Construction engineering firm uses NX to achieve improved efficiency and profitability

Siemens Digital Industries Software solution enables Obermeyer to realize shorter planning cycles and higher quality construction plans and processes

Obermeyer

The Obermeyer Corporate Group (Obermeyer) is an independent engineering consultancy that offers technical and integrated planning for nearly all fields of construction planning, including buildings, transportation infrastructure, energy and environment. Obermeyer was founded in 1958 and has more than 1,200 employees worldwide.

https://www.opb.de/- Headquarters:

- Munich, Germany

- Products:

- NX

The use of NX clearly gives us more efficiency, more profitability and better consistency in our processes; and in general, higher quantity and quality in our planning.

Obermeyer

Independent engineering consultancy

The Obermeyer Corporate Group (Obermeyer) is an independent engineering consultancy that offers technical and integrated planning for nearly all fields of construction planning, including buildings, transportation infrastructure, energy and environment. The firm provides project control and object monitoring as part of its service portfolio. Obermeyer was founded in 1958 and is headquartered in Munich, Germany. It has more than 1,200 employees worldwide.

Heterogeneous IT landscape

The very complex planning processes and calculations that Obermeyer requires for its projects means the company needs to use a range of specific, specialized information technology (IT) solutions. Markus Hochmuth, head of special section building information modeling (BIM) for Civil Engineering at Obermeyer, explains: “We need to unify our IT environment and establish a consistent and integrated planning process, including our BIM process, which is an increasingly important element in the construction industry.”

BIM is a method for optimizing the planning, realization and operation of buildings Construction Obermeyer Construction engineering firm uses NX to achieve improved efficiency and profitability with the use of software tools. The basis of the BIM process is an object-oriented 3D model, which allows firms to use and link a variety of data in subsequent processes.

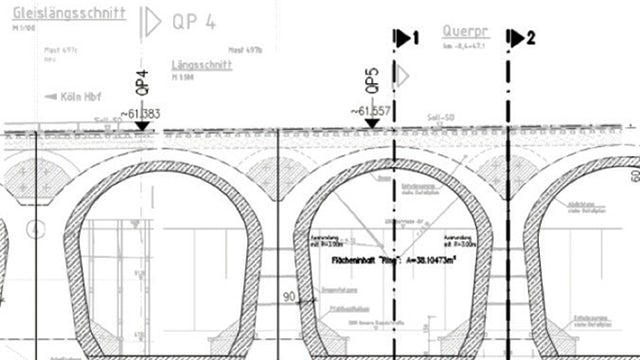

Existing railway bridge in Cologne in need of renovation. Copyright: Obermeyer

Selecting the right 3D CAD solution

Construction designs for roads, railroad lines, bridges and other transportation projects have to be adjusted to the topology of the surrounding area. They often follow complex curves and freeform surfaces. To better support the BIM process with 3D modeling, Obermeyer searched for an appropriate 3D computer-aided design (CAD) system to be used for traffic structures and bridges.

“When designing a bridge, specific processes can often be parameterized,” says Hochmuth. “It was our objective to optimize the planning processes with software that allows us to execute our tasks more efficiently and with higher quality, which was difficult to do using our existing planning tools. By using 2D CAD, the representation of the transverse section, the longitudinal section and the gradient is very time consuming and prone to errors, particularly when variants have to be investigated or changes have to be made.”

He notes, “The use of 3D CAD for product design is standard in most segments of the manufacturing industry. Therefore, we have tested software systems that are used in these industries, because most of the architectural CAD solutions are focused on the definition of planes and verticals.”

The selection process included a number of leading 3D-based CAD systems. Software was evaluated using the example of a bridge design to see if the tested solutions could support standardization and optimization of the processes and how that would improve profitability, efficiency and quality. Furthermore, the new solution needed to allow the integration of existing planning processes and procedures, such as specialized software for route surveying and solutions for the bidding process.

