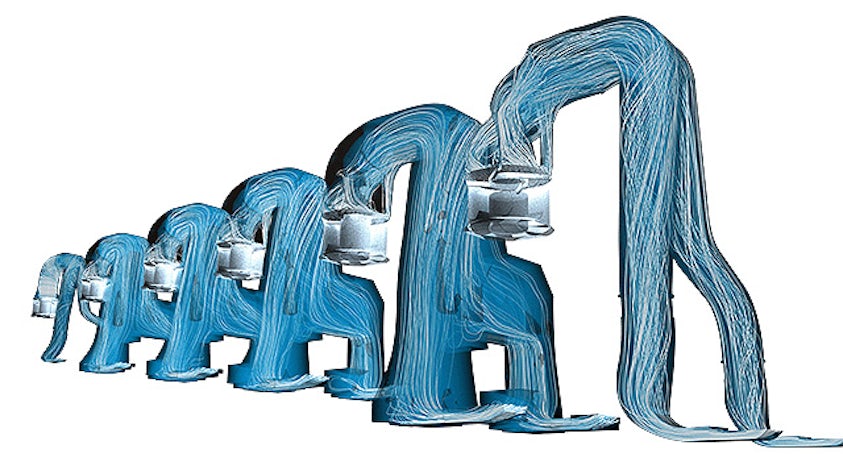

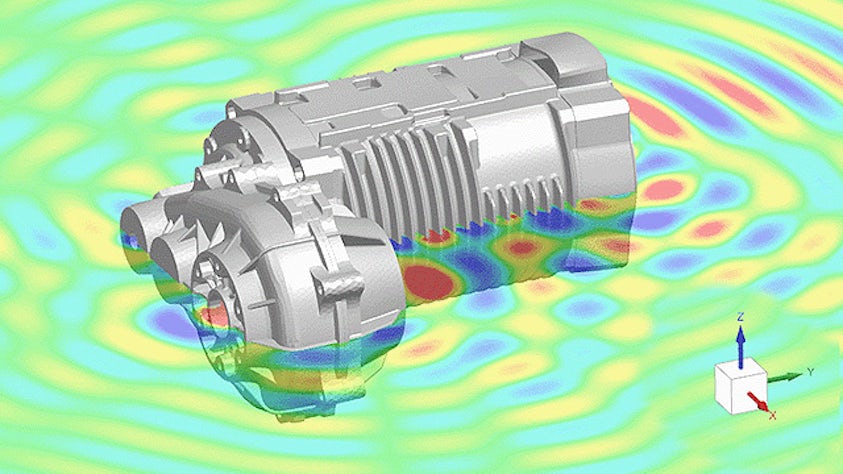

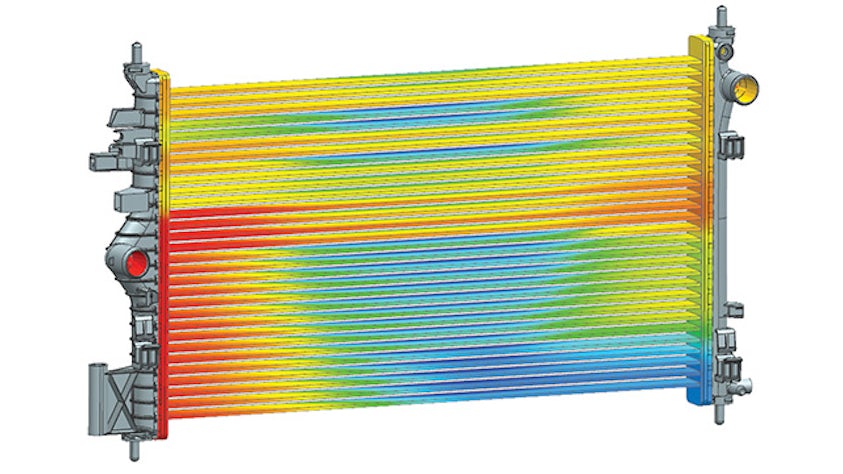

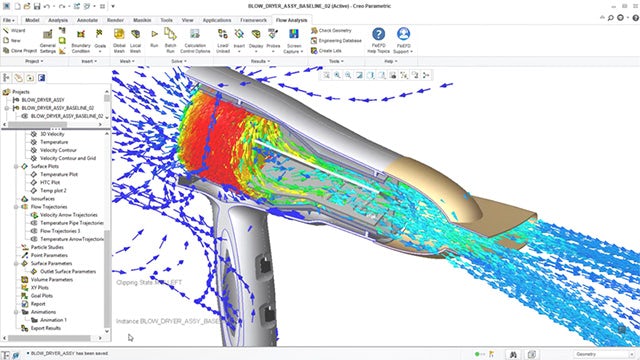

Rzeczywiste działanie wielu produktów zależy od ich wzajemnych oddziaływań z płynami: gazami, cieczami lub ich połączeniem. Rozwiązanie do symulacji obliczeniowej mechaniki płynów (CFD) oferuje możliwość symulowania i prognozowania przepływu oraz przekazywania ciepła. Jednak w obliczu stale rosnącej złożoności produktu analizowanie tych zjawisk w izolacji od innych danych produktu nie jest już wystarczające.

