Also called service asset management, physical asset management is often applied to equipment, machinery, devices, vehicles and other complex assets with relatively long product lifecycles.

Physical asset management is typically carried out by asset management software, which is part of a service lifecycle management (SLM) system. Asset management software connects service activities with an asset’s history, operational status, unplanned downtime, regulated maintenance requirements, current configuration and more.

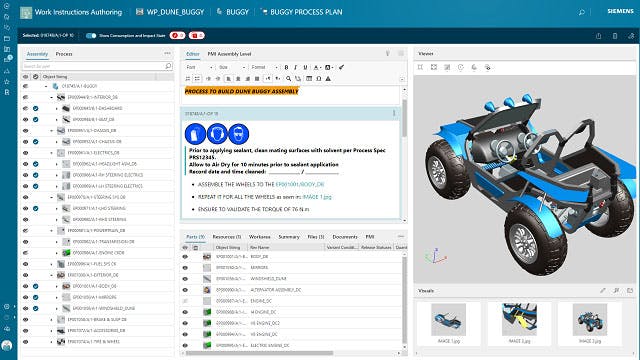

Physical asset management software gathers and maintains updated asset-specific information as services are performed. It also provides service technicians with up-to-date asset configuration information, service materials such as parts and kits, and the technical documentation the technicians need to perform rapid, right-the-first-time service. The software also provides an open ecosystem that is visible and accessible to OEMs, customers and third parties involved in delivering effective service of managed assets.

A comprehensive, actionable digital twin, a virtual representation containing the managed asset's up-to-date physical structure, is critical to physical asset management. This digital twin comprises all the mechanical, electrical/electronic, software and associated document-related components of each asset as well as the status and history of their operational use.

Related products: Teamcenter Service Lifecycle Management