NX and Teamcenter deliver a localized digital platform for shipbuilding that enhances collaboration

Siemens Digital Industries Software enables HUST to facilitate industrialization of scientific research and enhance supply of industry talent

Huazhong University of Science and Technology

The Huazhong University of Science and Technology (HUST) is a public, coeducational research university. As a key national university, HUST is directly affiliated with the Chinese Ministry of Education.

http://www.english.hust.edu.cn/- Headquarters:

- Wuhan, Hubei, China

- Products:

- NX, Teamcenter

The NX and Teamcenter software solutions from Siemens Digital Industries Software not only have powerful modeling and data management capabilities, but they are also quite open, which means they allow secondary development and module customization, thus better supporting localized ship development and design work.

Huazhong University of Science and Technology

Developing talented shipbuilders

Since 2012 the Chinese economy has entered the new normal with a slower growth rate, so it is no surprise that after years of rapid growth its shipbuilding industry is now faced with new challenges and opportunities, commencing a transformational period of proactive exploration and expansion. During this period, China’s 13th Five-Year Plan, there has been a loud call for digital shipbuilding. Therefore, China aims to transform itself from a large shipbuilding power to a strong shipbuilding power, and that will mean accelerating transformational upgrades, innovating more and developing information and green technologies, all of which will play a critical role in quickening the adoption of shipbuilding digitalization. As a result, it will be key to develop a deep supply of talented digital shipbuilding professionals to help China’s shipbuilding industry attain its goals for the 13th Five-year Plan.

On August 28, 2014, the Huazhong University of Science and Technology HUST-Siemens Digital Industries Software Joint Laboratory for Digital Shipbuilding was officially unveiled at the institution’s School of Naval Architecture and Ocean Engineering (NAOE), and Siemens Digital Industries Software gave the school product lifecycle management (PLM) software. As the first laboratory dedicated to the shipbuilding profession built jointly by Siemens Digital Industries Software and a Chinese university, the goal was to cultivate talent for digital shipbuilding, collaboratively develop localized shipbuilding software and expand the industry-university-research cooperation model.

Collaboratively conducting scientific research for digital shipbuilding

When it comes to cultivating high-end talent for the shipbuilding and ocean engineering profession, the School of NAOE at HUST features distinctive subjects and prominent specialties. The school grew out of the department of shipbuilding at Huazhong Institute of Technology, which in 1959 was entrusted by the state authority of coastal defense to set up a major operation in submarine design and manufacturing.

Zhu Jiusi, then secretary of the party committee and vice president of Huazhong Institute of Technology, founded the school. After nearly 60 years of development, the School of NAOE has made great strides in a variety of areas, such as building up the technical training center, cultivating talent, basic research, etc., and won numerous prizes for its outstanding scientific research results, including first and second prizes in the state scientific and technological progress competition, and first prize in the scientific and technological progress competition conducted by the ministry of education.

But why did Siemens Digital Industries Software choose the School of NAOE from among so many domestic universities and colleges that offer courses in the study of ocean engineering and shipbuilding?

First, the School of NAOE has an outstanding track record in areas such as hydrodynamic performance analysis, cutting-edge theories and methods of naval design, engineering structural mechanics performance analysis and optimization, and naval mechatronic control technology, and is earnest about developing and applying digital technology. Second, the School of NAOE, located in Wuhan and adjacent to the Yangtze River, has established close long-term industry-university-research partnerships with two major ship development and design institutes in Wuhan, and is now in need of digital technologies to support collaborative scientific research (and practical teaching) to industrialize the scientific research results. That is the basis for the cooperation between the School of NAOE and Siemens Digital Industries Software.

“The NX and Teamcenter software solutions from Siemens Digital Industries Software not only have powerful modeling and data management capabilities,” says HUST Professor Liu Jingxi, “but they are also quite open, which means they allow secondary development and module customization, thus better supporting localized ship development and design work.”

Since 2014 research and development (R&D) personnel from Siemens Digital Industries Software have been working closely with professors at the School of NAOE, engaging in months of customization R&D in the field of shipbuilding. Based on the design and construction features of Chinese ocean engineering and ship equipment, professors at HUST determine requirements for digital development and research, while researchers from Siemens Digital Industries Software offer functional enhancement and software optimization.

