phase.

You can analyze the dynamic behavior of the system in critical scenarios like pump failure, emergency valve closure, priming, blowdown and venting. The model accounts for complex phenomena such as pressure surge, line packing, visco-elasticity of plastic pipes, cavitation, chocking and full compressibility of gas.