Dlaczego warto wybrać rozwiązanie Simcenter?

Podwój swoją produktywność dzięki naszym narzędziom światowej klasy, opracowując innowacje przy użyciu rozwiązania Simcenter.

Modelowanie złożoności

Wprowadzanie innowacji to złożona kwestia. Nasze rozwiązanie pozwoli przewidywać zachowanie produktu, zwiększyć dokładność i weryfikować projekty na wczesnym etapie procesu rozwoju. Wykorzystaj inżynierię systemów na podstawie osiągów, aby uzyskać wgląd w cały cykl życia produktu, od koncepcji komponentu do końcowego zastosowania.

Zbadanie dostępnych możliwości

Eksploruj całą przestrzeń projektową przy użyciu złożonych modeli. Oszczędzaj czas i uzyskaj wgląd w cyfrową wersję produktu, zanim wybierzesz ostateczny projekt. Odkrywaj nowe konstrukcje, optymalizuj działanie i szybciej poprawiaj niezawodność projektu.

Szybsze działania

Wykorzystaj inżynierię opartą na sztucznej inteligencji, aby szybko reagować na zmiany preferencji klientów. Korzystaj ze skalowalnych procesów opartych na chmurze i najnowszych zautomatyzowanych przepływów informacji.

integracja procesów.

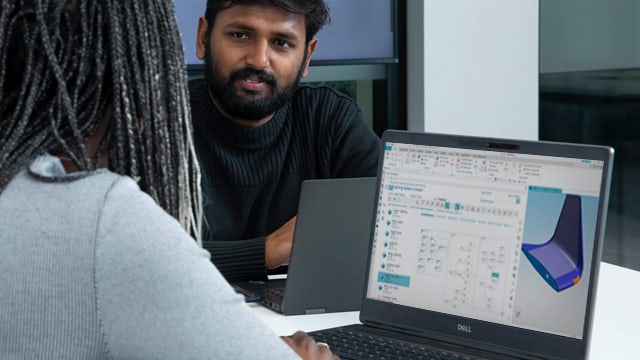

Połącz wszystkie procesy. Połącz wszystkie procesy i zespoły pracujące nawet w najbardziej złożonych środowiskach programistycznych. Zrównoważ osiągi i zagwarantuj identyfikowalność dzięki wątkowi cyfrowemu, umożliwiającemu kompleksową integrację informacji, od modeli symulacji po dane produktu.

Rozwiązania do testowania i symulacji

Inżynieria osiągów wymaga dokładnego prognozowania, aby zapewnić, że produkt spełni pokładane w nim oczekiwania. Przekształć złożoność produktu w przewagę konkurencyjną dzięki rozwiązaniom Simcenter, które umożliwiają zespołom inżynieryjnym przesuwanie granic, rozwiązywanie najtrudniejszych problemów i szybsze wprowadzanie innowacji na rynek.