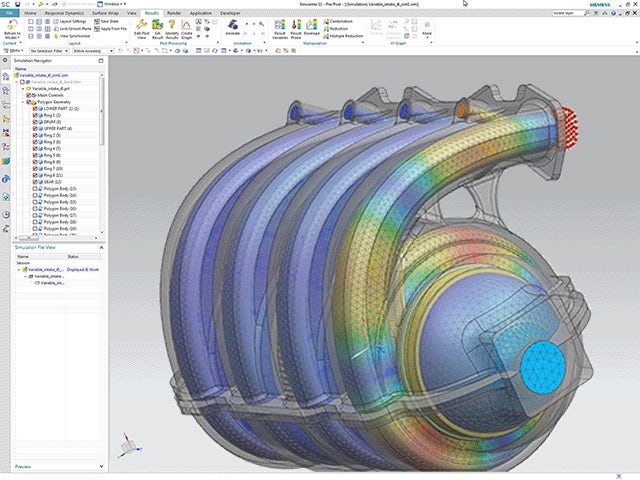

Zrozumienie i zapewnienie wydajności międzydomenowej wymaga rozwiązań symulacyjnych i testowych, które można wdrożyć we wszystkich fazach rozwoju oraz we wszystkich domenach wydajności i fizyce. Co więcej, działania te muszą być ze sobą powiązane, a nie prowadzone niezależnie, aby uchwycić rzeczywiste zjawiska multifizyczne i zrównoważyć sprzeczne atrybuty. Simcenter oferuje zintegrowane portfolio najlepszych w swojej klasie rozwiązań do symulacji predykcyjnych, testów i eksploracji projektów, które obejmują wszystkie fazy procesu rozwoju produktu w celu rozwiązania najtrudniejszych problemów inżynieryjnych, mogą pomóc w transformacji inżynierii poprzez zwiększenie produktywności i wspieranie innowacji.

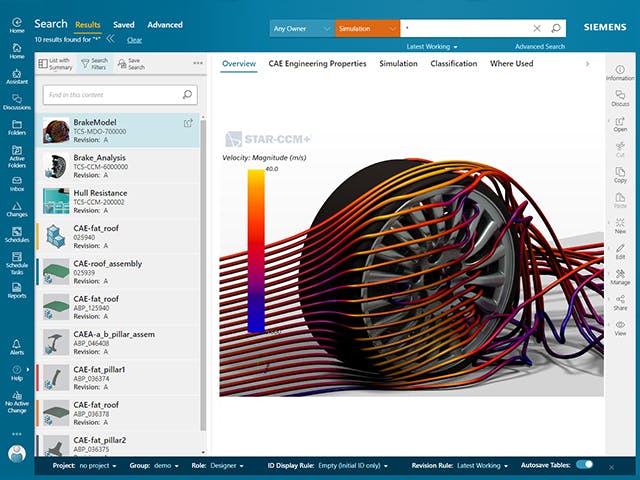

Symulacja i testowanie nie mogą być już postrzegane jako działania odizolowane. Cyfrowy bliźniak zapewnia wartość w całym cyklu życia, a jego ewolucją należy zarządzać w celu zapewnienia identyfikowalności i wpływu zmian. Jest to możliwe tylko dzięki przeprowadzeniu symulacji i testów w ramach ogólnej inicjatywy rozwoju produktu cyfrowego. Siemens Xcelerator zaciera granice między dziedzinami inżynierii, takimi jak elektryka, mechanika i oprogramowanie, a rozwiązania symulacyjne i testowe Simcenter uzupełniają rozwiązania Siemens Xcelerator w projektowaniu, realizacji i optymalizacji faz cyklu życia.

Na drodze do cyfrowej transformacji firmy potrzebują niezawodnych partnerów dysponujących zasobami, które pozwolą im stale wprowadzać innowacje w zakresie narzędzi i aplikacji. Siemens wydaje znaczne środki na badania i rozwój, wykorzystuje partnerstwa z firmami o ugruntowanej pozycji w sąsiednich obszarach i inwestuje w start-upy, które dysponują technologiami, które mogą przekształcić biznes w przyszłości. Wszystko to zapewnia stały dopływ innowacji, które mogą pomóc naszym klientom pozostać w czołówce i czerpać korzyści z cyfryzacji szybciej niż ich konkurenci. Usługi inżynieryjne i konsultingowe Simcenter zapewniają głęboką wiedzę domenową, obiekty, zasoby i doświadczenie, aby przyspieszyć transformację procesów inżynieryjnych i wynikający z niej zwrot z inwestycji.