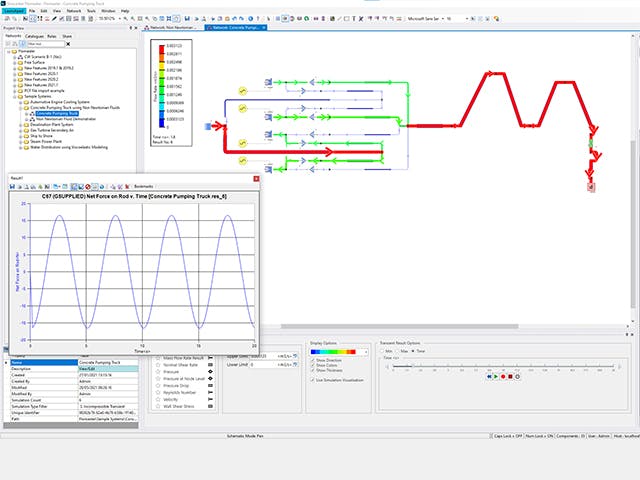

Zmaksymalizuj zwrot z inwestycji, wykorzystując cyfrowego bliźniaka układu termiczno-przepływowego w całym cyklu życia produktu, Możesz ponownie użyć modelu zbudowanego w fazie projektowania jako wykonywalnego cyfrowego bliźniaka do obsługi zaopatrzenia, rozruchu i eksploatacji.

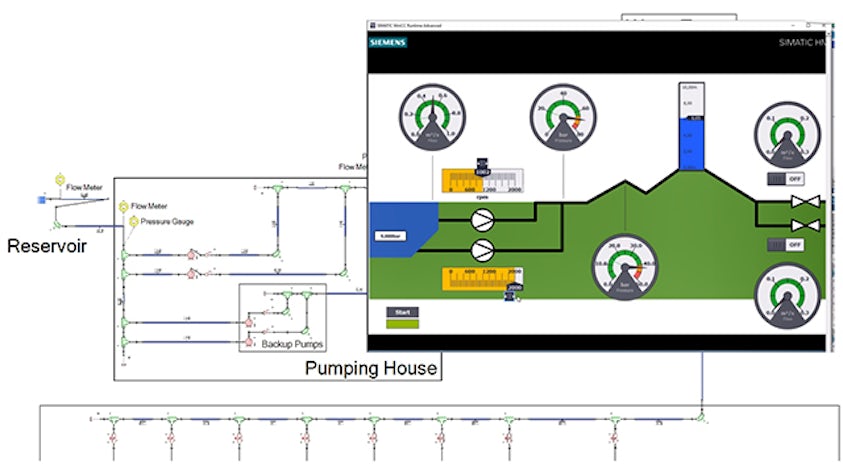

Przeprowadź optymalizację projektu opartą na kosztach, aby zminimalizować wydatki kapitałowe i operacyjne oraz wspomagać procesy zaopatrzenia. Podłącz cyfrowego bliźniaka układu termiczno-przepływowego do wirtualnego programowalnego sterownika logicznego, aby zweryfikować ich interakcje w bezpiecznym środowisku wirtualnym przed zbudowaniem fizycznego systemu. Możesz wreszcie też wykonywalnego cyfrowego bliźniaka z rzeczywistymi sensorami i sterownikami za pośrednictwem przemysłowego Internetu rzeczy (IoT), aby rozszerzyć dostępne informacje w celu zwiększenia wydajności i bezpieczeństwa eksploatacji systemu.

Zmniejszenie kosztów przy jednoczesnej poprawie bezpieczeństwa wszystkich złożonych układy termiczno-przepływowych

Układy hydrauliczne są używane do różnych zadań, w tym chłodzenia i ogrzewania, transportu produktów, wytwarzania energii i zapewniania ogólnego bezpieczeństwa instalacji. Dlatego też zoptymalizowanie ich wydajności i bezpieczeństwa ma ogromne znaczenie.