D-CUBED COMPONENTS

D-Cubed Assembly Engineering Manager

Perform high-accuracy motion simulation in your CAD/CAM/CAE applications with D-Cubed AEM to verify the function of virtual assemblies and mechanisms.

Why D-Cubed AEM?

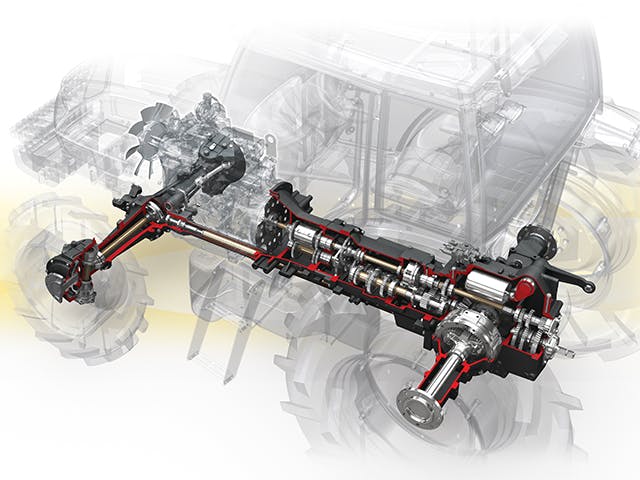

Save time and costs by verifying the function of virtual assemblies and mechanisms, reducing both design errors and the need to produce expensive physical prototypes. D-Cubed Assembly Engineering Manager (AEM) enables software applications to prototype the motion of assemblies and mechanisms more realistically, and accurately predict how parts interact as they collide and transmit motion. AEM takes account of the mass properties of parts and the effects of external forces and mechanical devices, such as motors.

Direct interaction with the geometric model with little or no model preparation means that end-users do not need to be motion simulation experts.

Available as a software component, this motion simulation technology is integrated at the core of a geometric modeling application, providing end-users with motion simulation tools without the need for expensive, complex and less well-integrated motion simulation modules.

See what's included

High accuracy

Automatically compute accurate 3D contacts between all permutations of points, edges and faces of any geometric type, including complex free-form geometry. AEM accuracy satisfies the rigorous demands of the engineering design process.

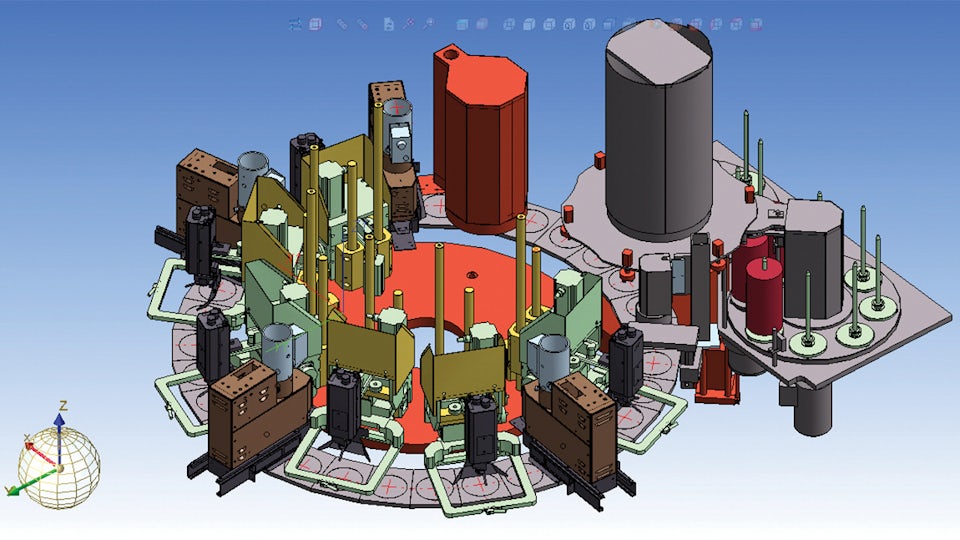

Interactive performance

Investigate the function of a mechanism or explore physical assembly/disassembly processes by by dragging constituent parts in the 3D modeling environment. D-Cubed AEM provides immediate feedback of simulation results to deliver interactive performance.

Motion simulation

Simulate the motion of assemblies and mechanisms with a high degree of realism. Simulations can take account of gravity and a range of forces and devices, such as torques, linear and torsional springs, linear and rotary motors and conveyors.

Assembly parts can be selected and moved interactively during a simulation, while the values of forces are updated, making it possible to assess how the quantitative interaction of forces affects the behavior of a mechanism.

ISD Software

D-Cubed AEM motion simulation software enables CAD/CAM developer to rapidly respond to customer needs

Firma:ISD Software

Lokalizacja:Dortmund, Germany

Siemens Software:PLM Open

Stay connected with PLM Components

Read the blog

Gain new perspectives on PLM Components and the PLM market in general.