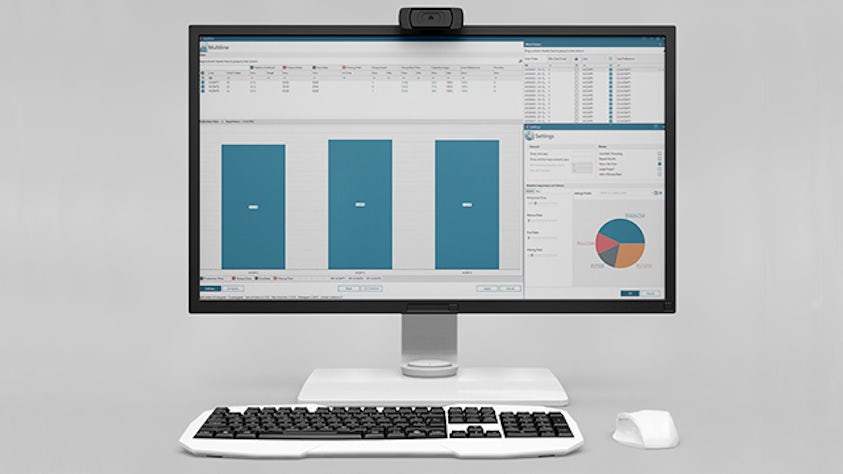

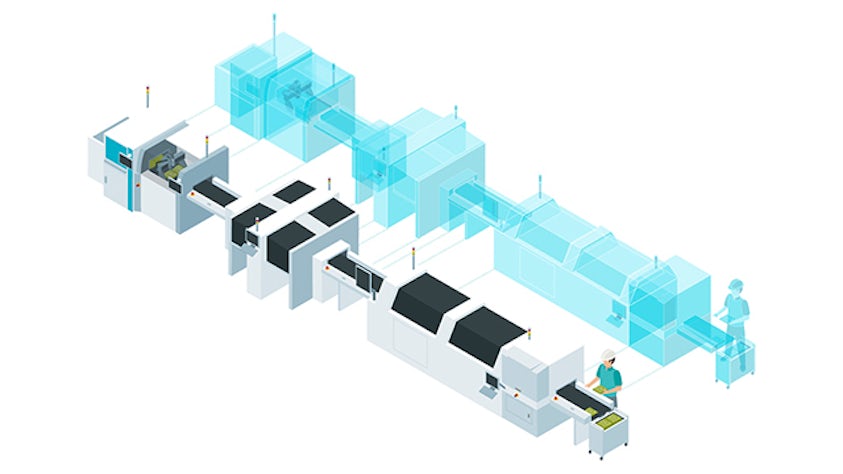

Group products intelligently

Generate optimal product groups. Take into consideration machine capacity, feeder and material availability, and work-order priority. Control optimization parameters, such as due dates, production time and change-overs. Compare different scenarios and then choose the schedule that best fits your needs.