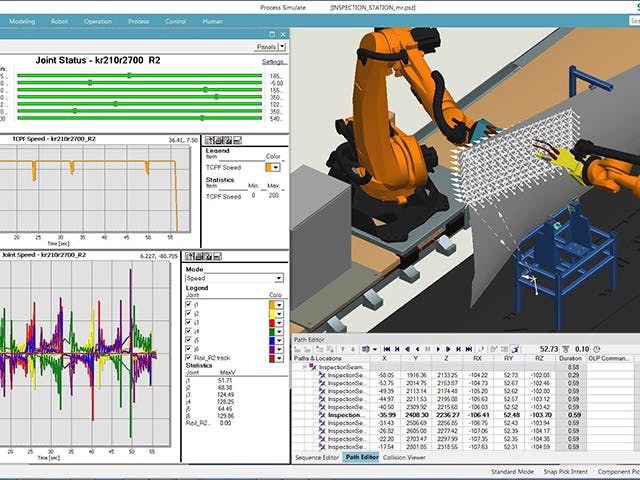

Wirtualne uruchomienie robotyki wykorzystuje środowisko symulacji automatyzacji, a nie fizyczny system robotyki, do testowania zachowania systemu w oparciu o rzeczywiste oprogramowanie sterujące. Wirtualne uruchomienie robotyki odbywa się przed wdrożeniem i uruchomieniem hali produkcyjnej. Jest to jedna z kilku funkcjonalnych możliwości oprogramowania do symulacji robotyki.

Wirtualne uruchomienie robotyki wykorzystuje cyfrowego bliźniaka, który jest interaktywną wirtualną reprezentacją systemu robotyki i otaczającego środowiska produkcyjnego, w celu symulacji planowanej i zaprogramowanej pracy systemu robotyki. Umożliwia inżynierom produkcji programowanie robotyki offline i testowanie jej bez zakłócania bieżących operacji produkcyjnych.

Wirtualne uruchomienie robotyki wykorzystuje środowisko symulacji automatyzacji, a nie fizyczny system robotyki, do testowania zachowania systemu przed wdrożeniem i uruchomieniem na hali produkcyjnej w oparciu o rzeczywiste oprogramowanie sterujące. Jest to jedna z kilku funkcjonalnych możliwości oprogramowania do symulacji robotyki.

Powiązane produkty: Symulacja procesu Tecnomatix