How can you produce highly precise, high-quality, customized and sustainable components on time and at scale — all while improving your overall productivity and profitability?

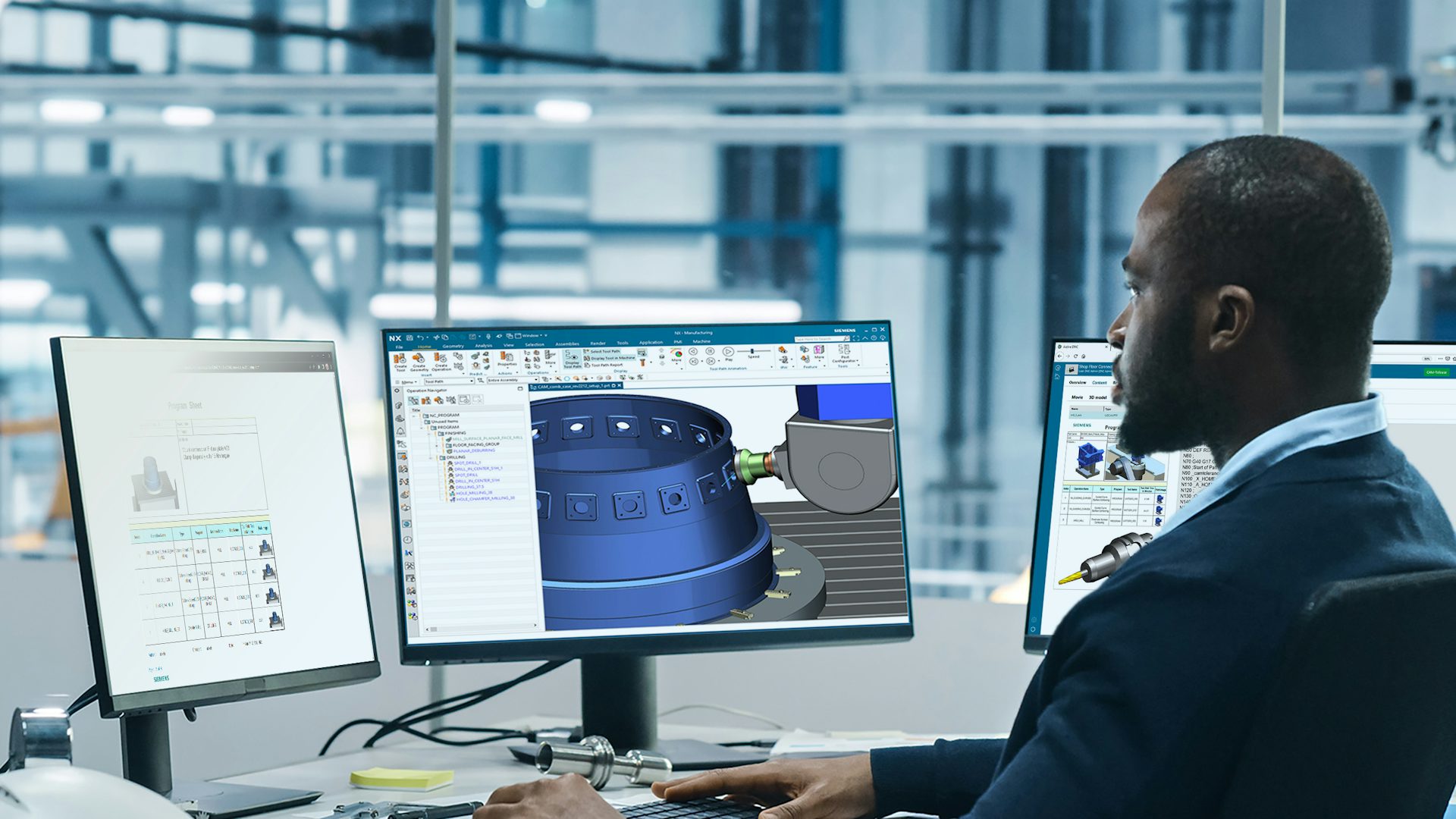

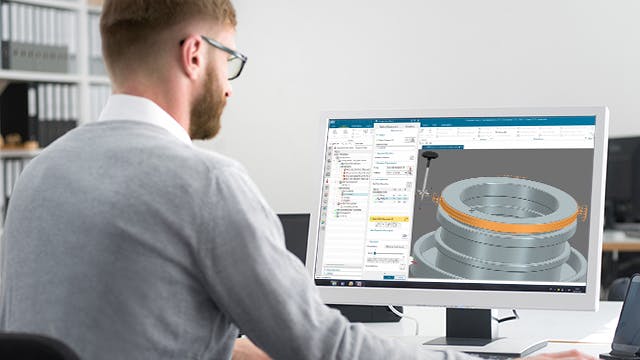

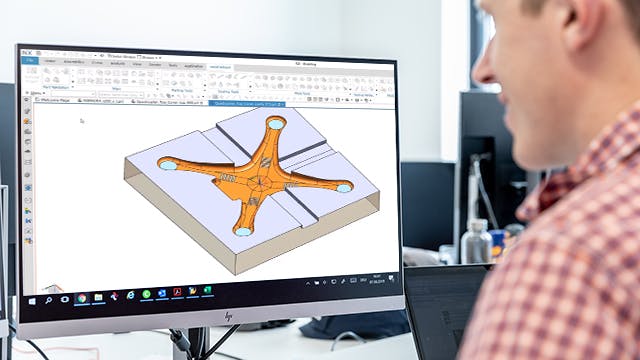

Implement an integrated software solution for tooling and part manufacturing. Automate and seamlessly connect design, production and operations in the digital machine shop using a proven, powerful suite of software tools and solutions.