Leading automotive parts manufacturer redesigns assembly facility using Tecnomatix plant simulation software

Using a digital twin helps WP secure the company’s future as a leading supplier of radiators for motorcycles and cars

WP Performance Systems

Established in the Netherlands in 1977, the WP Group is a leading supplier of performance-defining components for motorcycles and automobiles. It consists of two main companies. WP Performance Systems GmbH, which designs and manufactures suspension parts such as shock absorbers, front forks and frames as well as exhaust systems, and WP Components GmbH, which produces water and oil radiators. Headquartered in Austria since 2009, the group has more than 600 employees. It manufactures more than a million parts per year, serving market-leading OEMs in Europe, the United States and Asia.

https://www.wp-group.com- Headquarters:

- Munderfing, Austria

- Products:

- General, Tecnomatix

- Industry Sector:

- Automotive & transportation

Based on the times previously required for each process step, this resulted in a simulated output of 1,500 water or 1,630 oil radiators per day achieved by the existing assembly team without overtime. In reality, however, it turned out that the same personnel worked faster in the new environment so that we effectively doubled our production capacity

WP Performance Systems

Performance-focused components

Whenever there is a trophy to be won in motorcycle racing, you will find components and subsystems of the WP Group at the starting line. Whether on or off the road, they dominate events like the Dakar Rally and have won more than 300 World Cup titles. Since they focus on vehicle performance as well as user experience, WP components are used by virtually all major motorcycle racing teams and manufacturers.

Originally founded in the Netherlands in 1977, WP Group is now part of the KTM/ Husqvarna Group and based in Austria. It consists of two companies. While WP Performance Systems GmbH develops suspension components such as shock absorbers, steering dampers, front forks and frames as well as exhaust systems for motorcycles, WP Components GmbH designs and manufactures oil and water radiators for motorcycles and performance vehicles.

The WP Group is a leading supplier of performance defining components for motorcycles and automobiles, including shock absorbers, front forks and frames as well as exhaust systems and radiators.

Uncovering bottlenecks

“Nearly every motorcycle produced in Europe has a WP radiator on board”, says Harald Edlinger, industrial engineering manager at WP Performance Systems. “In total, we produce 400,000 radiators per year in more than 200 different custom-made products.” Although WP also operates a radiator plant in China, the company manufactures nearly 90 percent of these radiators in Munderfing, near Salzburg, Austria.

Although this quantity is not particularly high for automotive components, the volume has grown rapidly since the production facility opened in 2012, and so has model variety. Increasingly, assembly workers had to work overtime to meet the production requirements. In his bachelor’s thesis at the Technical University of Graz in 2014, Fabian Steinbacher, project manager at WP Performance Systems, conducted a material flow analysis of the radiator assembly process.

“The workshop-like environment in which all radiators were assembled on an array of individual stations was hampering the material flow,” he says. “To address this problem, I pursued a solution path involving the separation of high and low runners and flow production for the high-quantity parts.”

Within the WP group, WP Components produces 400,000 radiators per year. With 200 different models, diversity is high.

Optimization by simulation

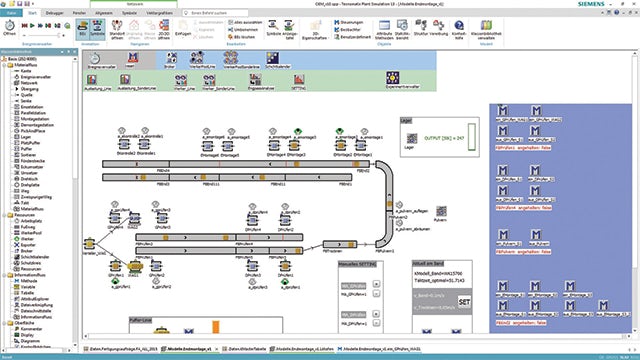

In a second project, Steinbacher investigated the feasibility of various concepts to rearrange the radiator assembly. To build and optimize the digital twin of the radiator assembly facility, he used the Plant Simulation solution in the Tecnomatix® portfolio from Siemens Digital Industries Software, a leading supplier of product lifecycle management (PLM) software. The Tecnomatix portfolio includes software products for the digital factory primarily used by original equipment manufacturers (OEMs) and suppliers to streamline their production lines, but providing the scalability needed to adapt to smaller applications.