For example, for a certain kind of opening required for a hull structure, engineers from Siemens Digital Industries Software would optimize the opening function accordingly. After adjustment and optimization, the digital shipbuilding software from Siemens Digital Industries Software can be better applied to the digital practices required in the teaching and studying of this subject at the School of NAOE, and it can also better accommodate the process features and needs of Chinese shipbuilders.

According to Liu, in the past two years the joint laboratory has used in-depth teaching and training in addition to the undergraduate curriculum to deliver more than 60 graduates to the shipbuilding industry. Having obtained a relatively comprehensive understanding of digital ship research and development technologies utilizing NX™ software, those graduates are fully familiar with the 3D ship design environment, and can quickly adapt to the digital workflows employed by shipbuilders.

Improving design efficiency and supporting teaching practices

Like airplanes and automobiles, competitiveness in ocean engineering and ship products lies in several aspects, including the R&D cycle, cost, quality and service. In the aerospace and auto industries, major manufacturers around the world leverage digital technologies to reform their organizations. For instance, with digital technologies, a well-known American automotive company shortened the R&D cycle of a new car from 48 to 24 months, and the number of crash tests from hundreds to dozens.

Relatively speaking, digitalization in shipbuilding has been lagging far behind the automotive and aerospace sectors. However, the shipbuilding industry features a more complex product structure and infrastructure, more production management ideas, a higher level of collaboration and a longer product service life. All of which means it is in more urgent need of digital technologies than other sectors, but it also has greater potential.

The setup of the HUST-Siemens Digital Industries Software Joint Laboratory for Digital Shipbuilding provides a platform for faculty members and students of the School of NAOE to experience and practice digitalization throughout the ship lifecycle, including digital design, simulation and optimization with NX and data management using Teamcenter® software.

Training in the lab

“The marine industry is still largely relying on traditional design methods, including 2D drawing review and structural design, which are not only very inefficient but also prone to design errors and repeated rework,” says Liu. “What’s more, functions of some traditional ship design software are normally quite closed and inefficient to execute, hindering the improvement of design efficiency.

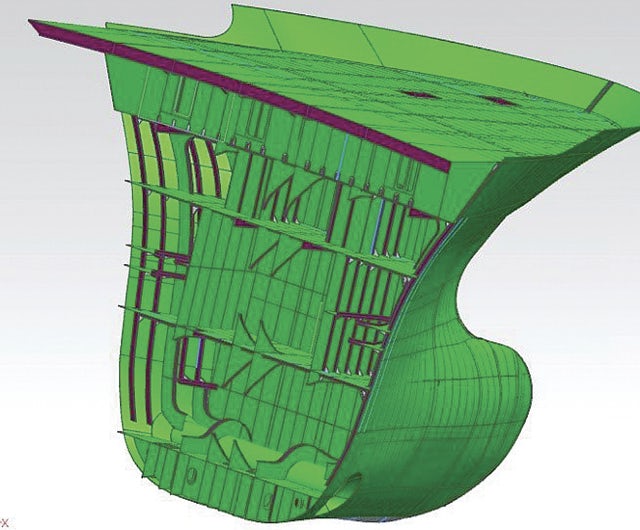

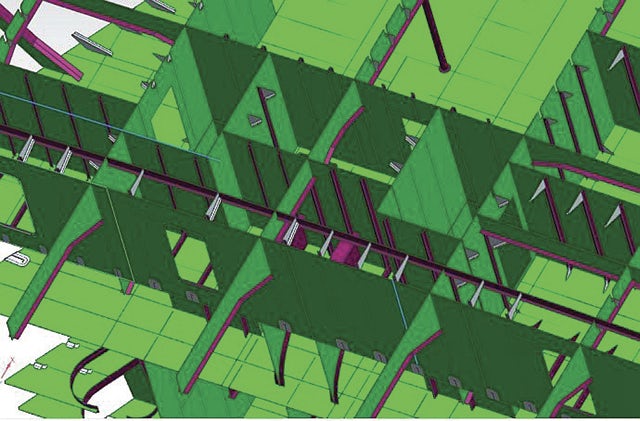

“Using Siemens Digital Industries Software’s NX software, the 3D design environment enables you to discover product functional and structural problems early in the design process, thus avoiding rework later on. In the meantime, for digital modeling of large, complex hull structures, the functionality of software from Siemens Digital Industries Software has also been a significant enhancement, greatly improving design efficiency.”