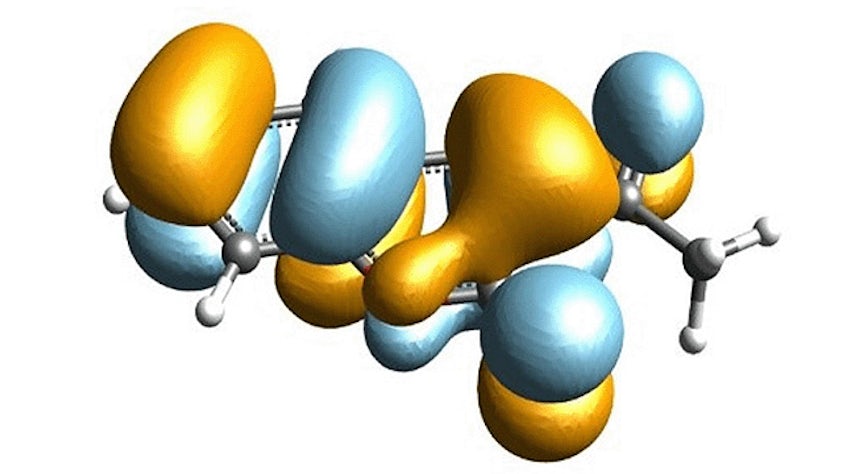

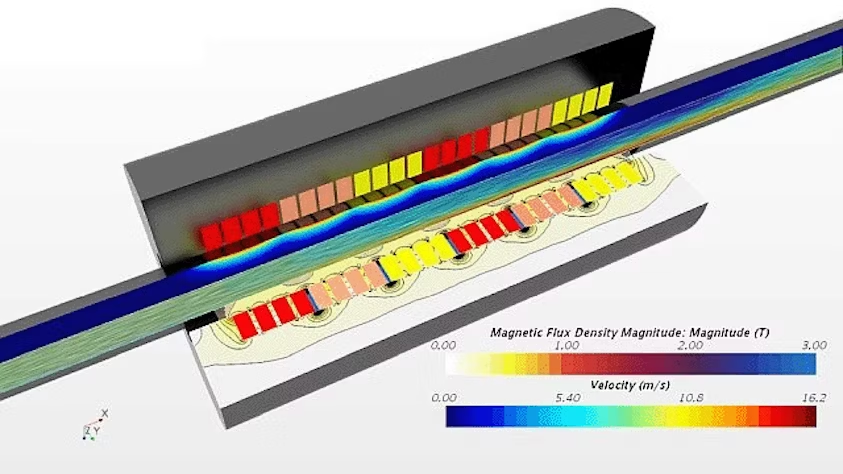

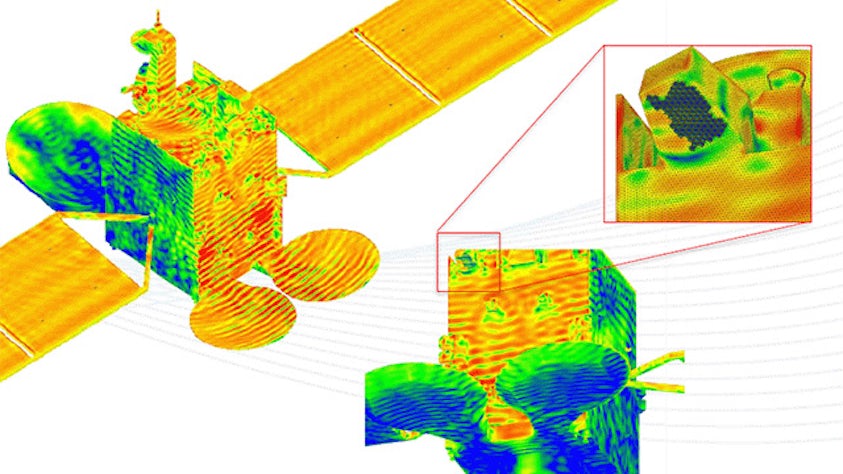

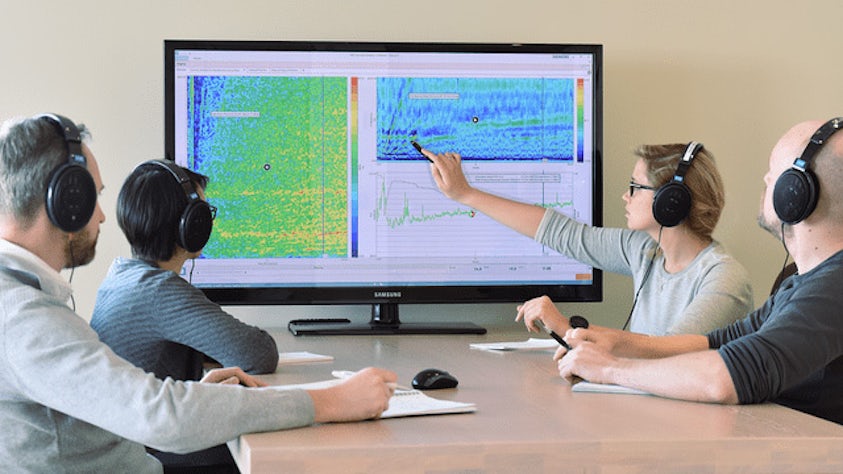

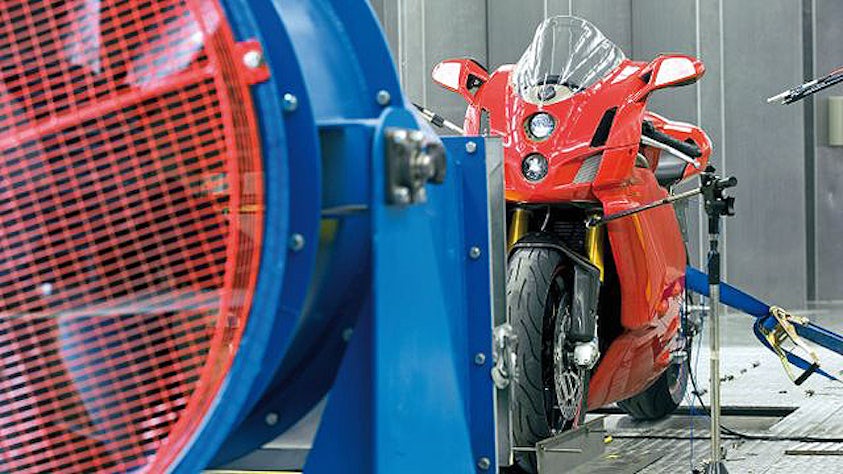