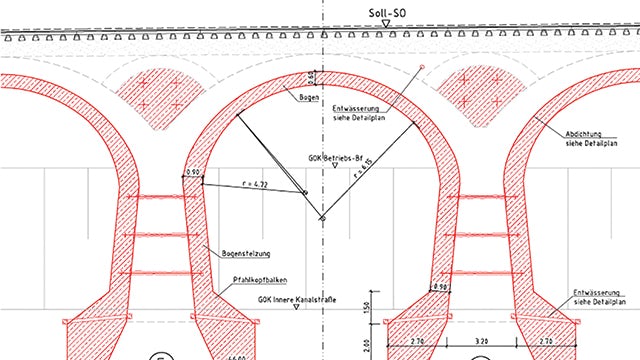

Alternative proposal of Obermeyer and Falkenhahn Bau now being implemented. Copyright: Obermeyer

Original plan of the contractor. Copyright: DB Projektbau GmbH

NX gets the nod

“Based on the selection process, we decided to use NX from Siemens Digital Industries Software because it offered the best possibility for integration with our existing planning processes, and because we expected the most output from the 3D model in regard to the derived 2D construction plans,” says Hochmuth. “Although this could have somehow been achieved with all tested systems, NX offered us the most comprehensive and efficient tools. Even more important was the cooperation of Siemens with NeoApps, which develops a variety of construction-specific applications.”

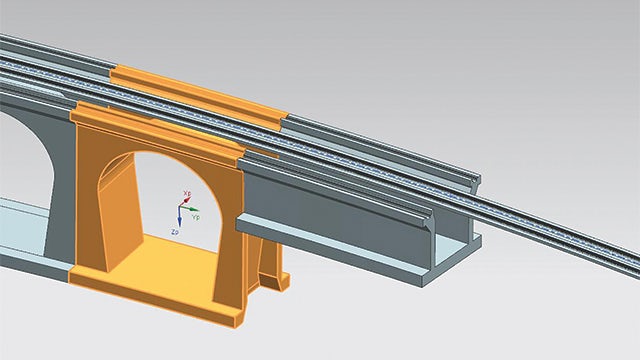

As in other industries, 3D modeling offers many advantages, but for Obermeyer it is only an expedient. Industry-certified, approved 2D construction plans are produced prior to the realization of building projects.

“It is very important for us to quickly generate 2D plans directly out of the 3D model, not with separate, time-consuming downstream solutions or by transferring the data to our 2D system,” says Hochmuth. “This would break our design chain, particularly because making changes would take a lot of effort and could lead to errors.”

Obermeyer avoids such problems by using NX and the NeoApps drafting solution. The models and 2D drawings created using NX are associative. Architectural, engineering and construction (AEC) industry requirements are reflected in the NeoApps solution AEC Drafting. Therefore, any changes to the model are updated automatically and in accordance with industry standards.

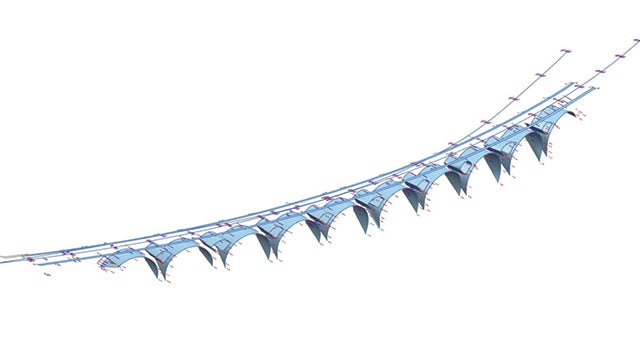

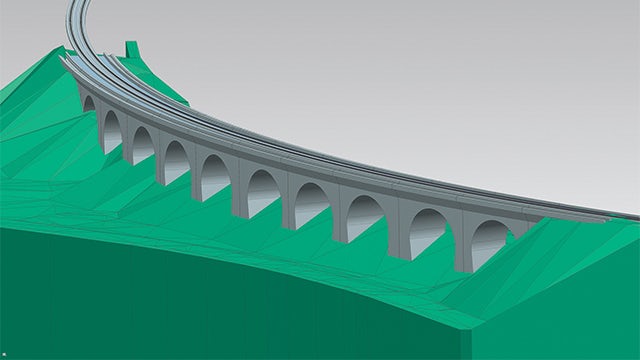

Using NX to create freeform surfaces. Copyright: Obermeyer

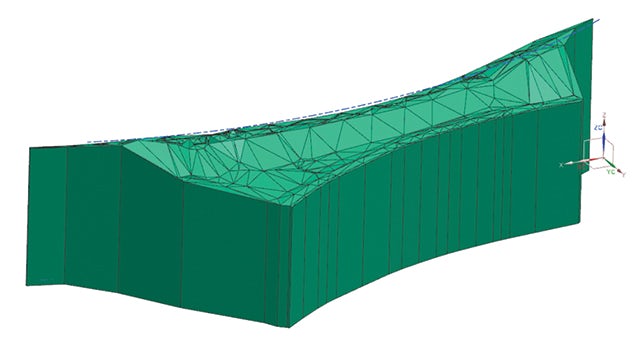

Triangle terrain model created with ProVI software imported into NX. Copyright: Obermeyer

The efficiency factor

A good example of the efficiency that results from using NX is the renovation of a railway bridge in Cologne, Germany. Positioned between a very busy road and a freight yard depot, and because the line could not be redirected, the stabilization work has to be done under running railway traffic.

