Railway manufacturer uses Teamcenter and Tecnomatix to reduce design cycle by 30 percent and double stock utilization

Siemens Digital Industries Software solutions enable Puzhen to improve support for design, process, testing and simulation management projects

CSR Nanjing Puzhen Co., Ltd. (Puzhen)

CSR Nanjing Puzhen Co., Ltd. (Puzhen), which was founded in 1908, is a research and manufacturing enterprise and an integrated service supplier for railway transport of passengers and urban rail transport equipment in China. The firm manufactures urban rail transit vehicles, intercity multiple units, modern tramcars as well as passenger cars and important core parts.

http://www.cccme.org.cn/shop/cccme9769/index.aspx- Headquarters:

- Nanjing, China

- Products:

- Teamcenter, Tecnomatix

- Industry Sector:

- Automotive & transportation

CSR Nanjing Puzhen Co., Ltd. (Puzhen), which was founded in 1908, is a research and manufacturing enterprise and an integrated service supplier for railway transport of passengers and urban rail transport equipment in China. The firm manufactures urban rail transit vehicles, intercity multiple units, modern tramcars as well as passenger cars and important core parts.

As China began to renovate its rail transit lines and expand urban/intercity rail transit transportation in 2004, Puzhen entered a period of tremendous growth. In 2014, the company’s annual sales hit ¥10 billion, up from less than ¥2 billion in 2004. In 2015, Puzhen officially kicked off the mass production of its 200 kilometers per hour (km/h) class intercity high-speed train for the Guangdong province.

In addition to a continued boom in the rail transport equipment manufacturing industry, the rapid growth of Puzhen is also attributable to its persistent efforts in research, development and manufacturing to improve its ability to innovate. Puzhen started to implement lean management early on, and has applied advanced information and digital systems such as computeraided design (CAD), computer-aided manufacturing (CAM), product data management (PDM) and enterprise resource planning (ERP) in the research and development (R&D) and manufacturing processes to facilitate efficient and collaborative integration between design and manufacturing.

In 2013, Puzhen decided to implement two solutions from product lifecycle management (PLM) specialist Siemens Digital Industries Software: Teamcenter® software and the Tecnomatix® portfolio. The objective was to enhance planning, better manage and control design development projects, improve collaboration across design processes, and increase process quality and productivity. Two years into deployment, the company has realized significant achievements in design and manufacturing collaboration throughout the product lifecycle. In addition, it has built a uniform and comprehensive information-based R&D and manufacturing process, greatly enhancing innovative product R&D and manufacturing.

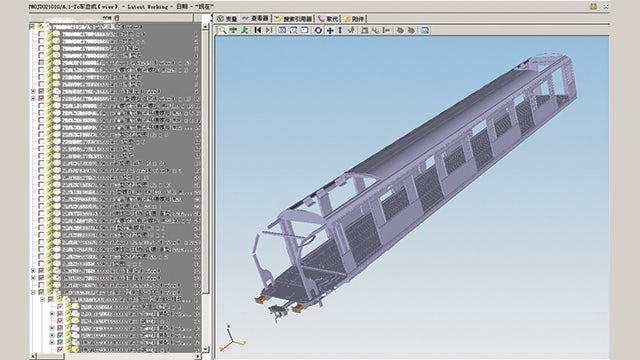

Puzhen uses Teamcenter for lightweight design and process planning based on full 3D models.

Allying with Siemens Digital Industries Software

Puzhen has a tradition of conducting solid technical research and information management. During the past decade, the company worked on the construction of a digital design and manufacturing platform. It adopted 2D and 3D CAD software and simulation analysis software for digital product design, and invested millions in building a PDM system that would enable sharing of design resources. Puzhen built an R&D system and testing platform adapted to its lean management idea. The company developed and implemented a science-based, practicable business information system for strategic planning. Based on PLM and select information technologies, Puzhen has realized integrated innovation in finished vehicles, and mastered core technologies in areas such as network control, aluminum alloy and stainless steel body manufacturing, as well as bogies and brakes.

The problem was that the prior software tools and PDM system needed to be upgraded due to insufficient standardization and lack of application depth. Puzhen’s early PDM system, though lightweight, convenient and sufficient for basic data and process management, was unable to be scaled up to cover other business units, including process and manufacturing. Therefore, Puzhen decided to introduce a more complete and powerful PLM system to help with collaboration and integration, from R&D and design to process planning and manufacturing.

After a long, detailed evaluation and analysis of similar companies and products both at home and abroad – based on technical capabilities, industrial experience, service abilities, costs and other considerations – Puzhen determined that solutions from Siemens Digital Industries Software could best meet its mid- and long-term applications requirements.

Teamcenter is a powerful collaborative product data management (cPDM) solution that has been applied extensively by large and mid-sized manufacturers all over the globe. Teamcenter enables enterprises to accelerate implementation, increase productivity, enhance collaboration both inside and outside of the company, and expand control over the entire product lifecycle process, while its uniform architecture provides enterprises with a complete end-to-end PLM solution.

Tecnomatix is a digital manufacturing system that integrates product R&D and design with process planning, process simulation and verification, and manufacturing execution. The combination of these two solutions is a perfect match for Puzhen to meet its requirements for in depth collaboration in R&D and manufacturing.

In addition to the powerful solutions and functions provided by Teamcenter and Tecnomatix, Puzhen points out that Siemens Digital Industries Software’s extensive experience working with large and mid-sized enterprises, especially those in the rail transport equipment manufacturing industry, as well as the technical service abilities of its implementation and after-sale teams, also played an important role in the decision. Siemens Digital Industries Software has accumulated a wealth of PLM project planning and implementation experience as its solutions have been widely applied in many well known manufacturing enterprises in China and throughout the world. Siemens Digital Industries Software is a significant participant in the global rail transit market with extensive practical engineering knowledge in business process features and information-based planning.