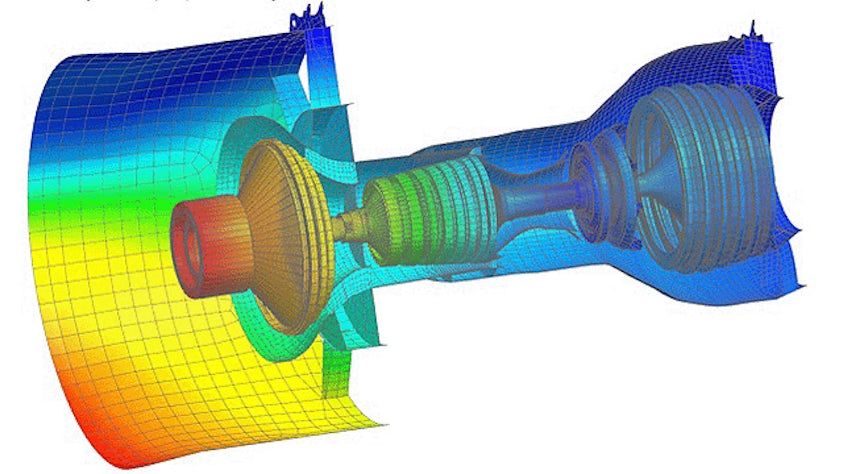

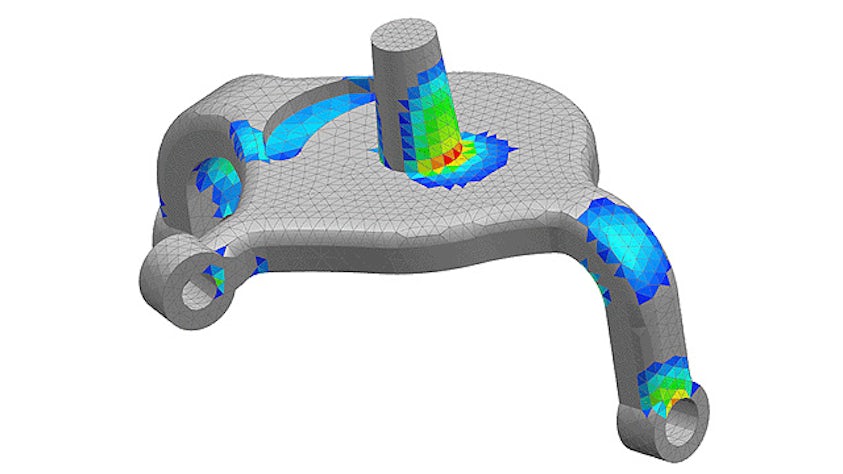

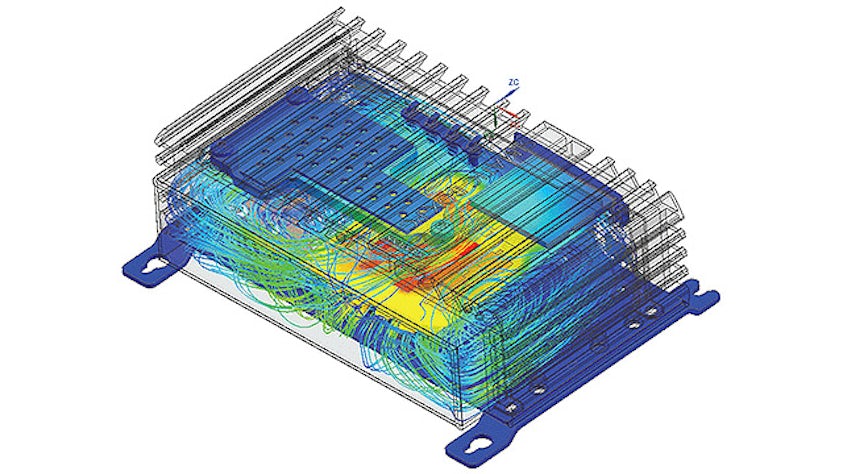

Aby przekształcić złożoność w przewagę konkurencyjną, inżynierowie zajmujący się analizami CFD muszą być w stanie modelować szeroki zakres zjawisk fizycznych związanych z płynami: od przepływów reaktywnych po aeroakustykę, od przepływów wielofazowych po dynamikę cząstek, od chłodzenia układów elektronicznych po aerodynamikę.

