Opracowywanie lepszych planów procesów produkcji

Twórz i zarządzaj listami materiałowymi produkcji (MBOM) i listami procesów (BOP), by rejestrować „co należy zrobić” i „jak należy to zrobić”, generuj instrukcje pracy dla hali produkcyjnej, przeprowadzaj szczegółowe analizy czasu pracy, równoważ linie produkcyjne i wykonuj wiele innych działań, zapewniając jednocześnie ścisłą współpracę między zespołami inżynieryjnymi, produkcyjnymi i wykonawczymi.

BSH Home Appliance

Oprogramowanie Tecnomatix i Teamcenter Easy Plan pomagają producentom łatwiej osiągać cele w zakresie wydajności produkcji oraz biznesowe.

Leveraging an open, web-based, easy-to-use solution to standardize process planning across plants

Firma:BSH Home Appliances

Branża:Produkty konsumenckie i handel detaliczny

Lokalizacja:Munich, Germany

Siemens Software:Teamcenter, Tecnomatix

Oprogramowanie Teamcenter Easy Plan do planowania montażu

Easy Plan to ukierunkowane na zadania rozwiązanie internetowe do planowania procesów produkcji.

Obejrzyj film z demonstracją działania i dowiedz się więcej.

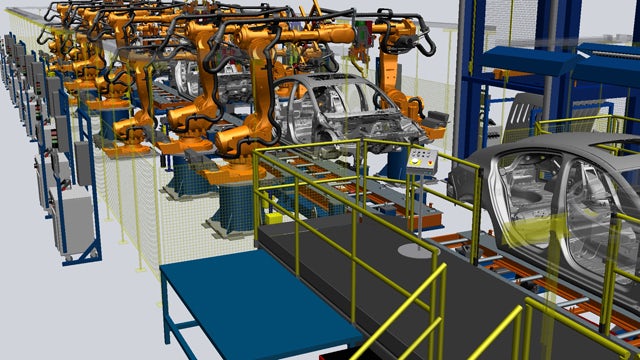

Poznaj produkty do planowania procesów produkcji

Efektywniej wykonuj czynności związane z produkcją części, planowaniem montażu produktu i planami koncepcyjnymi linii produkcyjnych dzięki kompleksowemu zarządzaniu danymi i współpracy przy użyciu rodziny produktów do planowania procesów produkcji.