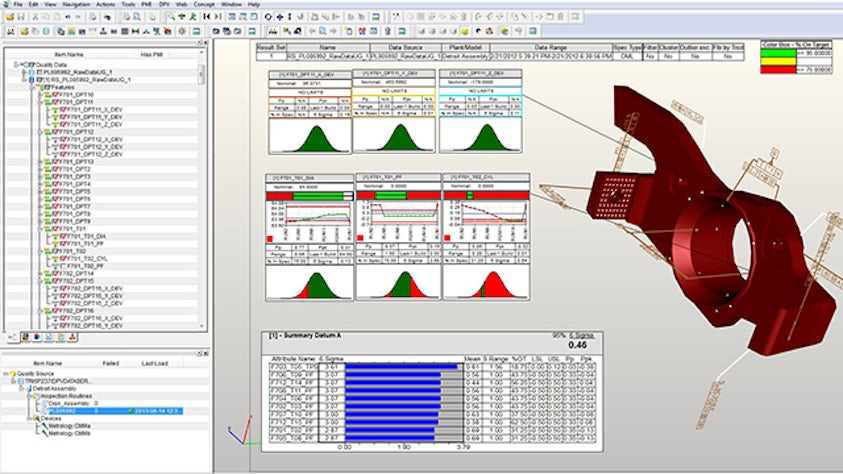

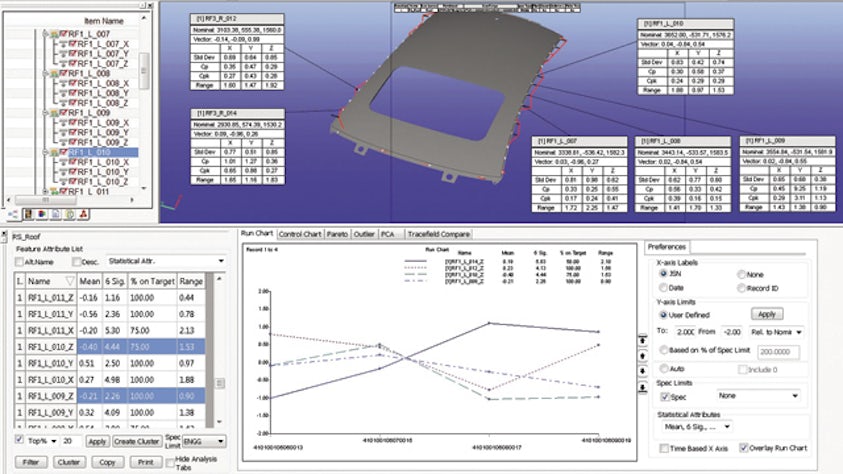

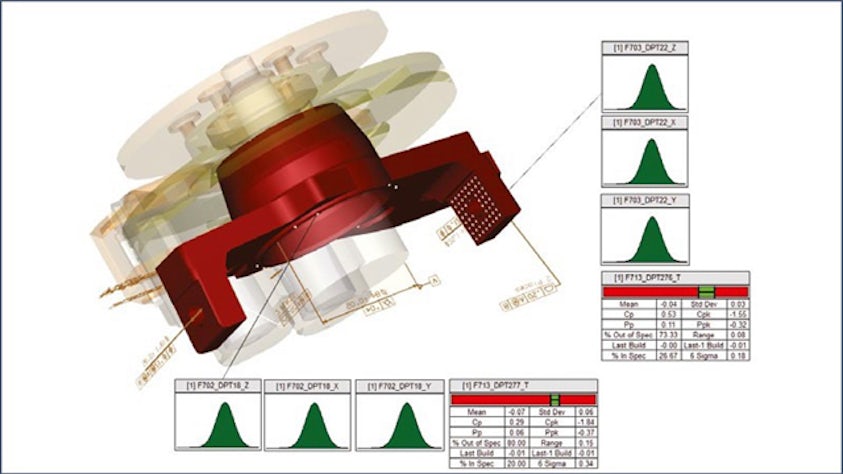

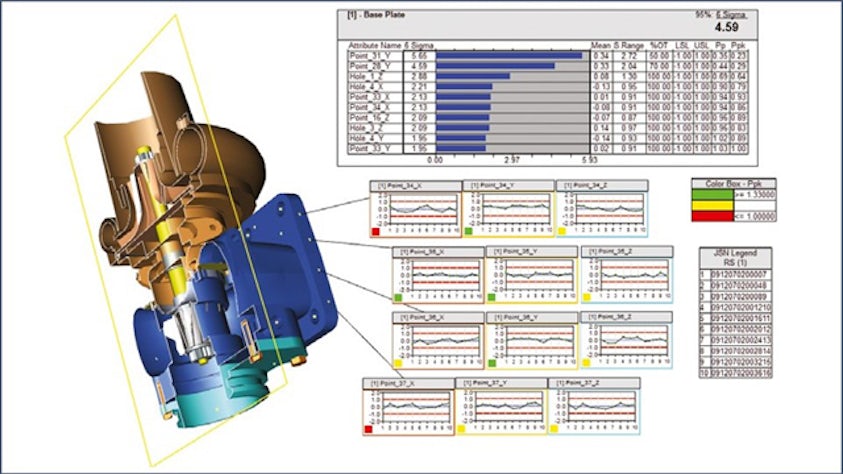

