Dlaczego warto korzystać z oprogramowania Tecnomatix?

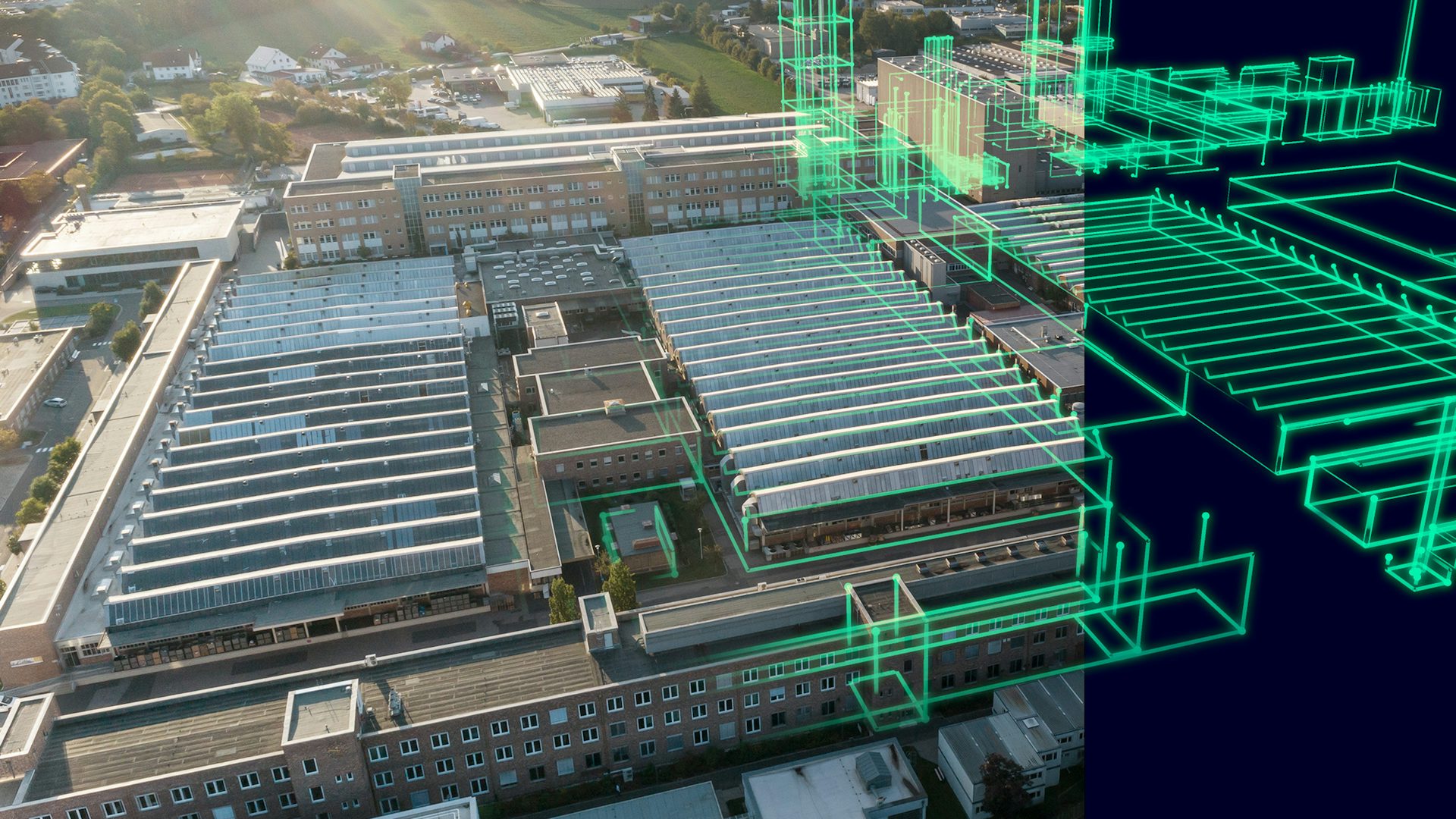

Tworzenie cyfrowego bliźniaka

Modeluj, symuluj i optymalizuj kompleksowego cyfrowego bliźniaka procesów produkcji, obejmującego roboty, automatyzację, systemy transportu materiałów i ludzi, aby poprawić wyniki przedsiębiorstwa.