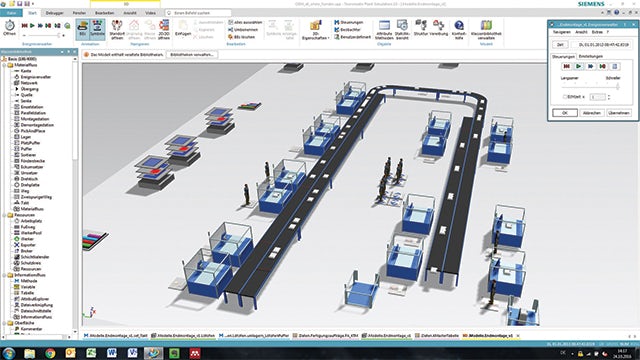

Steinbacher had already gained experience with the Tecnomatix software at his university. The software enables him to simulate different scenarios in a realistic manner, optimizing the internal material flow. Using the 2D and 3D capabilities of Plant Simulation, Steinbacher was able to create a functional model of the entire radiator assembly facility, including the workers at their stations, within a few weeks. “With the SimTalk advanced simulation programming language in Plant Simulation, it is easy to add and modify special features as needed,” he says.

“What I find particularly useful is the ability of Plant Simulation to automatically reallocate the employees dynamically among the stations to optimize throughput depending on the time required for individual processing.”

WP finally used a continuous conveyor system for flow production of the highvolume products and performed low-volume assembly in a separate workflow. The U-shaped conveyor not only saves space; it also maintains short distances between the ten flexibly manned work stations along the conveyor, so tasks can be redistributed quickly and easily to reflect requirements of different production lots. Workers take the radiators from one of two conveyors that run in parallel and return them to the other to prevent radiators bypassing production steps.

Using Tecnomatix software from Siemens Digital Industries Software, WP manufacturing engineers optimized the production environment for radiator production

Doubling output capacity

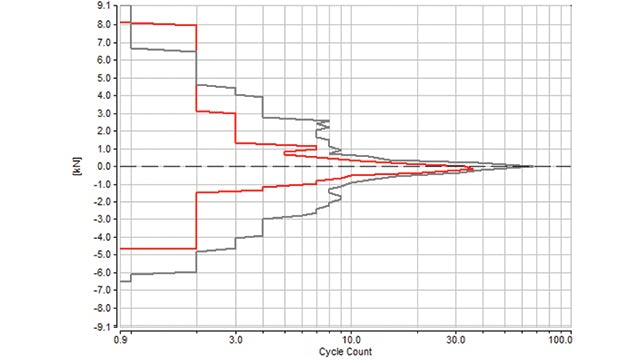

The entire process of creating and optimizing the material flow using the digital twin of the production plant was achieved in less than three months. Part of the task was also to find out whether single-shift operations were sufficient or if a second shift would be required. “It turned out that there is a limit for the number of employees who can work on the same batch in parallel,” says Edlinger. “The 1,200 radiators the new facility would be able to turn out in single-shift operations without overtime were better than before, but they were also the minimum.” As WP has no plans to stop growing or rebuild the assembly hall in the short term, the manufacturing engineers pursued the two-shift approach. “Based on the times previously required for each process step, this resulted in a simulated output of 1,500 water or 1,630 oil radiators per day achieved by the existing assembly team without overtime,” says Steinbacher. “In reality, however, it turned out that the same personnel worked faster in the new environment so that we effectively doubled our production capacity.”

Building the digital twin of the radiator production line allowed the WP manufacturing engineers to include worker-related actions.

Investment decision hedged by digital twin

“The actual investment for redesigning our radiator assembly system was significant, but not as high as we feared,” says Edlinger. “It is, however, a good feeling that it is based on reliable simulation results so that all the optimizations and fine-tuning have been done before installation and not during operation.” An effective doubling of production capacity is not the only advantage of the simulation-based remodeling and introduction of the two-shift operation. This arrangement is also less sensitive to disruptions, requires fewer tools and generally reduces investment and improves capacity utilization.

Another favorable side-effect of the capacity increase is the reduction of work-in-process by 60 percent. “The most important effect, however, is the reduction of overtime work by 85 percent, or the equivalent of 5.2 full-time workers,” Edlinger adds. “Following the success of this project we have decided to create digital twins of all our production facilities for optimization with concrete projects in other parts of the company already underway.”

Separating the A parts from the lower quantity varieties and building them in a cyclic flow production along a U-shaped conveyor allowed WP Components to increase output by 40 percent without requiring more room or extra workers.

To assist workers in critical steps, such as pressure testing, conveyors for untreated and treated radiators run in parallel to easily avoid omissions.

The most important effect, however, is the reduction of overtime work by 85 percent or the equivalent of 5.2 full-time workers.

WP Performance Systems