What is smart manufacturing in aerospace and defense?

Smart manufacturing in aerospace and defense involves updating production processes to increase efficiency and reduce risk. It starts with connecting engineering to the shop floor with a model-based manufacturing plan. Leverage a digital twin to validate that plan virtually before physical commissioning. Finally, implement advanced manufacturing technologies to help continuously optimize products and processes.

Build your aerospace factory of the future today

Digitally transforming your aerospace and defense manufacturing processes can help you optimize your factory floor and accelerate production startup. Aerospace manufacturers who adopt a smart manufacturing process can achieve key benefits:

Reduction in commissioning time

Accelerate digital transformation to increase production output and flexibility while optimizing quality. (Airborne)

Improvement in throughput

Meet aerospace production targets and increase competitive advantage across your manufacturing process. (Deloitte)

Reduction in labor time

Achieve reductions in detailed structural design time by using our smart manufacturing solutions. (General Atomics Aeronautical Systems, Inc.)

Digitally transform your aerospace production process

Connect engineering disciplines and processes, plan, optimize and test your factory floor virtually and accelerate production ramp-up to meet production throughput targets faster. Explore the key pillars of smart manufacturing for aerospace and defense:

Modernize your aerospace manufacturing processes by connecting data from all engineering disciplines to the shop floor to create a model-based manufacturing plan. This "shift left" approach helps ensure right-first-time production with products that conform to design specifications.

Update your legacy equipment with smart technologies to create a comprehensive digital twin. Simulate manufacturing scenarios to optimize operations. This allows you to virtually validate your manufacturing plan before physical commissioning and achieve a smart factory floor faster.

Create a flexible, connected aerospace factory of the future by monitoring performance and predicting operational issues in real time using sensors and smart devices. Establishing this closed-loop process will increase the flexibility and visibility of your manufacturing environment.

Optimize your aerospace production strategy

On-time delivery rate

Customer achieved up to a 96% on-time delivery rate while managing diverse materials and part types. (Proform)

Increase in output

Use automation and digitalization to uncover bottlenecks and optimize production. (Airborne)

Increased production capacity

Reduce production lead-time and increase capacity and utilization. (GKN Aerospace)

High-precision manufacturer pursues digitalization with Siemens Digital Industries Software solutions

Company:Armor Meca

Industry:Aerospace & defense

Location:Pleslin-Trigavou, France

Siemens Software:NX, Opcenter APS, Teamcenter

"With Siemens software solutions, we effectively automate our production methods by implementing digital twins of our machine tools and optimizing our production flows."

Explore our resource library

Learn more about managing change in the A&D industry and how to leverage digital transformation in manufacturing. Discover blogs, ebooks and more to leverage these concepts and achieve digital transformation in your manufacturing process for long-term success.

Smart solutions for aerospace manufacturing success

Manufacturing process planning

Wire harness manufacturing

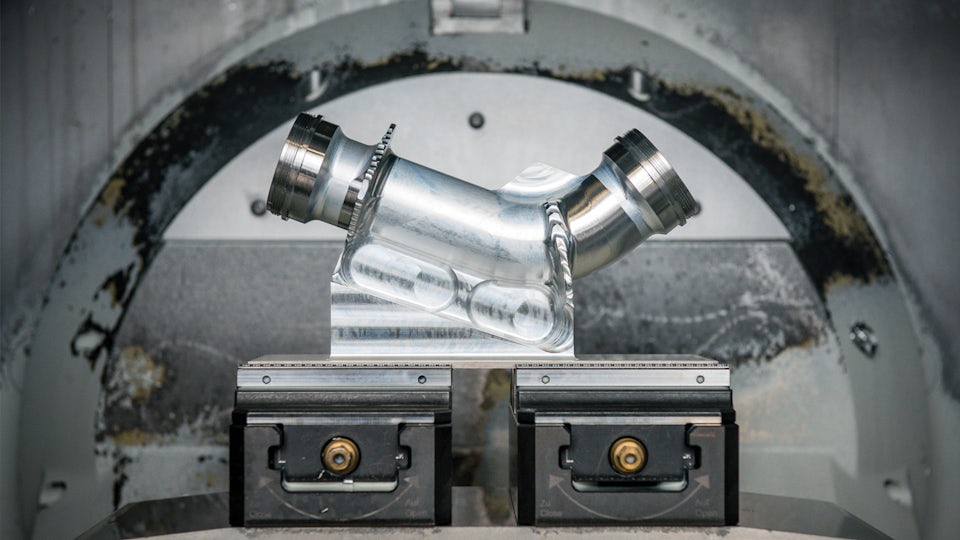

Tooling and part manufacturing

Manufacturing execution management

Quality management

Additive engineering & manufacturing

Frequently asked questions

How can I increase the chances that my aerospace products will consistently conform to their approved design?

To ensure right-first-time production for your aerospace products, you need to implement a smart manufacturing approach. This approach to aerospace production involves:

- Creating a model-based manufacturing plan that connects your engineering data to shop the floor

- Leveraging a digital twin of your aerospace factory, which allows you to virtually test your factory floor and validate your production plan

- Implementing advanced manufacturing technologies and closed-loop operation insights to predict and mitigate issues and continuously improve products and processes

How does aerospace engineering software accelerate production?

Our solutions can help you accelerate production by designing jigs, fixtures, gages and other tooling equipment for manufacturing operations to exact specifications.

Why is additive manufacturing important in aerospace?

Aerospace manufacturers are facing increased pressure to deliver products faster while still conforming to design. Additive manufacturing in aerospace can help improve efficiency by prototyping 3D-printed tools, jigs, fixtures and finished goods. This approach gets raw material close to the finished part, minimizing raw material cost and waste. By making parts on an as-needed basis at the location of service, additive manufacturing reduces inventory and shipping costs. Additive manufacturing, supported by our Siemens Xcelerator solutions, allows companies to reimagine products, retool manufacturing and rethink business models.

What is the future of composites in aerospace?

Aerospace composites are increasingly important as they help manufacturers satisfy key requirements such as reducing weight, increasing payload and reducing fuel consumption. To realize these benefits, aerospace and defense manufacturers must be able to design and manufacture composite components with high precision and production yields, as well as operational durability and repairability. Solutions within the Siemens Xcelerator portfolio can support composite engineering design and manufacturing.

How does automation benefit aerospace manufacturing?

Automation in aerospace manufacturing helps improve efficiency, safety and throughput. Robotics and artificial intelligence are speeding up operations, while sensors and smart devices are monitoring performance and predicting operational issues in real-time.

How does Siemens software support aerospace manufacturing, including aerospace parts manufacturing?

Our smart manufacturing solutions enable companies to accelerate digital transformation of the entire production process. With our Siemens Xcelerator portfolio of software solutions, you can connect engineering disciplines and processes; plan, optimize and test your factory floor virtually; and accelerate production ramp-up to meet production throughput targets faster. This ensures visibility across the product lifecycle, allowing you to predictably deliver consistent products that conform to the approved design.

Learn more

Watch

On-demand webinar | Digital transformation in aerospace manufacturing

Video | Smart manufacturing in aerospace and defense

Read

Ebook | Smart manufacturing solutions in aerospace

Ebook | Four keys to optimizing A&D production processes

Ebook | Digital solutions for modernizing A&D manufacturing execution

Explore

Resource library | Wire harness manufacturing in aerospace

Resource library | Modernize manufacturing processes in aerospace

Resource library | Manufacturing operations management in aerospace