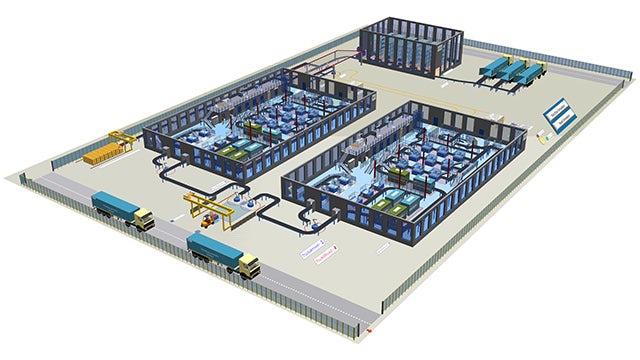

Większa elastyczność

Wykorzystaj symulację i optymalizację zautomatyzowanych lub ręcznych procesów produkcji, aby oceniać i wdrażać zaawansowane techniki produkcji, sprzęt i procesy pozwalające zwiększyć elastyczność produkcji.

Szybsze wprowadzanie innowacji

Korzystaj z realistycznego i immersyjnego środowiska o wysokiej wierności oferującego oparte na fizyce narzędzia do modelowania, symulacji i optymalizacji, aby przyspieszyć wprowadzania innowacji.

Produkcja uwzględniająca potrzeby ludzi

Co pozwala nam dotrzeć na dno oceanu i w przestrzeń kosmiczną? Co zapewnia nam bezpieczeństwo i łączność? Produkcja uwzględniająca potrzeby ludzi.

Produkcja uwzględniająca potrzeby ludzi już dziś pomaga przekształcić jutrzejsze innowacje w dzisiejsze kreatywne produkty. Dzięki zastosowaniu przełomowych technologii, takich jak zaawansowana robotyka i sztuczna inteligencja, samoorganizujące się fabryki stają się rzeczywistością. Zajrzyj w przyszłość produkcji.

Poznaj możliwości oprogramowania Tecnomatix

Wykorzystaj cyfrową produkcję, aby usprawnić działanie przedsiębiorstwa i wprowadzić je w przyszłość.

Poznaj aktualności blogu poświęconym oprogramowaniu Tecnomatix

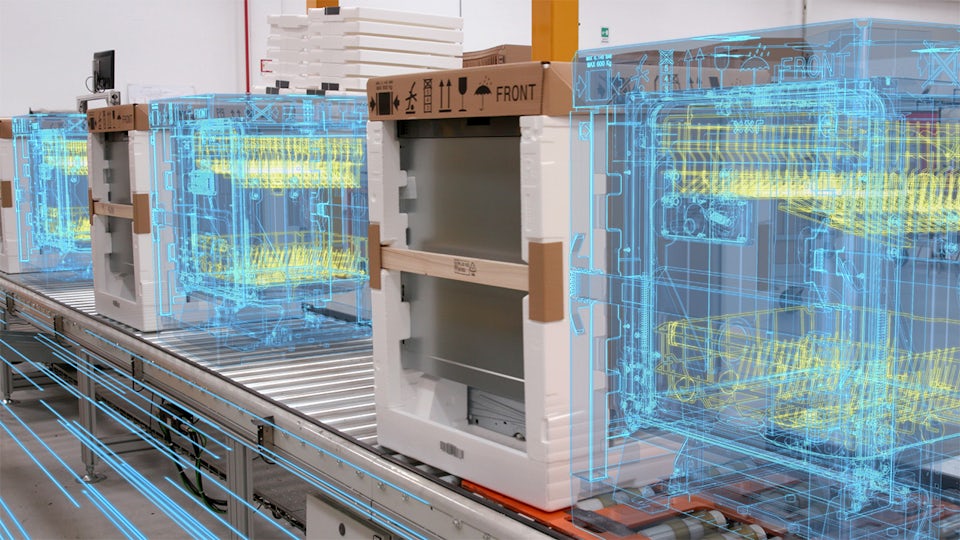

Electrolux

Teamcenter, Simcenter and Tecnomatix help reduce development time by 20 to 30 percent

Firma:Electrolux

Branża:Produkty konsumenckie i handel detaliczny

Lokalizacja:Stockholm, Sweden

Siemens Software:Simcenter 3D Solutions, Teamcenter, Tecnomatix

Poznaj grupy produktów oprogramowania Tecnomatix

Wykorzystaj w pełni możliwości procesów produkcji i wyposażenia dzięki oprogramowaniu do wirtualizacji produkcji.