Połączone procesy wytwarzania przynoszą korzyści biznesowe

Funkcje planowania procesu produkcji i zarządzania danymi w rozwiązaniu Teamcenter umożliwiają szybsze rozpoczęcie wytwarzania produktu. Zapewnij błyskawiczną i bezpieczną współpracę, aby zoptymalizować produkcję i montaż części. Wydajniej wykonuj wszystkie powiązane działania dzięki wątkowi cyfrowemu, obejmującemu całe przedsiębiorstwo i zakłady produkcyjne.

Zarządzanie procesami produkcji w chmurze

Rozwiązanie do zarządzania procesem produkcji w modelu SaaS jest dostępne w chmurze, a zarządzaniem nim zajmują się eksperci firmy Siemens. Zacznij pracę od razu, korzystając ze wstępnie skonfigurowanych najlepszych praktyk. Uzyskaj ciągłość informacji dotyczących produkcji dzięki bezpiecznej wymianie danych i widoczności procesu. Zapewnij sprawną komunikację między projektantami, inżynierami produkcji, planistami, użytkownikami w hali produkcyjnej, partnerami i dostawcami, konstruktorami linii, studiami projektowymi itp.

Łatwe planowanie procesów produkcyjnych i zarządzanie nimi

Twórz dane produkcyjnych list materiałowych (MBOM) i list procesów (BOP), aby lepiej zrozumieć, co i jak ma zostać wytworzone. Oprogramowanie Teamcenter zintegrowane z rozwiązaniami do wirtualizacji produkcji firmy Siemens ułatwia współpracę między projektowaniem, wytwarzaniem i realizacją. W ten sposób można ponownie wykorzystywać procesy montażu w zakładach produkcyjnych, tworzyć i udostępniać instrukcje pracy w hali produkcyjnej, przeprowadzać analizy czasu, równoważyć linię itp.

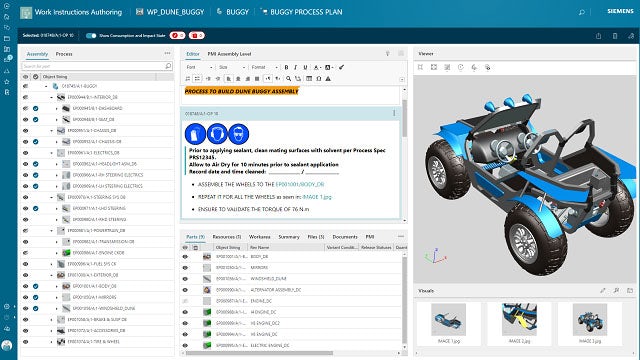

Twórz i udostępniaj elektroniczne instrukcje pracy

Twórz kompleksowe instrukcje pracy, aby zapewnić większą przejrzystość procedur w hali produkcyjnej. Dostarczaj najbardziej aktualne informacje i jednoznacznie określaj etapy listy procesów za pomocą narzędzi do wizualizacji 2D i 3D oraz technologii AR. Dokumentacja procesu jest automatycznie aktualizowana przy użyciu funkcji zarządzania wersjami, dzięki czemu można szybko i łatwo reagować na zmiany, zarówno przed rozpoczęciem produkcji, jak i w jej trakcie.

Tworzenie i obsługa listy procesów (BOP)

Twórz procesy i operacje w ramach listy procesów BOP, aby określić sekwencję kroków w planach montażu. Przypisuj odpowiednie części i zespoły z listy MBOM do procesów, określając wymagane narzędzia i zasoby z listy wyposażenia (BOE) lub za pośrednictwem biblioteki sklasyfikowanych obiektów. Usprawnij wprowadzanie zmian opracowanych przez inżynierów produktu na liście procesów BOP, korzystając z narzędzi do sprawdzania odpowiedzialności, aby zsynchronizować listy materiałowe projektu i produkcji.

