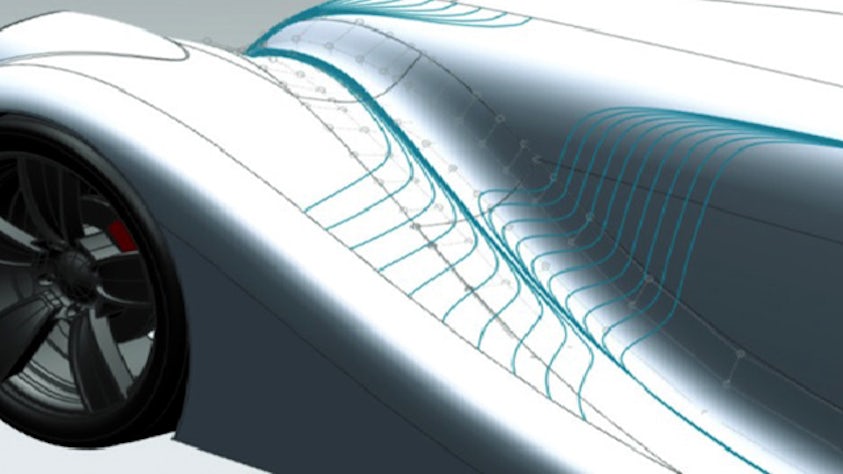

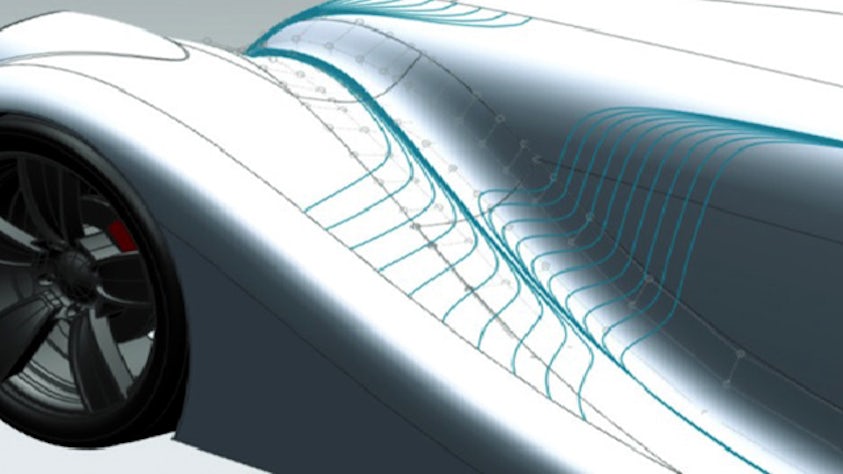

Evaluate the analytical and visual quality of complex shapes with the real-time analysis functions of NX. The real-time graphical displays accelerate evaluation and help guide modifications to improve shape quality.

Start designing today with a free trial of NX CAD, a leading product design solution. Learn how to develop high-quality products by using the high-performance design capabilities of NX. No installation is needed, so you can start designing in minutes.