The contracting authority, the Deutsche Bahn (German Railway), planned to renovate a viaduct that was built in 1912, a vault bridge with 12 arches and a length of about 200 meters. The objective of the project was to stabilize the existing construction with new reinforced concrete shells.

Obermeyer worked with the building firm Falkenhahn Bau to come up with an alternative proposal, which was accepted. Rather than constructing a deep foundation, the new arches are designed with base plates, which are stiffly connected with the imposts.

The arch form and the burden of the geographical environment led to complex geometrical conditions. For the modeling of the new concrete shells, some defined points in the existing arches were measured and used for the definition of freeform surfaces with NX. These freeform surfaces were used as the basis for the design of the new arches.

In addition, a digital terrain model – including the position of the railway line – was created, which was also based on measurements on site.

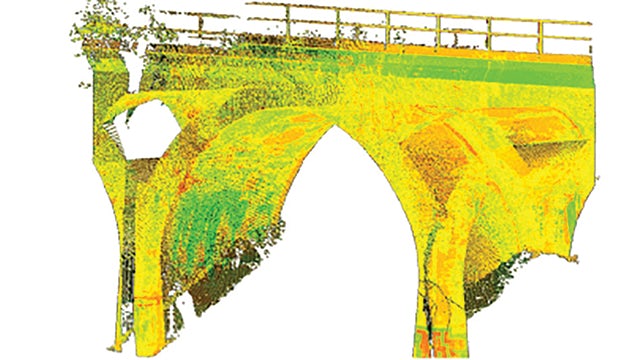

To make sure that splines and freeform surfaces defined with NX accurately fit the existing stone arches, one arch was completely scanned in 3D. The difference between the results and the created surfaces from just a few measuring points were within tolerance and, therefore, acceptable.

The 3D model was also used to generate the certified 2D plans and to calculate the required cubic capacity, which will be used by the building contractors.

A 3D model of the new bridge; the new bridge shown within the terrain. Copyright: Obermeyer

3D scan of one arch. Copyright: Ingenieurbüro Dr. Sauermann – Orlicek – Rohen GmbH

A clear advantage using NX

“The use of NX clearly gives us more efficiency, more profitability and better consistency in our processes; and in general, higher quantity and quality in our planning,” says Hochmuth. “We are only beginning to use NX, but we already see a highly productive tool that will fit our requirements in regard to quality and transparency as well as adherence to costs and delivery dates.”

Additional advantages of using NX, notes Hochmuth, are parameterized models and more transparent for the customers through virtual, quickly changeable visualizations, which can include the geographical surroundings. Another added value is that the model data can be re-used for subsequent processes.

The 3D planning is extremely important for the BIM process, because only 3D object models can contain the required information for processes such as 2D drawing creation, finite element modeling (FEM) and cost calculations.

Outlook

According to Hochmuth, the trend toward broad use of 3D tools for planning purposes is expected to continue. Obermeyer already uses BIM methods for building construction and has created – with its partner company AEC3 – the BIM guideline for Germany, which is published in the Federal Institute for Research on Building, Urban Affairs and Spatial Development (BBSR).

However, global planning in the construction industry is not limited to 3D CAD. Hochmuth is convinced that the connectivity of the different software tools will be even more important. “Besides enhanced 3D CAD use, it will be essential to establish an overall data management tool, which can be used to manage all the increasing digital data, control the processes and leverage all involved software tools,” concludes Hochmuth. As an example, he points out that all the data for a bridge structure should be stored digitally with required information, from the first idea through the planning process, realization, utilization and maintenance until removal.

Using NX to produce a mass calculation. Copyright: Obermeyer

We are only beginning to use NX, but we already see a highly productive tool that will fit our requirements in regard to quality and transparency as well as adherence to costs and delivery dates.

Obermeyer