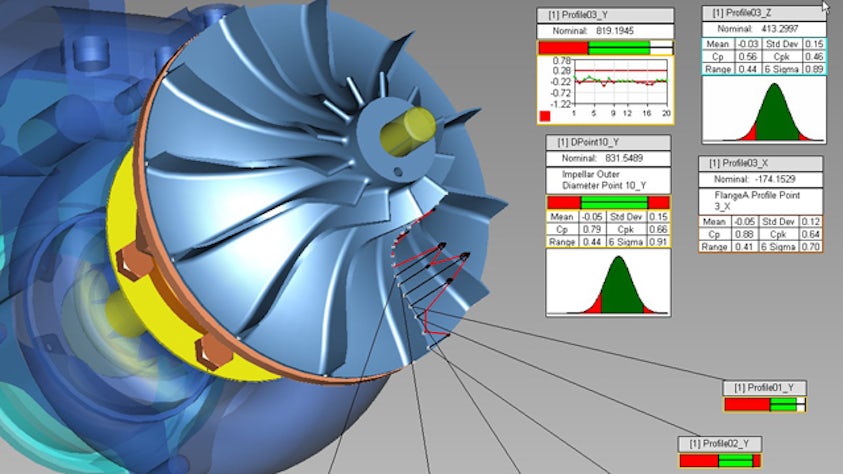

Zintegruj parametry jakości wymiarów w ramach projektowania produktu i procesu planowania produkcji, aby uniknąć kosztownych problemów z jakością produktu:

