Pozyskiwanie dostawców, komunikowanie się z nimi i współpraca

Nadzoruj interakcje dzięki rozwiązaniom, które zapewniają proste, responsywne i bezpieczne zarządzanie dostawcami.

Zintegruj partnerów ze swoim środowiskiem Teamcenter

Usprawnij współpracę z dostawcami, tworząc bezpieczne obszary robocze w oprogramowaniu Teamcenter. Zarządzaj umowami czasowymi i zapewnij dostawcom dostęp tylko do właściwych danych oraz ochronę poufności danych od innych dostawców. Ułatwiaj dostawcom dostęp do danych dotyczących rozwoju produktu w miarę ich ewoluowania, aby umożliwić wspólne podejmowanie właściwych decyzji projektowych.

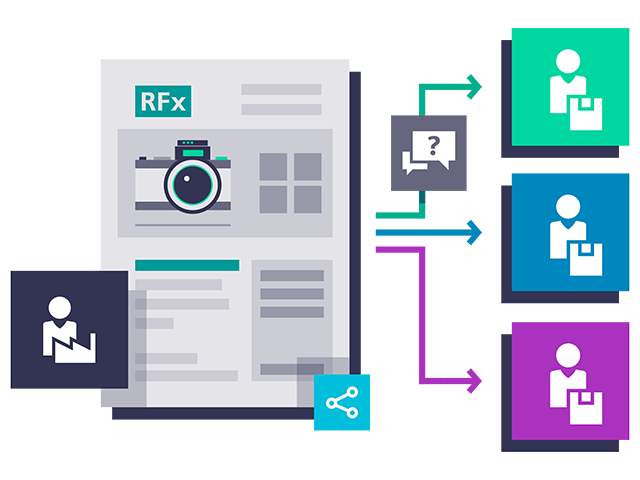

Cyfrowe zarządzanie całym procesem zaopatrzenia u dostawców

Uprość procesy RFx i zaopatrzenia dzięki funkcjom bezpośredniego pozyskiwania materiałów. Zarządzaj bazą danych dostawców i wysyłaj prośby dotyczące zaopatrzenia do dostawców spełniających określone kryteria. Generuj dokumenty RFI/RFQ/RFP i udostępniaj je potencjalnym dostawcom. Wykorzystuj szablony kwestionariuszy i obsługuj wiele rund procesu ofertowego. Monitoruj i porównuj odpowiedzi dostawców oraz nawiązuj współpracę z najlepszymi z nich.

Szybkie i bezpieczne wymienianie danych CAD i innych danych projektowych

Usprawnij cykle projektowania i przeglądu produktów dzięki funkcjom wymiany danych projektowych. Zapraszaj dostawców do współpracy nad wybranymi plikami za pośrednictwem bezpiecznego, samoobsługowego portalu internetowego połączonego z dzierżawcą Teamcenter. Monitoruj uprawnienia dostępu i bezpiecznie wymieniaj dane z dostawcami dzięki identyfikowalności i kontroli wersji. Współpracuj równolegle z autoryzowanymi dostawcami aktywnie korzystającymi z danych referencyjnych.

Callaway Golf

Callaway Golf drives innovation with NX and Teamcenter

Firma:Callaway Golf

Lokalizacja:California, USA

Siemens Software:NX