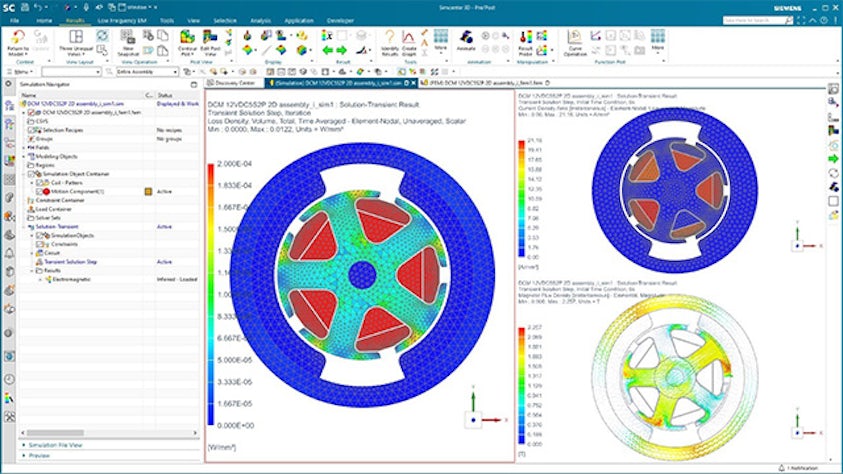

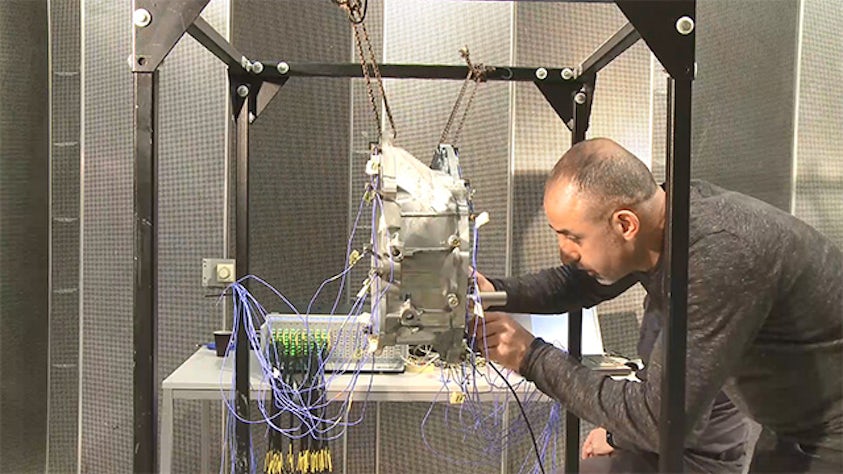

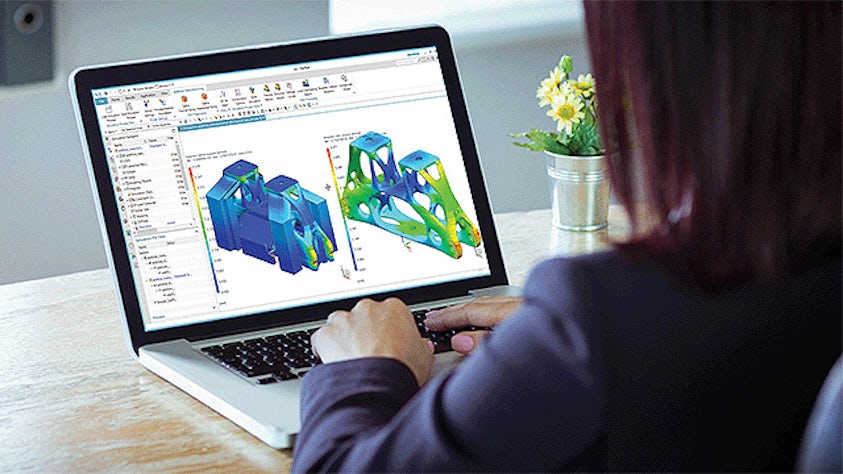

Rozwiązania Simcenter do symulacji mechaniki płynów i termicznej pozwalają wirtualnie prognozować nawet najbardziej złożone zagadnienia związane z mechaniką płynów i przekształcać wynikające z nich spostrzeżenia w innowacje produktowe.