Symulacja systemu to proces eksperymentowania i badania, w jaki sposób zmiany charakterystyki złożonego systemu (lub podsystemu) wpływają na system jako całość.

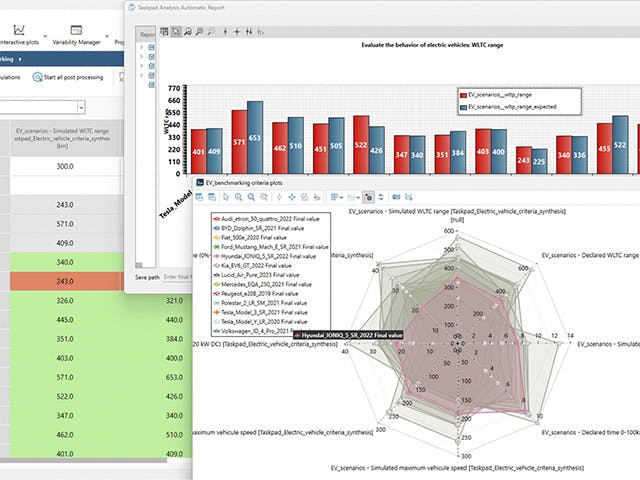

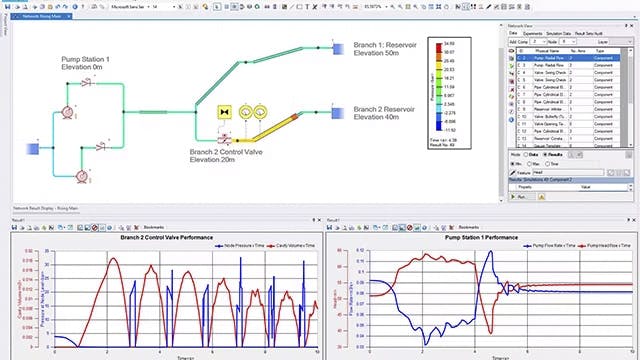

Zaawansowane oprogramowanie symulacyjne wykorzystuje algorytmy matematyczne do przewidywania i ilustrowania wpływu proponowanych zmian w systemie. Symulacja systemu może być wykorzystana podczas projektowania nowego systemu, do odkrycia pierwotnej przyczyny problemów w istniejącym systemie lub do przetestowania dostosowań systemu w celu uzyskania różnych wyników.

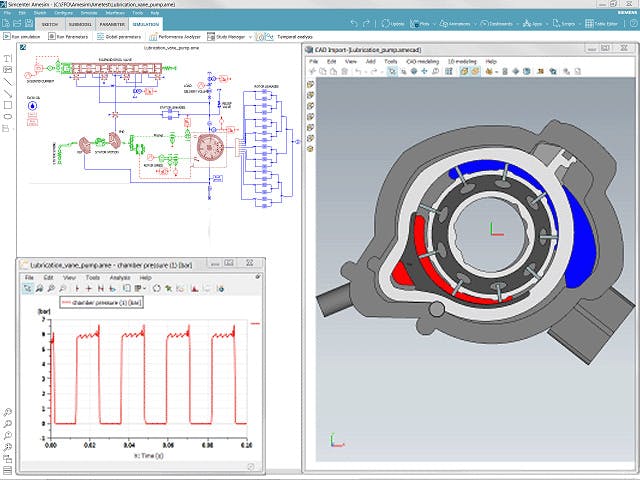

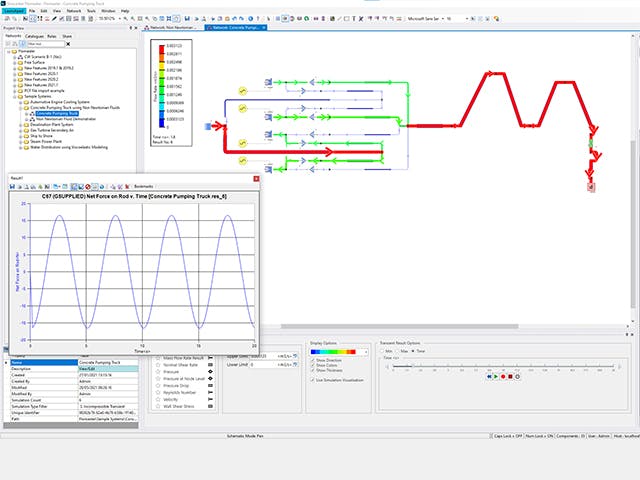

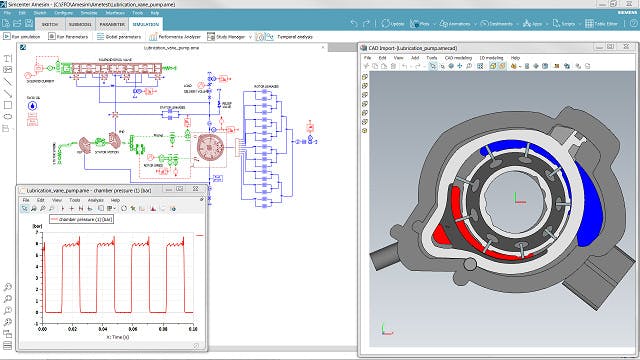

Symulacja systemu umożliwia zespołom inżynierskim wcześniejszą optymalizację systemów wielofizycznych poprzez ocenę interakcji między komponentami mechanicznymi, hydraulicznymi, pneumatycznymi, termicznymi, elektrycznymi i elektronicznymi, zanim pierwszy fizyczny prototyp stanie się dostępny. W kontekście bardziej zautomatyzowanych i zelektryfikowanych produktów symulacja systemu pomaga inżynierom projektantom przewidywać zachowanie złożonych systemów wielofizycznych, znajdować konfiguracje spełniające wymagania dotyczące wydajności i przyspieszać podejmowanie decyzji inżynierskich.

Powiązane produkty: Simcenter Amesim | Simcenter Flomaster | Simcenter System Analyst | Simcenter HEEDS