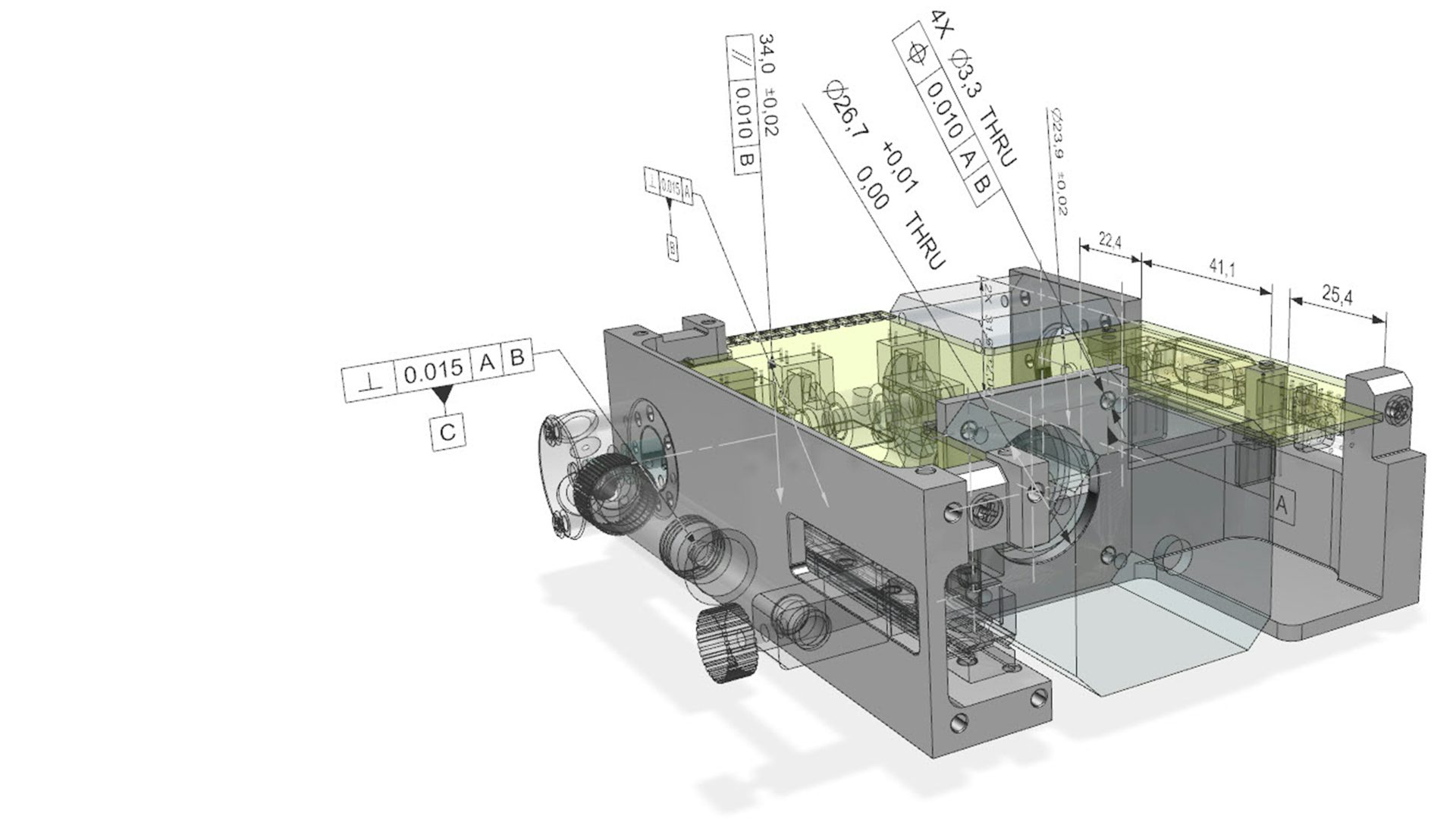

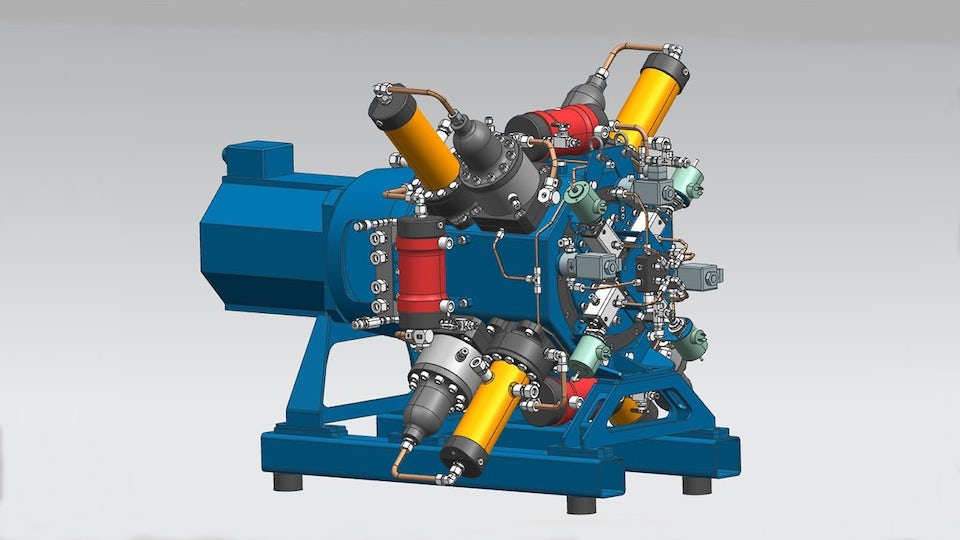

Eliminate the need for 2D drawings while also ensuring the final product complies with its engineering specifications. With NX, product teams can capture and share engineering requirements within the 3D model, thereby permitting full use of the design intent.

People are familiar with 2D drawings and use them to define a finished product. 2D drawings contain standard symbology that is universally understood and interpreted. However, in some cases, the existence of multiple, redundant data required to define a manufactured part can lead to deviations in the final 3D form. Interpretation errors, duplication errors or revision inconsistencies can contribute to costly mistakes that quickly translate into lower quality and productivity.