After two years of cooperation, Puzhen points out that, from the start, Siemens Digital Industries Software provided it with comprehensive PLM experience, highly effective technology products and important implementation/consulting services. During the midterm deployment and implementation process, Puzhen notes that Siemens Digital Industries Software helped it realize truly efficient project management and execution.

Puzhen’s design, process and simulation platforms form a closed-loop data process management system.

Building an integrated platform

By deploying Siemens Digital Industries Software’s solutions, Puzhen intended to optimize design and process management, improve R&D efficiency and increase process simulation capabilities in order to meet both the market demand for rapid development and the company’s internal requirement for lean production. To that end, the leadership at Puzhen attached great importance to the implementation of the PLM project, repeatedly discussed the project at the company’s strategic meetings and kept a close eye on project execution. At critical project junctures, the leadership sought debriefings by the implementation team. The leadership required that the PLM project take the company’s business features into full account, thus thoroughly solidifying the management mindset of lean R&D.

With such attention and support from the company’s leadership, Puzhen has successfully motivated the staff to participate across management and technical levels. The implementation of the PLM project was headed by the technical information department, and a full-time project implementation team was formed consisting of key business personnel from the information, design, technology and other departments. The technical information department was tasked with overall control, management and promotion at all stages of implementation, while the design and technology departments mainly focused on assisting with solving business problems and relevant user testing work.

Siemens Digital Industries Software provided guidance and support throughout the process, delivering special insight in key impact areas, including technology, business, knowledge training and team management.

Using collaborative efforts at multiple levels, to date, Puzhen has implemented management projects for design, process, testing and simulation. Currently, the company is extending such projects to manufacturing sites and other disciplines within the organization.

The PLM system has been used to build four major platforms: design, process planning, simulation and testing. In total, 102 projects have gone live, enabling Puzhen to collect and use extensive platform data, improve design quality, significantly reduce design and process planning cycles, and cut down manufacturing and purchasing costs.

Puzhen has used Teamcenter to form a closed-loop information flow that has helped it realize six unifications and a single integration. The company has unified its product design data platform based on project management, R&D process control, the design resource platform (code, standard and interchangeable parts library and template), engineering change platform, file management for the release and storage of electronic drawings, and design simulation and testing verification platform; and Puzhen has integrated its data chain of design, process and production.

The six unifications and single integration have helped Puzhen:

Build major platforms for design, process and simulation, forming closed-loop data process management

Implement design management platform functions for file coding, file review and approval, design resource, file template, project data and electronic filing

Realize lightweight R&D and process planning based on full 3D models

Deliver integrated, platform-based engineering bills of materials (EBOMs), preliminary bills of materials (PBOMs), manufacturing bills of materials (MBOMs), enabling data source consistency and output standardization

Establish a structural assembly process, allowing engineers to directly view and use the design part information (including 3D design data), and to view complete upstream/downstream assembly relationships and sequences, with real-time process design facilitating quick, enlightened decision-making

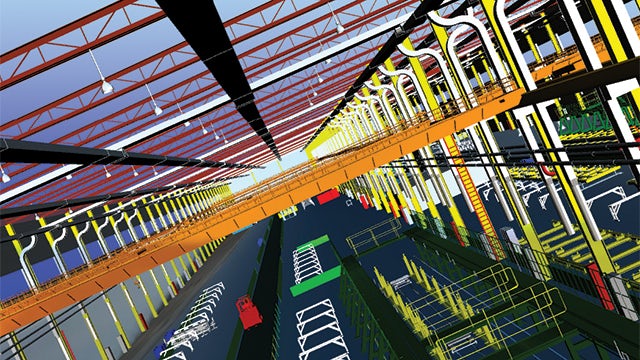

Establish a shop floor simulation layout plan based on virtual reality and simulation technology, enabling the company to model a design or production process of a product in a unified and detailed fashion; utilize fully digital product design, processing, assembly and verification; and simulate the complete product lifecycle

Potential bottlenecks, critical paths and logistics issues are now readily identified, enabling increased production and improved equipment utilization. This notably reduces costs and increases competitiveness. Using the Teamcenter and Tecnomatix combination, Puzhen has shortened the design cycle by 30 percent while doubling stock utilization.

Puzhen’s design platform enables the highly efficient management of functions: file coding, file review and approval, design resource, file templ ate, project data and electronic filing, etc.

Puzhen simulates a 3D digital plant using Tecnomatix.

In the near term

The use of Teamcenter has provided great support for business data management, business process solidification and efficient product design, while enabling the company to build a uniform, standardized data sharing platform outside of the company that facilitates highly efficient business data exchange. For example, the Teamcenter PLM collaborative design platform has made it much easier for business groups and departments to exchange data, eliminating the difficult process of capturing issues that had been discussed during early stages of the project implementation process. Puzhen is particularly impressed with just how easily data can be found.

In the future, Puzhen IT plans to focus on platform construction, information flow, intelligent connection and interaction, smart manufacturing and related resources to build a super BOM platform, open up the entire business process and build a complete digital highway. The company is looking forward to Siemens Digital Industries Software’s recommendations regarding more advanced industrial and technical concepts, new pragmatic solutions and skillful implementation services. Ultimately, Puzhen is expecting to forge an even closer partnership with Siemens PLM Software for sustained, if not breakthrough, productivity gains.