Zwiększ wydajność testów i uzyskuj bardziej wiarygodne wyniki. Pakiet oprogramowania Simcenter Testlab jest bezproblemowo zintegrowany z systemami sprzętowymi do pozyskiwania danych Simcenter SCADAS i może być przyszłościową inwestycją lub bardziej elastycznym i skalowalnym rozwiązaniem czasowym, aby odpowiedzieć na wyzwania inżynierii osiągów. Obejmuje szeroki zakres funkcji testowania używanych przez inżynierów zajmujących się hałasem, drganiami oraz trwałością.

Zwiększ produktywność dzięki wbudowanym przepływom informacji

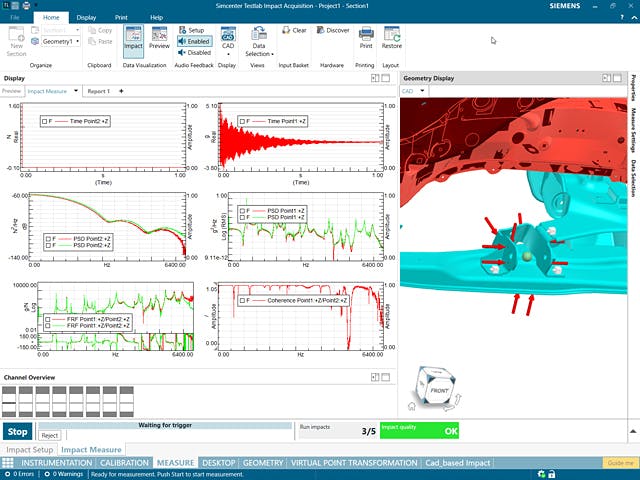

Dzięki wyjątkowemu interfejsowi opartemu na przepływach informacji oprogramowanie Simcenter Testlab wyznacza nowe standardy w zakresie łatwości użytkowania, produktywności i spójności danych. Oprogramowanie prowadzi użytkownika przez kolejne etapy kampanii testowania, sugerując optymalne ustawienia pomiarów i analiz. Bezproblemowe udostępnianie danych między różnymi aplikacjami zapewnia ogromny wzrost wydajności, a wbudowane funkcje analiz podczas pozyskiwania danych przyspieszają proces testowania i gwarantują optymalną jakość danych.

