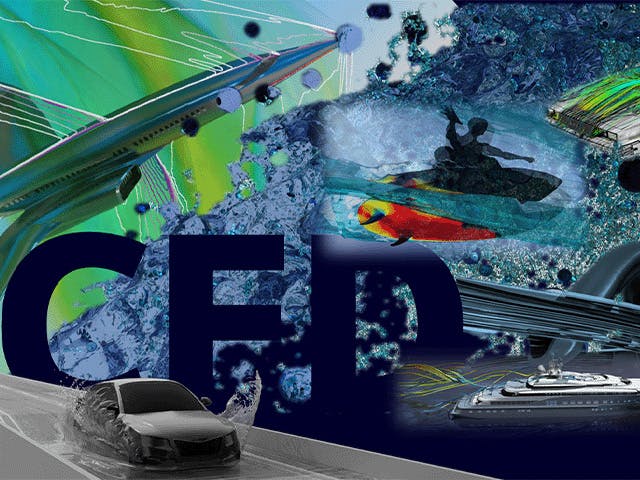

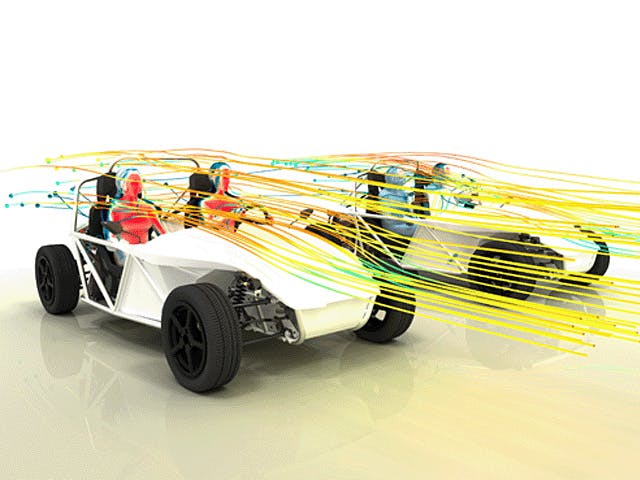

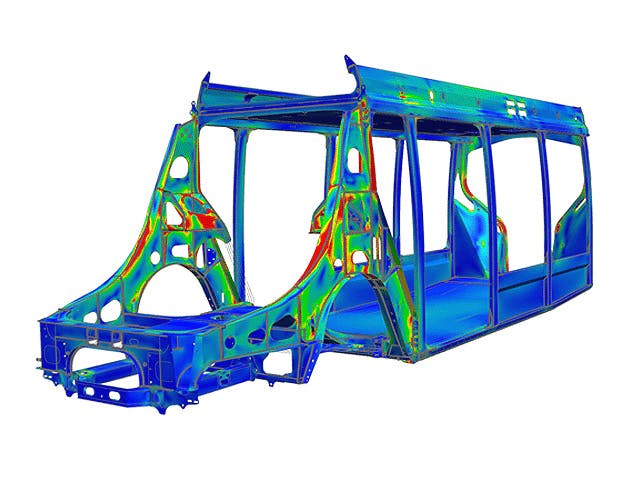

CAE lub inżynieria wspomagana komputerowo to wykorzystanie oprogramowania komputerowego w wielu gałęziach przemysłu do symulacji wydajności opartej na fizyce w celu ulepszenia projektów produktów lub pomocy w rozwiązywaniu problemów inżynieryjnych. Obejmuje to symulację, walidację i optymalizację produktów, procesów i narzędzi produkcyjnych.

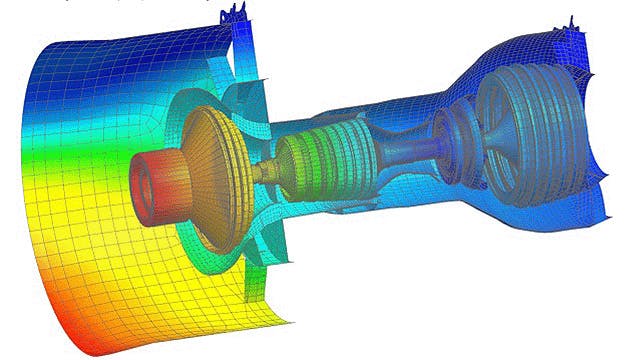

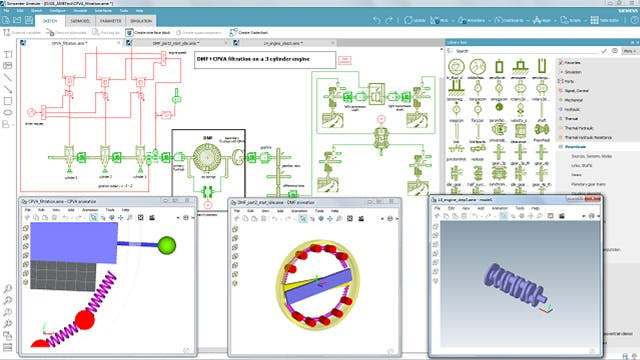

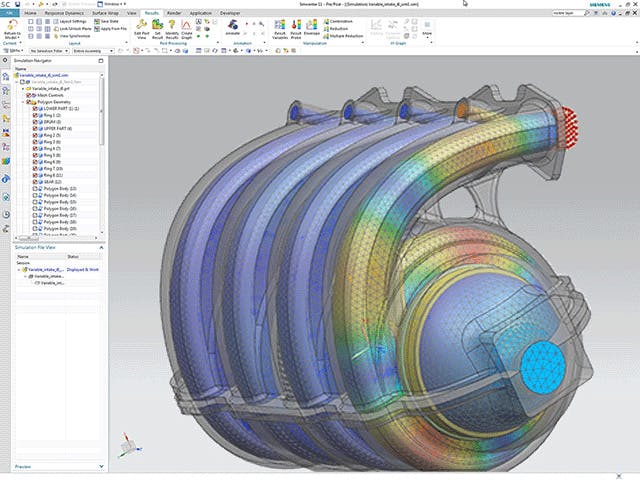

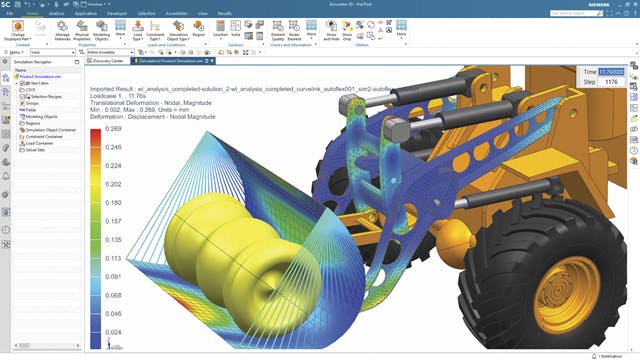

Typowy proces CAE składa się z etapów przetwarzania wstępnego, rozwiązywania i przetwarzania końcowego. W fazie przetwarzania wstępnego inżynierowie modelują geometrię (lub reprezentację systemu) i właściwości fizyczne projektu, a także środowisko, w postaci przyłożonych obciążeń lub wiązań. Następnie model jest rozwiązywany przy użyciu odpowiedniego sformułowania matematycznego fizyki bazowej. W fazie postprocessingu wyniki są przedstawiane inżynierowi do wglądu.

Powiązane produkty: Simcenter 3D | Simcenter Nastran | Simcenter Femap | Simcenter MAGNET | Simcenter E-Machine Design | Simcenter STAR-CCM+ | Simcenter FLOEFD dla NX | Simcenter Flotherm XT | Simcenter Madymo | Simcenter Amesim