Liu cited a typical example: “For a graduation project or a course project in the past, students would normally make do with simple ship lines design and structural design, and avoid outfitting design because outfitting is far more complex and is very difficult to finish within a limited timeframe using traditional design methods, let alone visualize it.

“But with Siemens Digital Industries Software’s NX, we encourage students to do outfitting design, adding a lot of pipelines, stairs, doors and windows to the hull that can be visualized in the 3D environment. What you see is what you get. This way we have significantly reduced design errors and improved the teaching results at the same time.”

After two years of explorative cooperation with the help of the joint laboratory, the School of NAOE has deployed NX on a large scale; from conceptual design and scheme design to detailed design, students understand the theories and methods of 3D design, and attempt to apply the simulation and analysis technology in structural design. With the use of Siemens Digital Industries Software’s digital solutions, the School of NAOE has made material progress in the teaching of hull design and construction, outfitting design and shipbuilding mode, etc.

Promoting in-depth industry- university-research collaboration

In the global shipbuilding industry, the naval block construction and modular production sectors with digital technologies at their core are flourishing, which not only involves changing ship design and construction technologies, but also requires changes to the production organization and the approach to quality management. The serial operation mode based on the type of work that prevailed in the past has been replaced by a multi-type parallel operation mode by block and module, significantly shortening the construction cycle and enabling revolutionary development of the shipbuilding industry. Most shipyards in China started their journey to digitalization by using computer-aided design (CAD, computer-aided engineering (CAE) and computer-aided manufacturing (CAM), and some major pioneering enterprises have been moving toward fully digitalized shipbuilding or virtual shipbuilding, determined to realize full lifecycle management integration development, design, construction, inspection and acceptance.

Since an enterprise’s capability for transferring technological achievements and applying R&D achievements is usually limited, the process often involves in-depth industry-university-research cooperation. In the cooperation between shipbuilding enterprises and research institutes/universities, enterprises put forward technical requirements, while research institutes or universities provide technical services, facilitating the industrialization of scientific research results. That is why the School of NAOE has maintained a long-term industry-university-research collaboration with two major ship development and design institutes, and is exploring opportunities for cross-regional university-enterprise cooperation. The establishment of the HUST-Siemens Digital Industries Software Joint Laboratory for Digital Shipbuilding has been a real help in facilitating the deepening of such industry-university-research collaboration.

“In 2017 the School of NAOE plans to apply for the setup of a Hubei Intelligent Manufacturing Engineering Center, and conduct in-depth technical cooperation with enterprises like Xiamen shipyard,” says Liu. “In our university-enterprise cooperation, in addition to ship design and optimization using NX software, what’s more important is to realize full lifecycle data management leveraging Teamcenter to help enterprises realize digitalization throughout the entire shipbuilding process.”

Looking into the future of the joint laboratory, Jingxi says, “We will continue to use industry software solutions from Siemens Digital Industries Software to support teaching and scientific research, and we hope that Siemens Digital Industries Software can help the School of NAOE train more teachers with digital shipbuilding expertise to expand coverage.

“In the meantime, we also hope that the teaching and scientific research work will mean that we further implement Teamcenter data management into the existing 3D ship design environment, and that we even bring in the Tecnomatix® portfolio digital shipbuilding modules with the help of Siemens Digital Industries Software. It’s not only what the current industry-university-research collaboration needs rather urgently, but also the key to cultivating future-oriented digitalization talents.”

But with Siemens Digital Industries Software’s NX, we encourage students to do outfitting design, adding a lot of pipelines, stairs, doors and windows to the hull that can be visualized in the 3D environment. What you see is what you get. This way we have significantly reduced design errors and improved the teaching results at the same time.

Huazhong University of Science and Technology