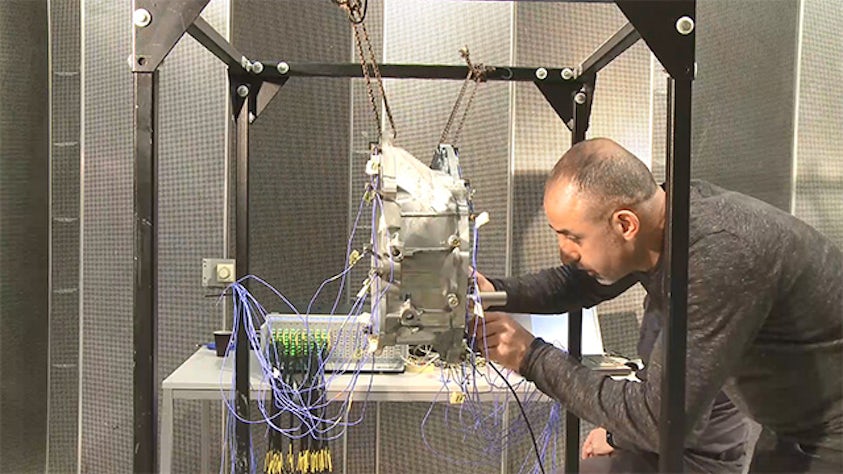

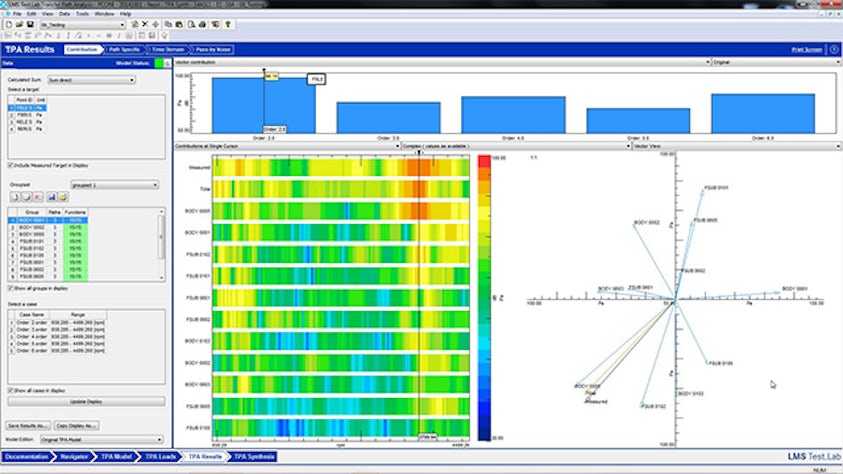

Przejdź prosto do źródła problemów związanych z hałasem i drganiami

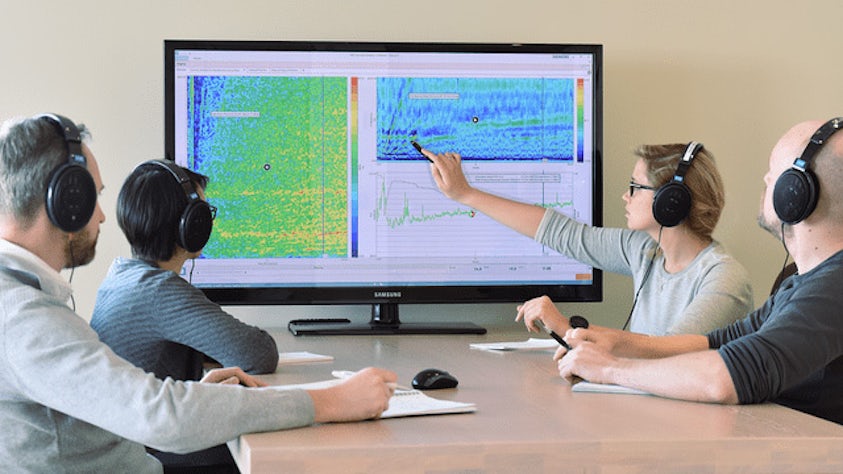

Oprogramowanie Simcenter Testlab prowadzi użytkowników bezpośrednio do źródła problemu za pomocą wszechstronnych możliwości analiz. Umożliwia zespołom testowym skuteczne rozwiązywanie problemów w projekcie oraz identyfikację ich głównych przyczyn bezpośrednio u źródła. Obsługuje łatwe do przeprowadzenia analizy warunkowe, pozwalające szybko ocenić możliwe poprawki oraz rozwiązać problem skutecznie, ekonomicznie i szybko.

Wykorzystaj potencjał w zmieniającym się środowisku testowania

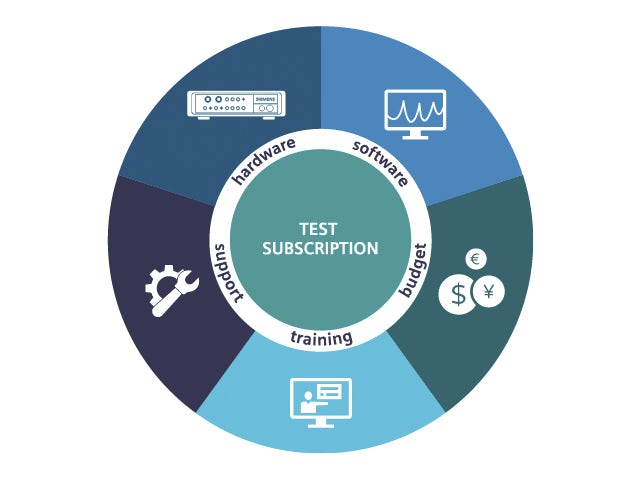

Oprogramowanie Simcenter Testlab jest używane do testowania istniejących komponentów i porównywania konkurencyjnych produktów, dostarczając danych na wczesnych etapach procesu symulacji. Zapewnia również informacje o obciążeniach i informacje zwrotne do aktualizacji modeli wirtualnych. Jest systematycznie używane do tworzenia opartych na testach modeli komponentów i podzespołów, które są zbyt złożone, aby modelować je wirtualnie. Łatwe do zintegrowania z oprogramowaniem Simcenter Amesim oprogramowanie Simcenter Testlab zapewnia niezbędne funkcje zapewniające wydajność i realizm wirtualnej symulacji. Opcje licencjonowania Simcenter Testlab zapewniają elastyczność potrzebną do zwiększenia produktywności dzięki możliwościom zakupu, rocznej lub dłuższej subskrypcji i skalowania według rzeczywistych potrzeb poprzez licencjonowanie oparte na wartości.

Zwiększ wydajność testów i ulepsz innowacje produktowe, korzystając z Simcenter Testlab

Dowiedz się, jak zwiększyć wydajność oraz ulepszyć innowacje produktowe, jednocześnie rozwiązując współczesne wyzwania inżynierskie dzięki wykorzystaniu Simcenter Testlab – oprogramowania do zbierania danych, analizy oraz modelowania.