Assembly planning is the process employed by manufacturers to create, simulate, and optimize assembly operations. Although assembly process planning has been around for as long as assembly lines have, today's assembly planning is supported by advanced digital manufacturing software. A wide-ranging set of digital tools work together to help automate and streamline each phase of the production lifecycle for products that rely on assembly processes. Assembly planning is a fundamental aspect of manufacturing process planning, a key element of digital manufacturing.

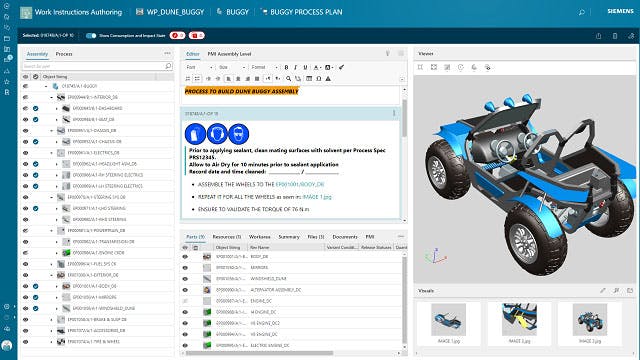

Assembly planning software digitalizes and facilitates process planning workflows, automates planning tasks, and validates plans for product assembly. It also allows design and manufacturing engineers to develop product and assembly process definitions concurrently. Collaboration enabled by the software connects all design/assembly process members into one virtual working group.

The assembly planning software enables manufacturers to execute modern production strategies and consistently deliver high-quality products. Assembly planning software can help connect and optimize entire manufacturing value chains as manufacturers contend with increasingly complex assemblies and supply networks.

Related products: Teamcenter Manufacturing Process Planning | Tecnomatix Manufacturing Process Planning | Teamcenter Easy Plan