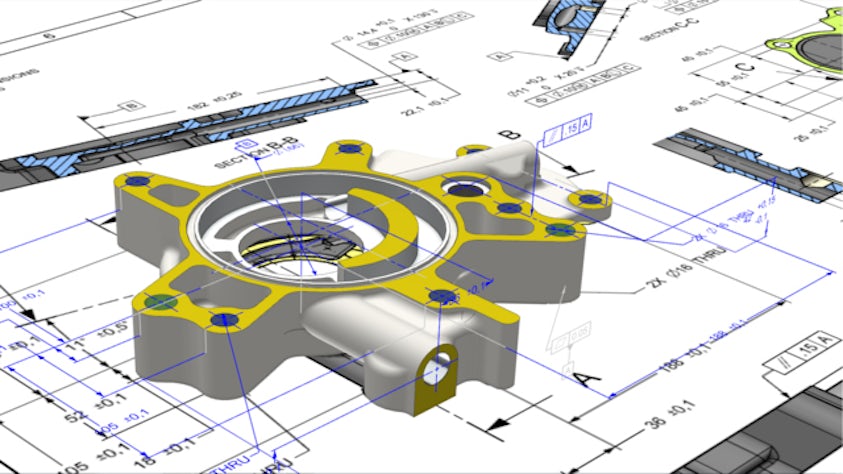

Geometric dimensioning and tolerancing (GDT) is an essential component of complete part definition. It affects most areas of product realization including design, tooling, production and inspection. Apply GDT to 2D part views and 3D models respectively. Use NX CAD to apply GDT symbols to 2D part views and 3D models.

The use of 2D drawings to communicate downstream production requirements adds an unnecessary burden to the product development cycle. A simple change in the product definition requires updated 3D digital data and necessitates numerous engineering changes to all 2D documentation associated with the product. Since it takes time to maintain this documentation, the lifecycle for implementing a product change grows with the extent of its associated 2D data.