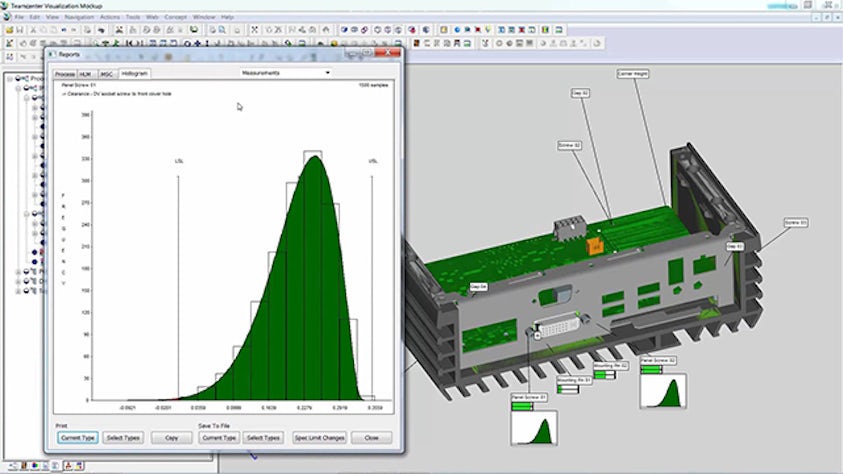

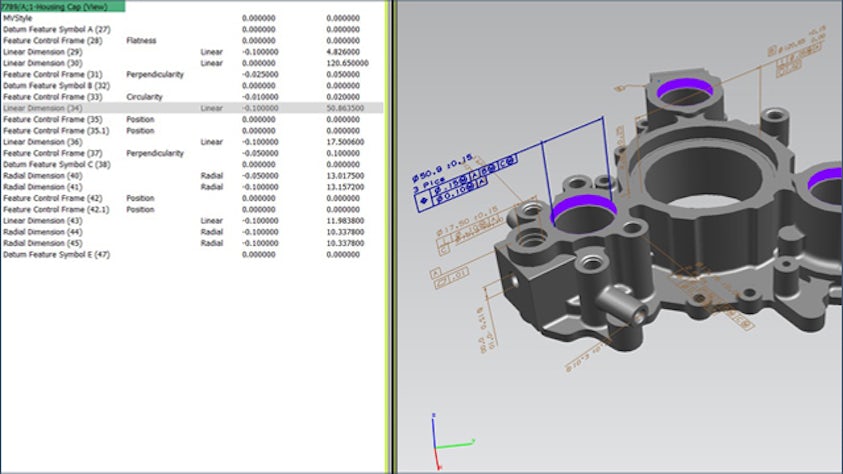

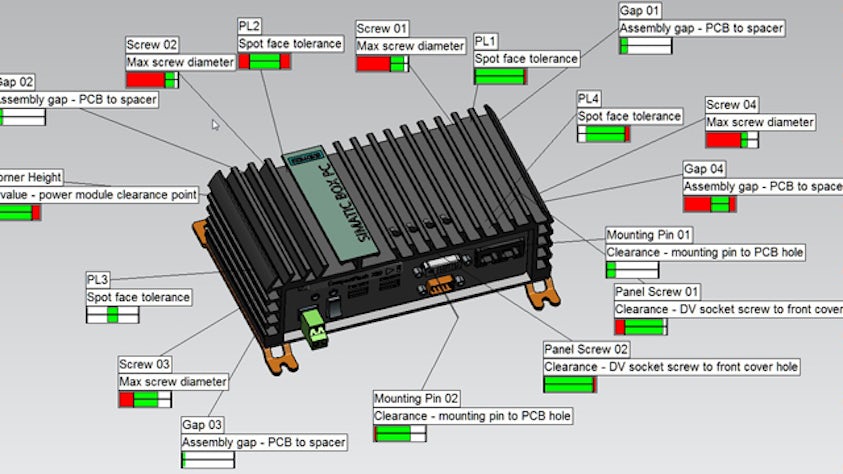

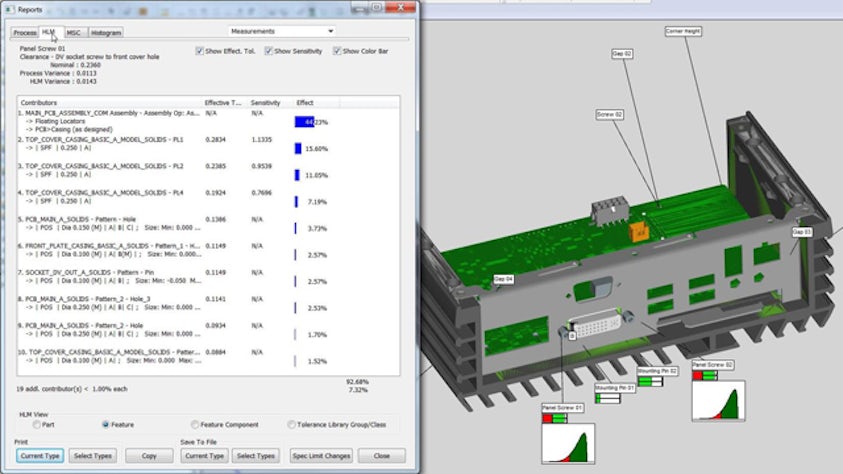

- Zapewnij wysoką jakość produktów w trakcie ich wytwarzania dzięki udostępnianiu informacji na temat wpływu zmienności wymiarów przed przekazaniem projektu do produkcji

- Analizuj wpływ procesów produkcji na cechy projektowe i tolerancje, określając źródła i zakresy zmienności wymiarów w celu poprawienia jakości produkcji i wyeliminowania kosztów