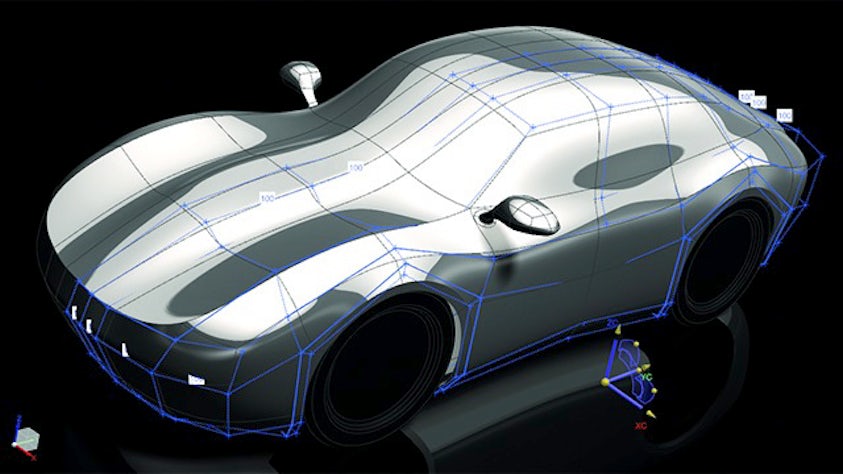

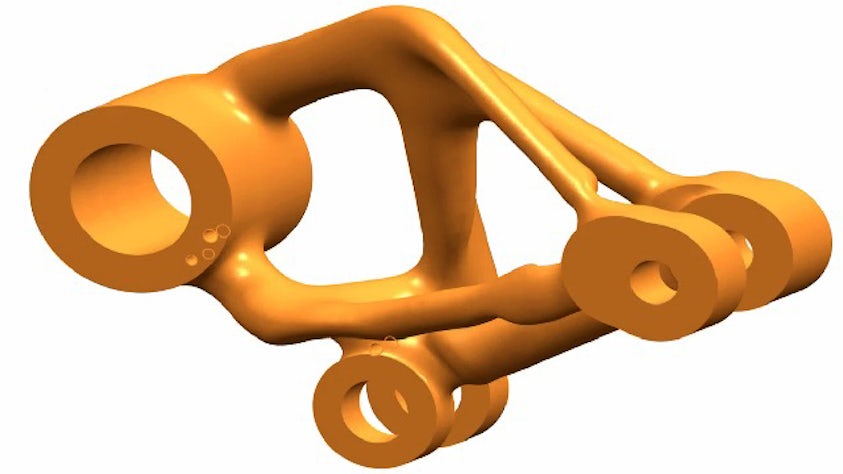

Get a large set of freeform design tools that are useful in all product development disciplines and processes, from concept to manufacturing. Use capabilities for creating solid models using loft, sweep and mesh techniques, surface trimming and extension, surface transitions and advanced filleting.

Evaluate the analytical and visual quality of complex shapes with the real-time analysis functions of NX. The real-time graphical displays accelerate evaluation and help guide modifications to improve shape quality.

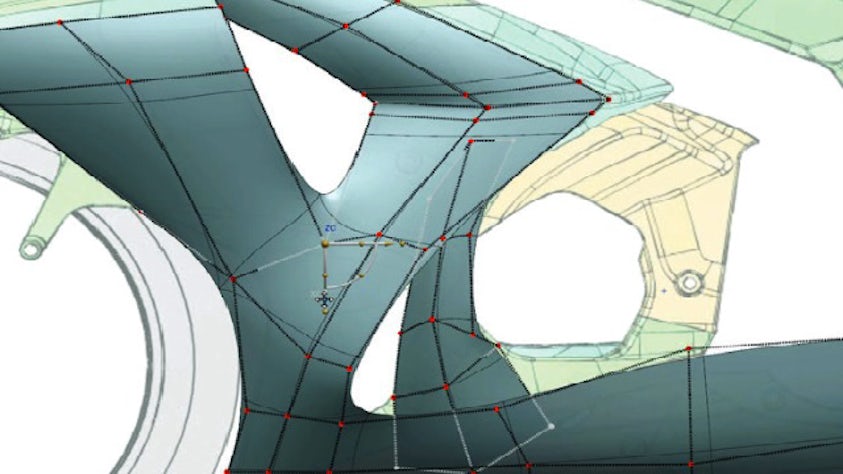

Use advanced functions to extend the freeform toolset to include synchronous sculpting of surfaces and solids with unique history-based class A methods. For exterior and interior class A surfaces, use pole manipulation and surface alignment tools to get full control and real-time analysis of surface quality.

Develop freeform designs using any combination of modeling techniques from a broad toolset with NX hybrid modeling.

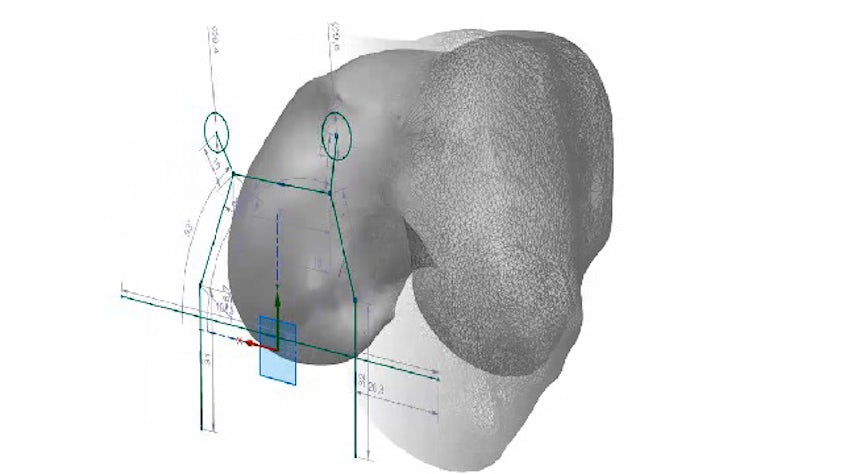

Bring scanned data in as facets—no need to map surfaces, create solids or do any manual shape creation. Build supports for 3D printing, creating molds based on the shape, and perform other operations with CAD data. Easily reverse engineer a product design from a 3D scan.

Combine facets, surface and solids in one model without converting data by using the first technology of its kind, Convergent Modeling. It allows facet data to now be an equal part of the design process.

Easily import and optimize scanned data. NX directly imports polygon facet data acquired by scanning physical objects. It allows you to bring the scanned data in as facets, so there's no need to map surfaces, create solids or do any other manual shape creation. You can easily scan your parts into CAD and immediately begin building supports for 3D printing.

Join us to learn how to use a next-generation solution to address the challenges in the consumer goods industry, such as collaboration, silos and lot sizes of one.

Firma:Callaway Golf

Lokalizacja:California, USA

Siemens Software:NX