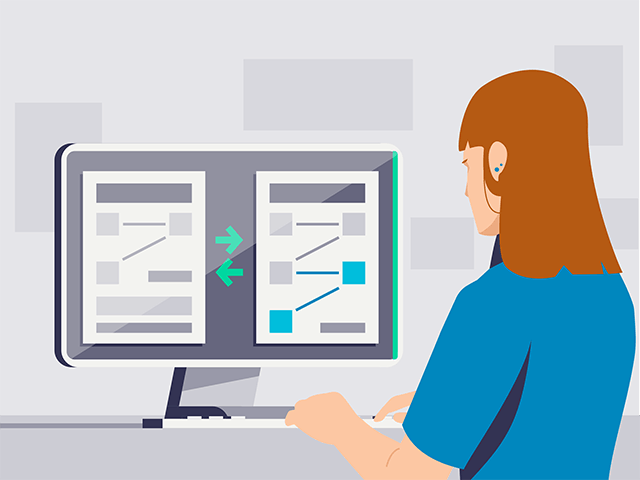

Łatwe uzgadnianie list materiałowych BOM projektu i produkcji

Szybko aktualizuj plany procesów montażu z uwzględnieniem zmian projektowych przy użyciu zintegrowanej platformy rozwoju produktu i procesów w rozwiązaniu Teamcenter. Narzędzia do kontroli odpowiedzialności za listę materiałową BOM pomagają inżynierom produktów i produkcji szybko wizualizować i weryfikować wpływ wszelkich zmian wprowadzanych w produkcie i procesach. Pozwala to uniknąć kosztownej identyfikacji problemów na późnym etapie, po rozpoczęciu produkcji.

Szacowanie czasu realizacji procesów i równoważenie linii

Rozwiązania do zarządzania czasem i równoważenia linii zapewniają wgląd zarówno w działania procesu produkcji tworzące wartość dodaną, jak i niegenerujące takiej wartości. Analiza czasu wykorzystuje standardy czasu, takie jak MTM, z wbudowaną integracją z rozwiązaniem TiCon. Narzędzie równoważenia linii wyświetla wizualne zestawienia czasu z uwzględnieniem operacji, stacji i operatorów. Optymalizuj plany zgodnie z docelowym czasem Takt, usprawniaj pracę operatorów na linii i oceniaj alternatywne plany.

Optymalizacja planowania wytwarzania części na potrzeby produkcji

Przekształć swój zakład obróbki w operację opartą na danych, korzystając z informacji o projektowaniu produktów i planowaniu montażu dostępnych w jednym systemie. Zoptymalizuj procesy produkcyjne dzięki planowaniu części, sprawnej łączności z halą produkcyjną i bibliotece zasobów produkcyjnych.

Wirtualne zarządzanie zasobami produkcyjnymi

Szybko znajduj potrzebne informacje i efektywnie zarządzaj zasobami produkcyjnymi przy użyciu zaawansowanych funkcji wyszukiwania i pobierania działających w pełnym systemie klasyfikacji. Dostęp do zawierającej wstępnie wczytane dane narzędzia skrawającego biblioteki zasobów produkcyjnych (MRL) można uzyskać bezpośrednio z poziomu oprogramowania NX CAM. Można tworzyć złożenia narzędzi lub importować dane z katalogów dostawców narzędzi.

Łączność z halą produkcyjną

Połącz planowanie i produkcję na jednej platformie. Dostarczaj właściwe dane bezpośrednio do sprzętu produkcyjnego, między innymi do maszyn CNC i CMM oraz robotów. Przesyłaj kompletne plany procesów produkcyjnych w różnych domenach funkcjonalnych. Jasno określaj przedmiot, sposób i miejsce wytwarzania produktów. Upewnij się, że wszyscy uczestnicy procesu wiedzą, jakie zasoby są potrzebne.

Next-generation collaboration with Teamcenter Share

Optimize your production and manufacturing processes with Teamcenter Share, a cloud-based collaboration solution with a seamless connection to Teamcenter Easy Plan software. Extend the reach of manufacturing planning-related data and processes beyond your internal teams to work smarter and accelerate innovation.